Laser Lens Overview with Figures

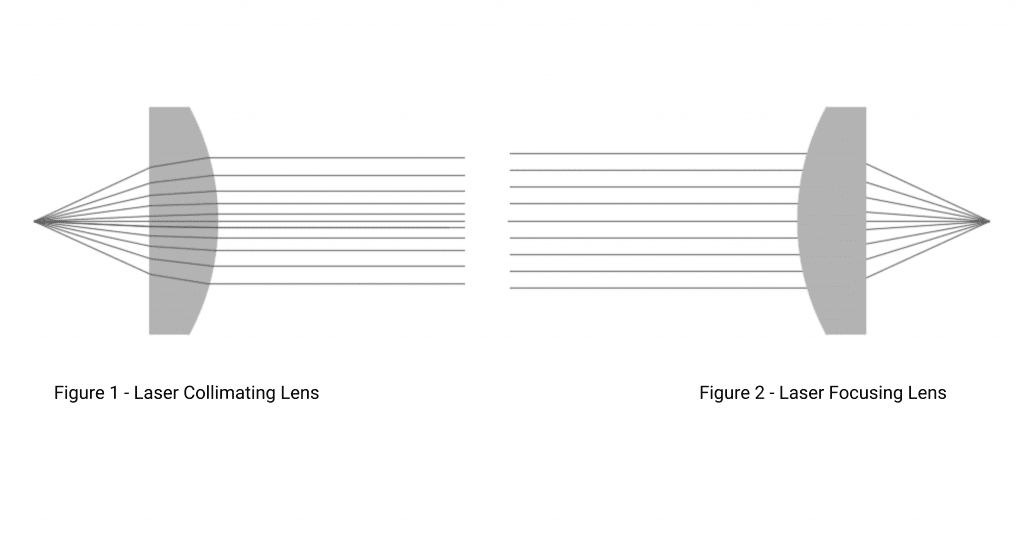

Laser lenses, as depicted in Figure 1 and Figure 2, are integral optical components employed within laser-based devices for a multitude of laser applications. These applications encompass, among others, laser illumination, laser collimation, laser scanning, laser dimensioning, material processing, laser welding, laser cutting, laser tracking, line/pattern generation, and more. A range of laser lens types exist, encompassing spherical lenses, aspherical lenses, cylindrical lenses, Axicon lenses, and Powell lenses. These lenses may be offered with or without antireflection coatings adorning their surfaces. The primary functions of laser lenses involve concentrating a laser beam into a minute focal point, producing a collimated laser beam from a laser source, generating a straight laser line from a collimated laser beam, and converting a laser beam into a ring-shaped focal point.

Laser Collimating Lens and Laser Focusing Lenses

A laser collimating lens, as illustrated in Figure 1, serves the purpose of generating a collimated laser beam from a laser source. The determination of the focal length for a laser collimating lens hinges upon factors such as the laser’s divergence angle (FWHM) and the desired diameter of the resultant laser beam. Conversely, a laser focusing lens, depicted in Figure 2, is employed to concentrate a laser beam into a small focal spot. The focal length of a focusing lens is contingent upon parameters such as the initial size of the laser beam, the desired spot size, and the required depth of focus. Various types of laser focusing and collimating lenses are available, including plano-convex lenses and aspheric lenses.

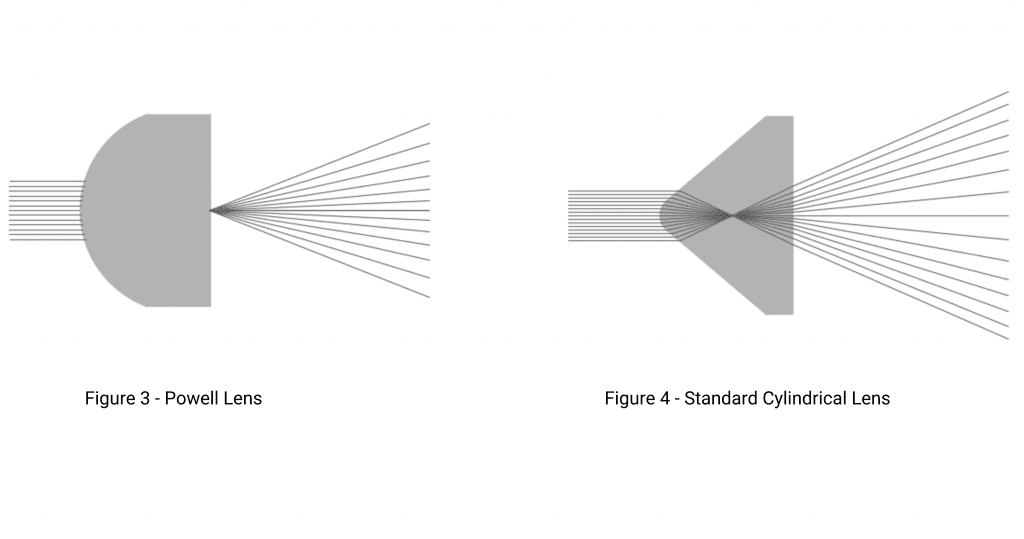

Laser Line Generator Lenses

A laser line generator lens serves the crucial role of transforming a collimated laser beam into a linear configuration. Notably, Figure 3 showcases a Powell lens utilized extensively for converting collimated laser beams characterized by Gaussian intensity distributions into straight and evenly distributed lines. In contrast to conventional cylindrical lenses that yield laser beam lines with Gaussian intensity profiles, Powell lenses exhibit the exceptional capability to generate laser lines with significantly more consistent energy dispersion across the line.

To achieve optimal laser line quality, precise optimization of the Powell lens becomes essential, taking into consideration factors such as the dimensions of the laser beam and the desired divergence fan angle. Complementing this, Figure 4 highlights a standard cylindrical lens, providing a point of comparison within the context of laser line generation.

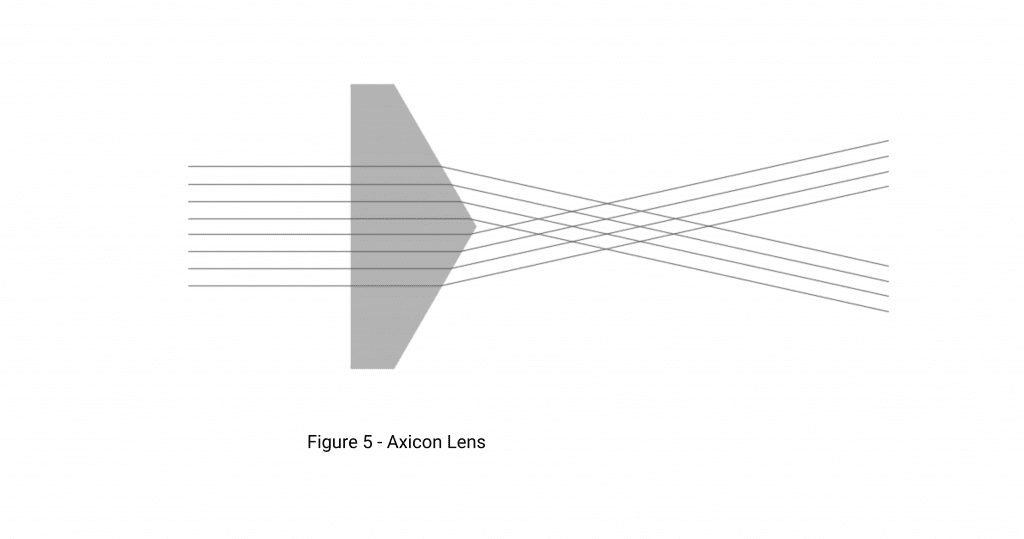

Laser Ring Generator Lenses

A laser ring generator lens, showcased comprehensively in Figure 5, belongs to the category of Axicon lenses, often referred to as conical lenses or rotationally symmetric prisms. These lenses serve the vital role of transforming a collimated laser beam into a distinctive ring-shaped focal spot or line. The defining feature of an axicon lens lies in its conical surface, diverging from the convention of curved surfaces seen in traditional lenses. The axicon lens typically boasts a plano-convex configuration, as exemplified in the provided figure.

For specific applications, an axicon lens can be meticulously tailored with a designated axicon angle or base angle, finely tuned to meet the demands of the intended use. A prominent player in the field, Avantier specializes in the design and production of top-tier laser optic components and assemblies catering to a diverse array of laser systems. This extensive range encompasses CO2 lasers, high-power fiber lasers, solid-state lasers, laser diodes, and more.

Avantier excels in delivering laser lenses of superior performance, spanning wavelengths from ultraviolet to visible, near-infrared, and even extending to long-wave infrared. The lens substrates offered encompass a wide selection including BK7, H-K9L, Sapphire, UV-grade fused silica, IR-grade fused silica, calcium fluoride (CaF2), magnesium fluoride (MgF2), zinc selenide (ZnSe), zinc sulfide (ZnS), gallium arsenide (GaAs), germanium (Ge), and silicon (Si).

Please contact us if you’d like to schedule a free consultation or request for a quote on your next project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.