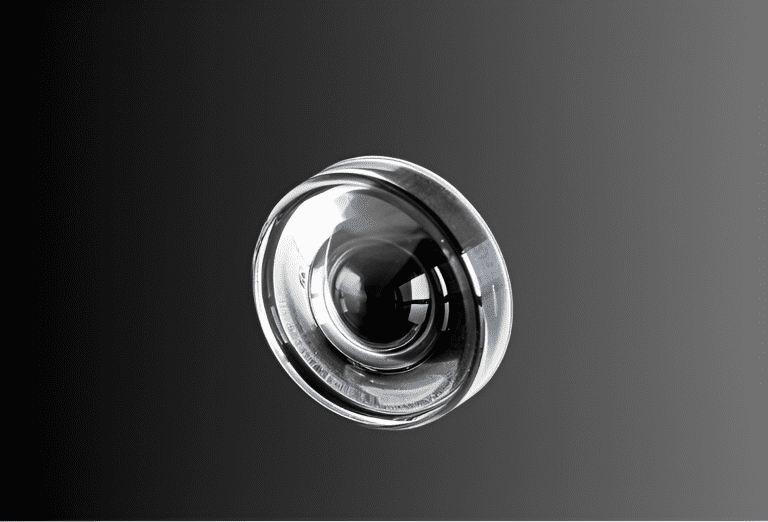

Aspheric Lenses

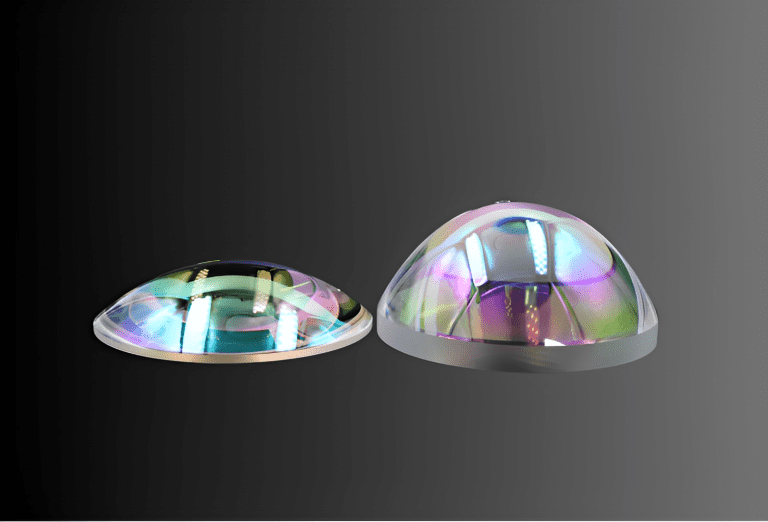

An aspheric lens is an optical lens with a non spherical surface profile; its surfaces are not portions of a sphere or cylinder. There are many types of custom aspheric lenses with various geometries. Unlike spheric lenses, they do not have a constant radius of curvature. They are designed to eliminate almost all spherical aberration, and by light focused to a small single point they drastically decrease the amount of blur and so improve image quality. Using aspheric lenses typically results in more compact assemblies as there are fewer aberrations to be corrected for. As an aspheric lens manufacturer, Avantier manufactures a wide variety of custom aspheric lenses solutions for applications from smartphones to lasers and fiber optics, from research and industry to medicine.

Our lenses are available with anti-reflection coatings or in uncoated forms, in glass, crystalline, or plastic substrates. State of the art grinding and polishing metrology equipment, including computer-controlled precision polishing devices and magneto-rheological finishing (MRF) technology, enable us to ensure that the surface quality is optimized for your application. MRF technology enables high-performance finishing results in significantly less time compared to conventional polishing methods due to its precise control of the removal location and rapid removal rate.

What Is An Aspherical Lens?

Aspheric lenses are precision-grade optical components with a complex, non-spherical surface designed to minimize or eliminate optical aberrations, particularly spherical aberration. This aberration occurs when light rays passing through the edges of a spherical lens focus at a different point than those passing through the center, resulting in a blurry image. The comparison of spherical vs aspherical lenses highlights that aspheric designs correct this by gradually changing curvature from the center to the edge, ensuring all light rays converge at a single focal point. This makes them ideal for applications like laser beam collimation, where precise beam shaping is critical.

Aspheric lenses vs high index comparisons show that while high-index lenses rely on material properties to bend light more effectively, precision-grade aspheric lenses optimize the lens surface shape to enhance optical performance. Similarly, aspheric lenses vs pancake lenses considerations demonstrate that pancake lenses are designed for compactness, whereas aspheric lenses prioritize image quality and sharpness. Aspherical lenses benefits include sharper images, reduced distortion, and superior correction of spherical aberration, allowing optical systems to achieve high performance with fewer lens elements—leading to smaller, lighter, and potentially more cost-effective devices.

Types of Aspheric Lens

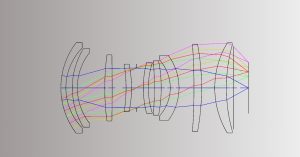

An aspheric lens may have any of a number of geometries. Most of them are rotationally symmetric but have a more complex front surface. Unlike a spherical lens, the curvature changes with the distance from the optical axis. Another way of putting this would be to say that the radius of curvature varies radially from the center of the lens.

Typically, the further from the optic axis, the weaker the curvature. A lens that does not have these symmetries is typically called a free-form optic.

Aspheric lenses are defined by their surface profile (sag of the surface parallel to the optical axis) or by means of orthogonal coefficients Qbfs and Qcon. Qbfs quantifies the RMS slope departure of your aspheric lens from a best fit sphere, and Qcon quantifies the sag departure from a base conic.

Features & Benefits

Aspheric lenses are optical lenses with non-spherical surfaces (aspherical surfaces), meaning they have a changing curvature across the lens rather than a constant curvature, as seen in spherical lenses. Because they contain controlled variations in curvature across the surface of the lens, they correct for the optical aberrations that occur with spherical lenses. Removing these aberrations has several important benefits:

- Improved image quality: The controlled curvature of an aspheric lens reduces the number of aberrations and improves overall image fidelity and clarity. This precision aspheric design ensures optimal performance in various applications.

- Focuses Light: The unique design of aspheric lenses focuses light more precisely than traditional spherical lenses, leading to enhanced clarity and reduced optical errors in various devices and applications.

- More Compact and Lightweight Design: The ability to control the lens surface curvature of aspheric lenses enables the design of thinner and flatter lenses, reducing the overall sizes and weights of optical systems. Furthermore, lens designs often require a greater number of lenses in order to compensate for the optical aberrations and improve optical quality. Because aspheric lenses solutions have fewer aberrations, designs utilizing these lenses can achieve high quality with fewer lenses. The compactness and weight reduction afforded by aspheric lenses are particularly advantageous in portable devices like cameras where size and weight constraints are critical.

- Increased Design Flexibility: Aspheric lenses have curvatures which can be adjusted as needed. The increased flexibility in designing the lens shape, curvature, and performance parameters enables optical engineers to optimize the performance of their systems. This design flexibility leads to more efficient and cost-effective optical systems with improved performance and reduced complexity.

By integrating controlled variations in curvature, optical engineers can utilize aspheric lenses to improve systems’ image qualities, create more compact and lightweight designs, and increase design flexibility.

Manufacturing Capabilities

| Diameter | 5 – 200mm |

| Diameter Tolerance | +0/-0.100mm – +0/-0.010mm |

| Asphere Figure Error (P – V) | 3μm – smaller than 0.06μm |

| Vertex Radius (Asphere) | ±0.5% – ±0.05% |

| Sag | 25mm max |

| Typical Slope Error | 1μm – 0.15μm per 1mm window |

| Centering (Beam Deviation) | 3 arcmin – 0.5 arcmin |

| Center Thickness Tolerance | ±0.100mm – ±0.010mm |

| Surface Quality (Scratch Dig) | 80-50, 40-20,10-5 |

| Aspheric Surface Metrology | Profilometry (2D & 3D) & Interferometry |

Custom Aspheric Lenses

Custom Aspheric Lenses have important applications in high precision imaging. From aerospace night vision imaging optics to defense imaging, from microscope imaging objectives to semiconductor wafer inspection tools, they are essential components of many precision imaging devices. For instance, the Smite Cassegrain telescope uses them as well as reflective elements to reduce aberrations and create a high-resolution image. Optics manufacturers often prefer these solutions for their ability to deliver superior performance in demanding environments.

Aspheric lenses are more expensive to manufacture than are spherical lenses, but for high performance optics the benefits are significant. They also are a good option where a small footprint system is required as the aspheric lens lends itself well to compact assemblies.

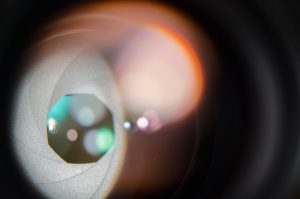

An aspheric camera lenses is a lens assembly that includes an aspheric lens among other components. The compact, lightweight assembly as well as the high image quality make these lenses highly desirable.

If you have more questions about custom aspherical optical solutions and manufacturing services, don’t hesitate to contact us. Our experienced optical designers are always available to discuss a custom order. If you are looking for stock options, visit Stock – Asphere Lenses.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.