Polymer Optics

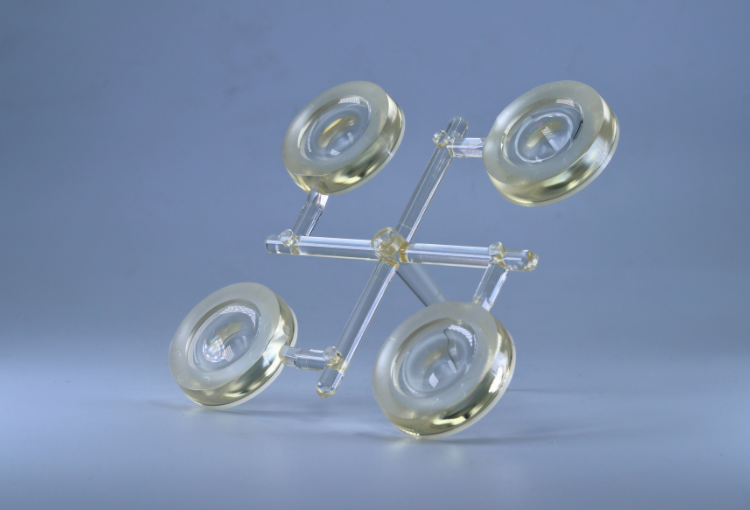

The manufacture of precision polymer optics is a fast-growing field, as designers seek lightweight lenses and components that can be molded to their exact specifications. Polymer optics are special optics manufactured from amorphous polymer materials such as polycarbonate (PC), polymethyl methacrylate (PMMA/acrylic), polystyrene, and liquid silicone. Cyclic olefin polymers are another option often chosen for good chemical and heat resistance and high optical clarity. Only the highest quality polymers can be used for manufacturing optical polymer components, and the production process is a highly controlled one.

At Avantier, we produce custom polymer optics for a wide variety of applications. More than two decades of experience in North America in optical design and manufacturing enables our team to produce high-performance optics suitable for even the most demanding applications, and we’re proud of our track record of excellence.

Applications of Polymer Optics

Polymer optics are lower density than traditional glass optics, and so can be produced with lower weights. They’re sturdy, easy to handle and easy to integrate mechanically into optical systems. They can be produced at a lower cost and in a shorter time frame than glass optics, and can be produced in spherical, aspheric, or free form. Different plastic materials have different refractive index, and some have very good optical qualities. All this means that polymer optics have become ubiquitous in consumer and optical systems. Polymer optics have an important place in:

- Machine vision (including LIDAR and other time-of-flight applications)

- Security and defense

- Communication and information technology

- Semiconductor industry

- Medical technology

- Optical storage devices

- Scientific research (for example, in spectrometers and cleanroom particle counters)

Manufacturing Polymer Optics

Polymer optics are typically formed with injection molding, where a liquified polymer substrate (melted thermoplastic) is injected into carefully prepared optical molds. These molds may be single or multi-cavity, and must be crafted by skilled optical engineers using state-of-the-art equipment. The molding process After being manufactured, each optic is subjected to extensive testing to make sure it meets all applicable standards and will perform as expected in the environment it has been designed for.

Polymer Optics at Avantier

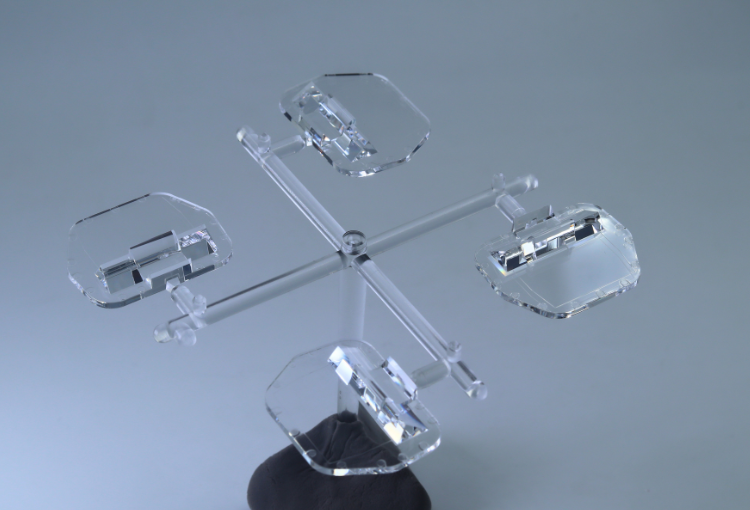

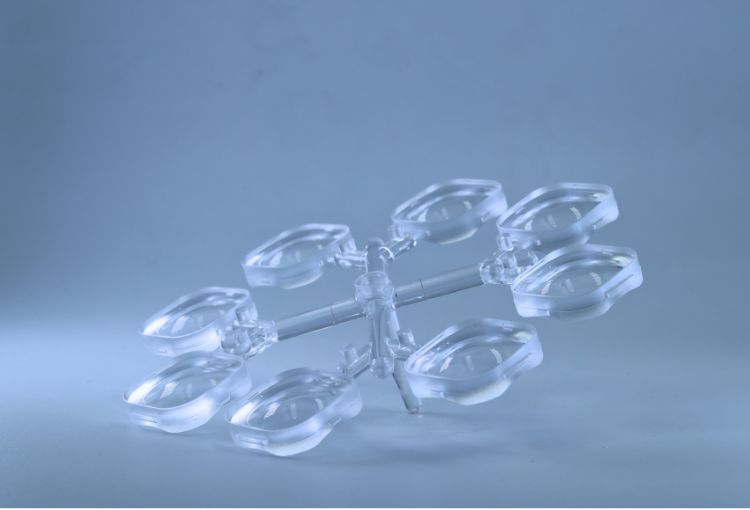

At Avantier we produce custom polymer optics components and assemblies designed to meet the exact needs of our clients. Whether you need aspheric lenses, optical prisms, cylinder lenses, toroid lenses, or lens arrays, we can get you what you need. We can step in at whatever stage you are in the process: whether you have a detailed design of the piece you need and know exactly what substrate will work best in your situation, or whether you are at the very beginning stages and need help coming up with an initial design that fits your application.

Our highly skilled team of optical designers and engineers are available to work with you and help you determine exactly what part you need for your optical systems, and we are able to manufacture high-performance parts with a very low turnaround time. Contact us today to place an order or schedule your first consult.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.