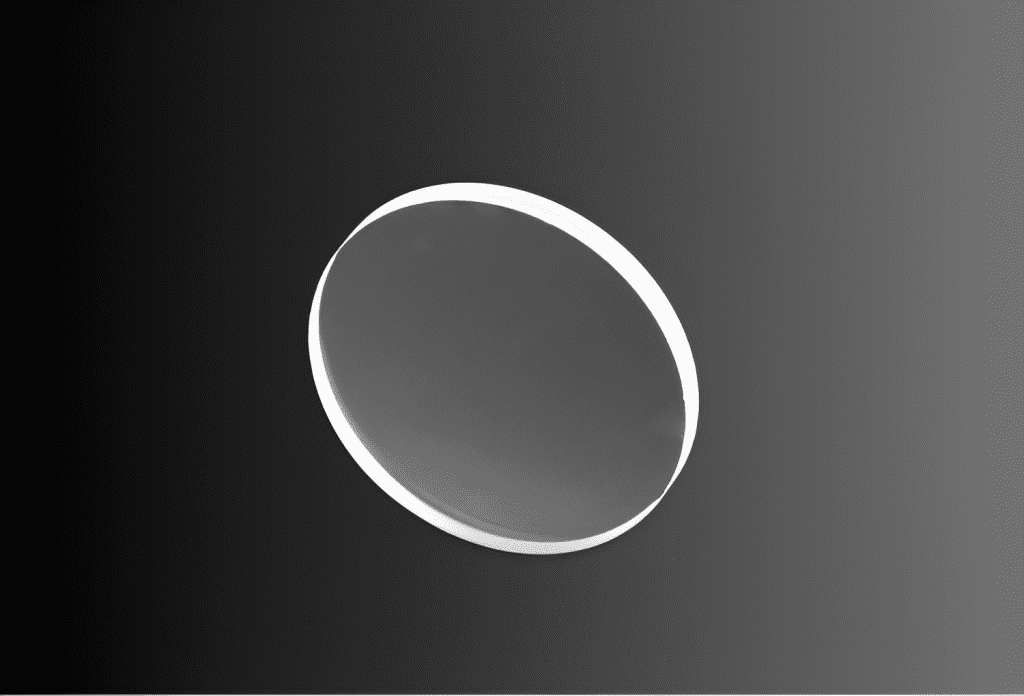

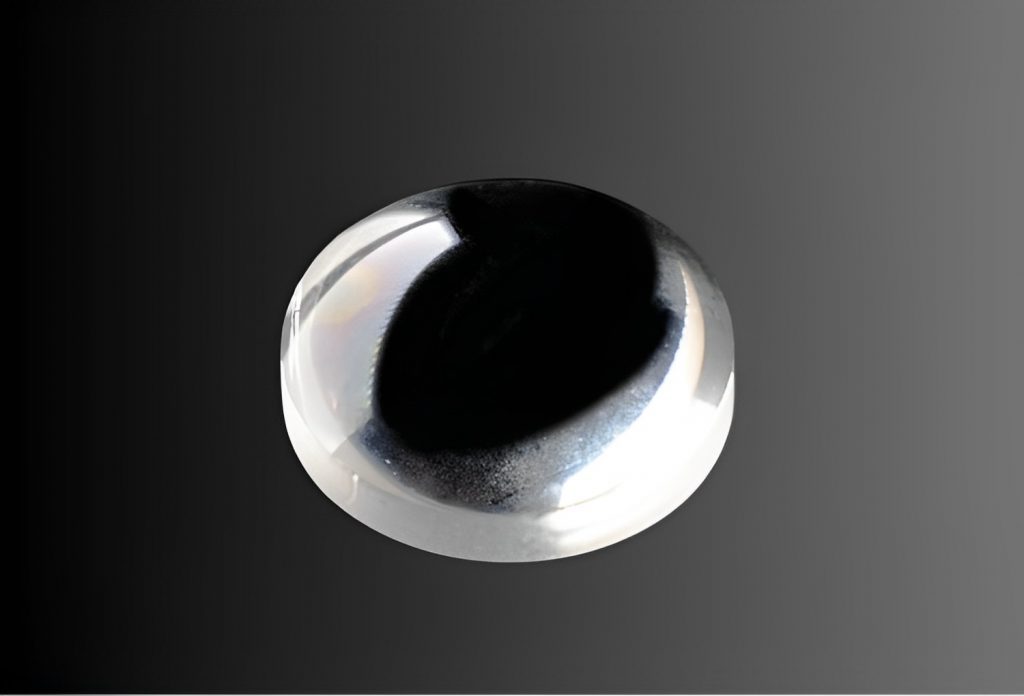

Avantier specializes in the manufacturing of high-quality plano-convex lenses, which are optical lenses with a positive focal length. These lenses are versatile and can be tailored to suit your specific application by offering a wide range of sizes, substrates, and coatings.

Applications and Suitability for Plano-Convex Lenses

Plano-convex lenses are ideal for infinite conjugate systems and simple imaging tasks. They are well-suited for applications involving monochromatic illumination and light collimation. Collimated light refers to light whose rays are parallel and spread minimally as it propagate. This is crucial in applications where precision and minimal divergence are required. Due to their design, with one flat surface and one convex surface, the orientation of the lens is crucial. In most cases, the flat surface should be oriented towards the focal plane.

Versatile Applications

Our lenses are highly versatile and find applications across various industries, including industrial, robotics, pharmaceutical, and defense sectors. When utilized in laser cutting, plano-convex lenses are most effective for high-power cutting applications and when dealing with thick materials. In such scenarios, the plano-convex lens provides a wider cut width, enabling the laser’s oxygen assist to enter the cut and enhance the cutting process. Additionally, these lenses offer a greater depth of field, resulting in a taperless edge.

Substrate Influence and Optical Properties

The specifications of plano-convex lenses are dependent on the substrate used, influencing properties such as the index of refraction, Abbe number, laser damage threshold, Knoop hardness, and scratch resistance.

The index of refraction of our optical components typically ranges from approximately 1.4 to 4. The commonly used N-Bk7 substrate, suitable for visible light applications, has an index of refraction of 1.517. Conversely, Germanium exhibits an extreme index of refraction of 4.003. Inhomogeneity refers to the variation of the index of refraction within a glass. An inhomogeneity class of 0 signifies a maximum permissible variation of +/- 50 x 10-6, whereas an inhomogeneity class of 5 indicates a maximum permissible variation of +/- 50 x 10-6.

- Abbe Number and Dispersion: The Abbe number of a plano-convex lens indicates its level of dispersion. It is calculated by comparing the refractive index of the substrate at three benchmark wavelengths: f (486.1nm), d (587.6nm), and c (656.3nm). A higher Abbe number implies lower dispersion characteristics of the substrate. The Abbe numbers of optical glasses typically range from 20 to approximately 65. Glasses with Abbe numbers below 50 are classified as flint glasses, while those with Abbe numbers exceeding 55 are known as crown glasses.

- Laser Damage Threshold: Laser damage threshold is a critical specification for laser-grade optics, quantifying the laser power per area that the glass surface can withstand without damage. For instance, an optic with a damage threshold rating of 0.5 J/cm2 @ 150 femtosecond pulses and 100 kW/cm2 CW should endure 0.5 J per square centimeter from a high-repetition femtosecond pulse laser or alternatively, 100 kW per square centimeter from a high-power continuous wave (CW) laser.

- Additional Specifications: Additional specifications of plano-convex lenses encompass size, radius of curvature, center thickness tolerance, surface finish, and surface quality. Our team of optical designers is available to collaborate with you in designing your system, and we can produce precision lenses customized to your specific requirements.

Plano Convex Lens Manufacturing Capabilities

| Specifications | Factory Standards | Manufacturing Limit |

| Dimension Tolerance | +/-0.05mm | +/-0.01mm |

| Center Thickness Tolerance | +/-0.05mm | +/-0.01mm |

| Radius Tolerance | +/-0.3% | +/-0.2% |

| Surface Quality(S/D) | 40-20 | 10-5 |

| Irregularity | 1/4 Lambda | < 1/10 Lambda |

| Centration(arc min) | 3′ | 1′ |

Various Types of Plano Convex Lenses

Customize your own plano-convex lenses

In addition to our standard offerings, we take pride in our ability to provide customized solutions to meet our customers’ unique requirements. We understand that each application may have specific demands and parameters that need to be addressed. Therefore, our team is equipped to collaborate with you in order to tailor the plano-convex lenses precisely to your needs.

Whether it involves adjusting the size, radius of curvature, center thickness tolerance, surface finish, or surface quality, we have the expertise to deliver custom-manufactured lenses that align with your specifications. Our optical designers are ready to work closely with you, leveraging their knowledge and experience to design a system that optimally suits your application.

By offering this level of customization, we strive to ensure that our customers receive the highest quality plano-convex lenses that not only meet but exceed their expectations, enabling them to achieve their desired outcomes with utmost precision and performance.

Contact us today if you’d like to discuss a custom order or your next project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.