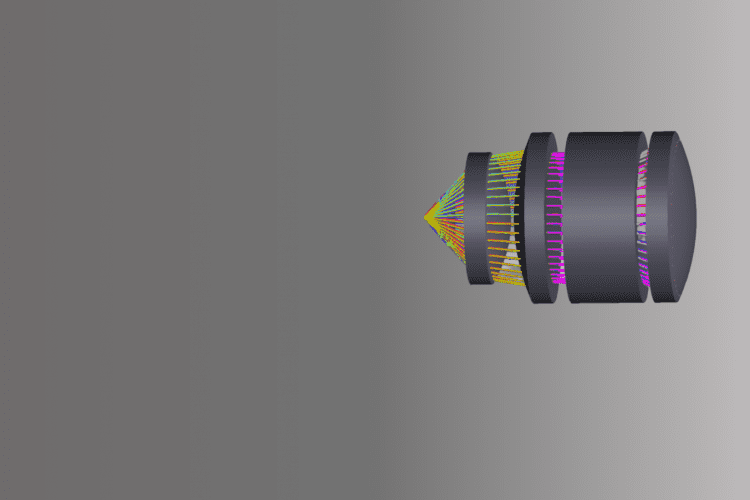

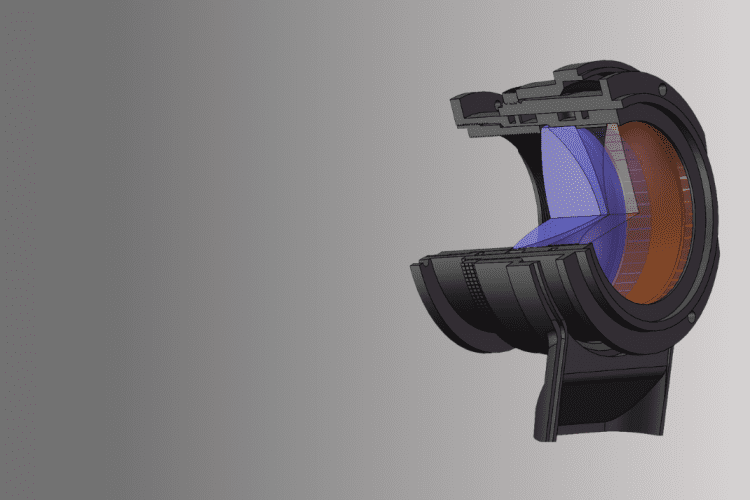

Key Takeaways Reverse Optical Engineering is pivotal for recreating or enhancing optical components, especially when original designs are unavailable or are in need of improvement. This case study showcases the necessary steps in lens reverse engineering, from customer collaboration and sample testing to optical path simulation and final lens assembly. Using advanced tools and iterative […]