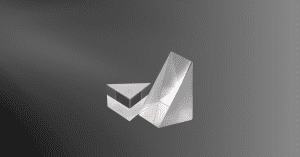

Dove Prisms

Dove prisms are specialized optical components utilized across diverse fields such as astronomy, interferometry, and pattern recognition. They are used to rotate, invert, or retroreflect an image depending on the prism rotation angle and the surface through which the light enters the prism.

When light enters through the longest faces of the prism, it is reflected back and flipped 180°, while the top surface remains unpolished. Light propagates along the longitudinal axis of a Dove prism, reflecting once from the bottom face, thus inverting the image on the other side. Rotating the prism about its longitudinal axis rotates the image at twice the rate of the prism’s rotation angle. Possessing distinctive attributes, this prism is adept at image rotation, retroreflection (the reflection of an image back to its source), and image inversion. Its configuration resembles a right-angle prism with its upper section truncated.

Specifications

Avantier provides specifications for dove prisms, encompassing the following key features:

- Rotation of the prism will result in a 60-degree image rotation.

- Material Options: Dove prisms are typically made from materials such as BK7 grade A optical glass, Corning Fused Silica 7980, JGS1 UV grade fused silica, and JGS2.

- Dimension Tolerance: The dimension tolerance specifies the acceptable variation in the prism’s dimensions. Our factory standard for dimension tolerance is +/- 0.1 mm, and tighter tolerances can be provided upon request.

- Angle Tolerance: The angle tolerance is typically less than 5 arc minutes, indicating the allowable variation in the angles.

- Flatness: The flatness of a prism is the deviation of each of its surfaces from an ideal flat surface. Our factory standard is l/4l at 632.8 nm.

- Coating: Both coated and uncoated dove prisms are available upon request.

Surface Quality: The surface quality of a prism is described by a scratch and dig rating. A 60-40 scratch and dig rating, which is the factory standard, ensures highly polished surfaces with defined criteria for scratches and digs.

Factory Standard

Material | BK7 Grade A optical glass, Corning Fused Silica 7980, JGS1, JGS2 |

Clear Aperture | >90% |

Dimension Tolerance | +/-0.1mm |

Angle Tolerance | <5 arc minutes |

Flatness | l/4l @ 632.8 nm |

Surface Quality | 60-40 |

Coating | On request |

Applications

Dove prisms are used as image rotators. They have various applications due to their ability to rotate or invert images without lateral transposition or deviation. They are commonly employed as image rotators in optical-mechanical systems. This type of prism was invented by Heinrich Wilhelm Dove, a Prussian meteorologist and physicist, and has found important applications in optical instruments and systems that require image manipulation and reflection.

Custom Dove Prisms at Avantier

At Avantier, we manufacture custom dove prisms, carefully designed and crafted to meet the precise specifications of our valued customers. Whether you have a blueprint you’d like produced or simply a general idea of your custom dove prism requirements, our engineers and designers are ready to collaborate with you to bring your vision to life. Contact us today to schedule your initial consultation or place a custom order.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.