BK7 Windows: Optical Characteristics and Utilizations

A BK7 Window stands as an optical aperture crafted from premium Schott glass. These windows boast exceptional optical properties, providing consistent light transmission across the visible spectrum and into the near-infrared region. They exhibit an impressive refractive index uniformity and a crystal-clear, nearly colorless appearance.

Our BK7 windows are meticulously fabricated from Schott Optical borosilicate-crown glass, distinguished by its near absence of bubbles or impurities, derived from exceptionally pure source materials.

Avantier’s BK7 windows are ideally suited for rigorous optical applications, attainable with laser-grade precision. BK7 glass boasts a density of 2.51 g/cm³ and a Knoop hardness rating of 610. Its coefficient of thermal expansion measures approximately 7.1 x 10^-6 K in the range from -30 °C to +70 °C, and about 8.3 x 10^-6/K from +20 °C to +300 °C.

Should your requirements necessitate enhanced ultraviolet (UV) transmission or a reduced coefficient of thermal expansion, we recommend considering our UV fused silica windows instead.

BK7 windows exhibit remarkable resistance to staining and moderate resistance to acids, typically categorized as grade 1 on the SR (stain resistance) scale, which ranges from 0 (high) to 4 (low). In terms of resistance to alkali reagents, it is classified as class 2 on the AR (alkali resistance) scale, which also spans from 0 (high) to 4 (low).

Our standard for BK7 windows mandates a clear aperture exceeding 85 percent of the aperture diameter. Diameter tolerances stand at +0.0, -0.05mm, with thickness tolerances of +/- 0.1mm.

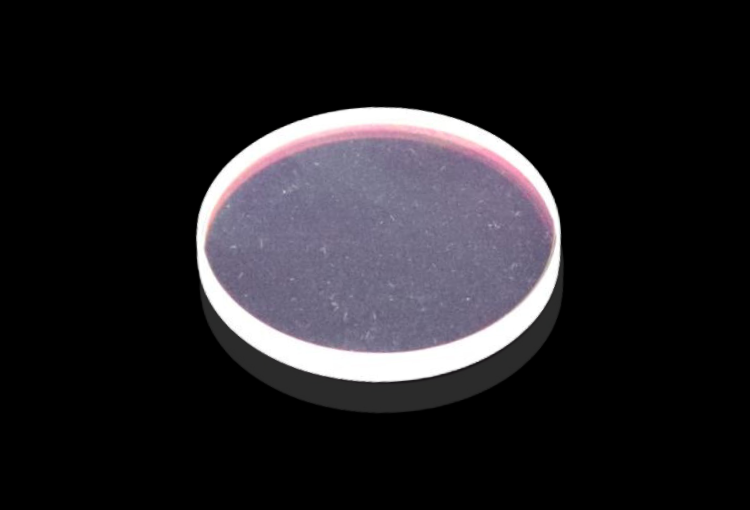

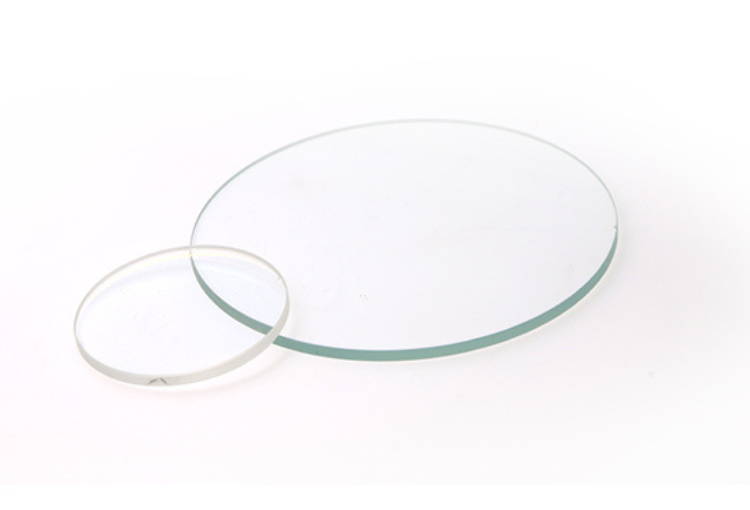

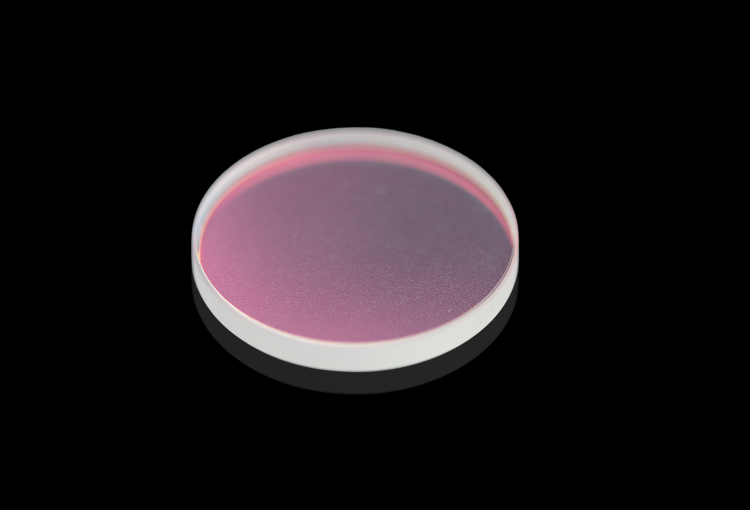

Various types of BK7 Windows

Surface Quality Specifications for BK7 Windows

The surface quality of our optical windows is determined using a two-part scratch dig number system, in accordance with U.S. Military Performance Specification MIL-PRF-13830B. The first number characterizes the brightness of scratches, denoted as 10, 20, 40, 60, or 80, with higher values indicating more pronounced scratch brightness. These are calibrated by comparison with reference scratches.

A “dig,” which represents a pit or small crater on the glass surface, is defined by its diameter. The dig number corresponds to the actual size of the largest permissible dig, specified in hundredths of a millimeter. In cases of irregularly shaped digs, the diameter is calculated as half of the length + width.

For most applications, standard quality falls within the 40-20 range, while laser applications demand a minimum surface quality of 20-10. Our BK7 windows adhere to a factory standard of 10-5 scratch dig, signifying precision laser quality. This ensures their suitability even for high-power or UV laser applications. The high surface quality also minimizes wavefront distortion and light scattering when optical radiation passes through our windows. According to our factory standards, the maximum allowable wavefront distortion is λ/10 per 25mm.

Customization Options

Our BK7 windows are available with or without anti-reflective (AR) coatings, and an optional protective bevel. We maintain a stock of circular windows ranging from 3.5 to 25.4 mm in diameter and 1-3 mm in thickness. Additionally, square BK7 windows with similar dimensions can be accommodated.

Our dedicated design team is ready to assist you at every stage of your optical system design. Please feel free to reach out for a complimentary consultation and to discuss any specific custom requirements you may have. Our cutting-edge machinery and metrology equipment enable us to produce precise, high-quality optics tailored to your unique application.

Material |

BK7 |

Irregularity (fringe) |

l/10 |

Diameter Tolerance |

+0.0, -0.05mm |

Thickness Tolerance |

+/- 0.1mm |

Clear Aperture (%) |

C>85% |

Parallelism |

1 arcmin |

Surface Quality |

10-5 scratch and dig |

Wavefront Distortion |

l/10 per 25mm |

Contact us today to discuss your optical needs and find the perfect window for your requirements.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.