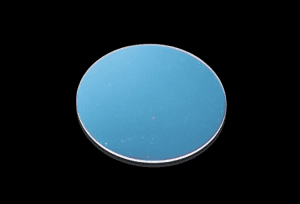

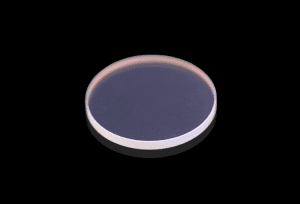

CaF2 Optical Windows

A CaF2 optical window, crafted from crystalline calcium fluoride, boasts a versatile nature along with robust environmental stability and laser damage resistance. These windows excel in maintaining a high, consistent transmission spanning from 200 nm to approximately 7 μm. Avantier specializes in crafting top-tier custom CaF2 windows tailored for UV and IR applications. With a substantial inventory of various window types readily available, we possess the capability to manufacture windows that align precisely with your unique specifications.

CaF2 Window Properties

CaF2 exhibits optical characteristics akin to BaF2 but surpasses it with a Knoop hardness of 158.3, making it nearly twice as tough. Additionally, it boasts a lower density, with CaF2 registering at 3.18 g/cm3 compared to barium fluoride’s 4.89 g/cm3. CaF2 optics typically offer a more cost-effective solution compared to their BaF2 counterparts, as the optical crystalline substrate occurs naturally. While pure calcium fluoride is transparent, naturally mined CaF2 used for optical windows may display absorption bands around 300 nm due to impurities. Calcium fluoride also possesses a low refractive index of 1.39908 at 5 μm.

Environmental Resilience

CaF2 exhibits resistance to water, HF, and many acids, although it dissolves slowly when exposed to nitric acid. Under room temperature and 100% humidity conditions, a CaF2 window remains free from fogging, and its polished surface remains unaffected under standard operational circumstances. However, when subjected to temperatures exceeding 600°C in the presence of moisture or humidity, significant degradation can be expected. Nevertheless, in a dry environment, these windows can be employed up to 1000°C.

Temperature Characteristics of CaF2 Windows

In dry conditions, CaF2 maintains its form and optical properties until reaching approximately 800°C. At higher temperatures, it may be susceptible to thermal shock, yet it proves less sensitive to temperature fluctuations compared to BaF2. Its coefficient of thermal expansion stands at 18.85 x 10-6/°C, with a melting point of 1360°C.

Applications of CaF2

CaF2 finds frequent application in spectroscopic windows and cryogenically cooled thermal imaging systems, particularly in scenarios demanding broad transmittance capabilities.

The exceptional damage threshold and minimal UV absorption of calcium fluoride render uncoated CaF2 windows an ideal choice for excimer laser optics. These specialized UV laser systems play pivotal roles in micro-machining devices and eye surgery procedures. We take pride in the precision polishing of each CaF2 window, ensuring the high surface quality required for these exacting laser applications. Our commitment to quality assurance is unwavering, supported by state-of-the-art metrology equipment to verify that every window produced in our facility fully complies with relevant standards.

Material |

CaF2 |

Irregularity (fringe) |

l /4 |

Diameter Tolerance |

+0.0, -0.05mm |

Thickness Tolerance |

+/- 0.1mm |

Clear Aperture (%) |

>85% |

Parallelism |

5 arc min |

Surface Quality |

40-20 |

Wavefront Distortion |

l/4 per 25mm |

Feel free to reach out to us for inquiries about manufacturing limits or custom specifications. Our dedicated design team is eager to collaborate with you in identifying the optimal optical solution tailored to your specific application. Leveraging our extensive array of precision equipment, we have the capability to craft top-quality windows that align precisely with your requirements. Additionally, we offer a selection of CaF2 lenses and prisms to cater to your diverse optical needs.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.