Right Angle Mirrors

Right angle mirrors, also known as turning mirrors, are specialized optical components with several unique characteristics and applications.

Design and Function

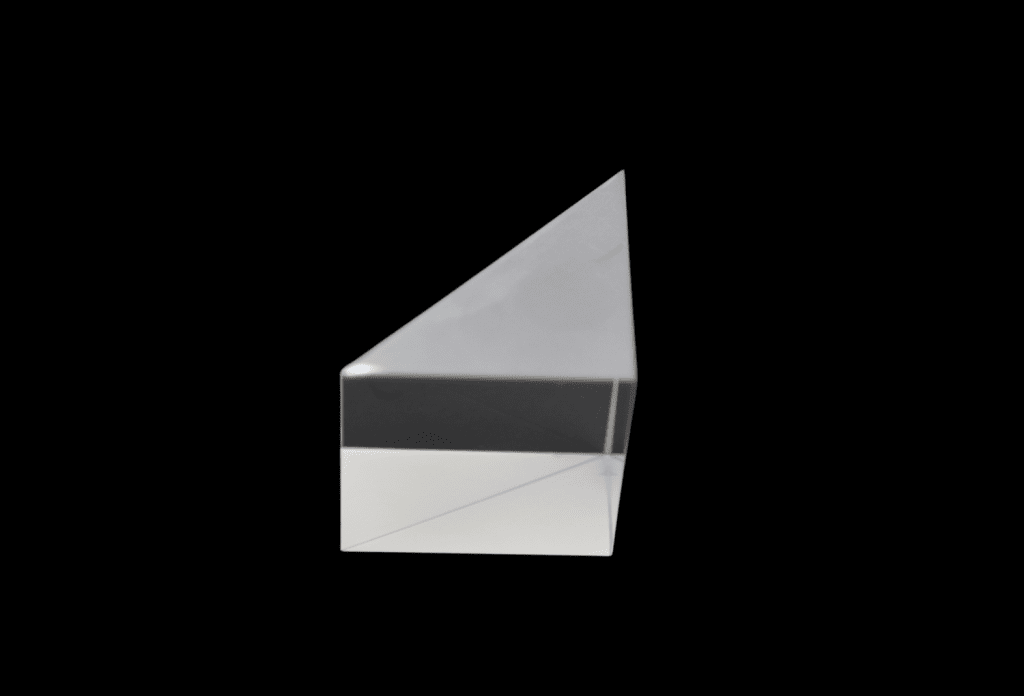

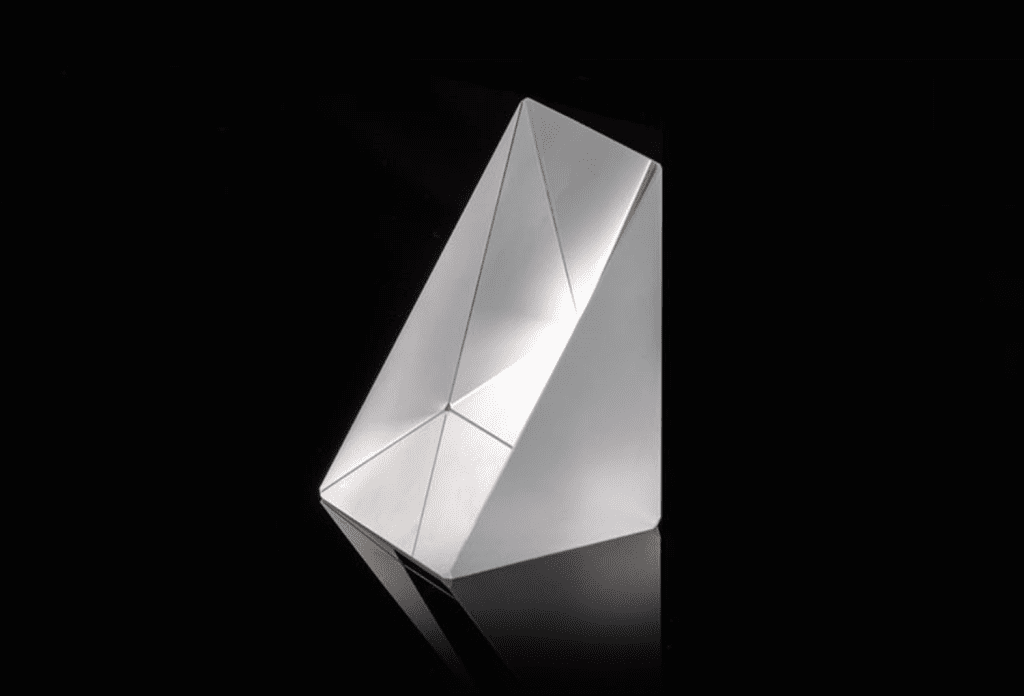

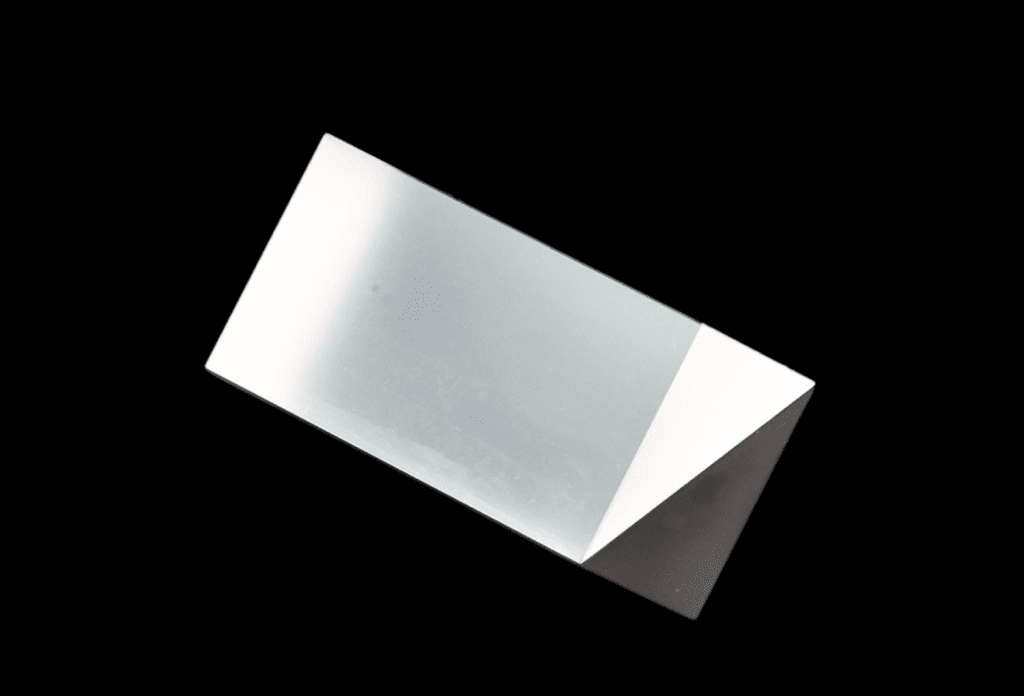

A right angle mirror is a triangular prism with a 90-degree angle between two of its faces. It serves the purpose of reflecting incident light at 90° angle, making it useful for changing the path of light in optical systems.

Incident light typically enters through one short leg of the prism, is reflected by the metallic coating on the hypotenuse (the 90° angle face), and exits through the other short leg.

Right angle mirrors are valued for their ability to efficiently redirect light at a right angle, making them suitable for various optical applications.

Substrate and Coatings

Right angle mirrors are commonly manufactured from BK7, a type of optical borosilicate-crown glass known for its optical quality and clarity.

The hypotenuse of the prism is coated with one of the following options:

- Enhanced Aluminum: This coating includes aluminum with a multilayer dielectric overcoat designed to optimize reflectance at specific wavelengths. It provides good reflection in the UV, visible, and mid-IR wavelengths.

- Protected Silver: Recommended for use with visible light.

- Protected Gold: Ideal for applications working with the full IR spectrum. Neither protected silver nor protected gold coatings are sensitive to the angle of incidence or polarization, making them versatile choices.

Applications

- Right-angle mirrors are known for their ease of alignment and can be easily mounted in optical systems.

- These mirrors are often employed in applications where precise alignment and high performance are critical.

- Right-angle mirrors are commonly used in compact optical waveguide devices and high-density integrated optics.

- They are also useful for reducing the size of optical systems by changing the path of light at a right angle.

Custom Right Angle Mirrors

Our experienced design team offers support for customers in designing their optical systems, from initial design to prototype development and production.

Customization options may include specific coating wavelengths or other requirements to meet the unique needs of customers’ applications.

Factory Standards

Spherical tolerance | λ/4 |

Diameter | +0, -0.2mm |

Surface quality | 40-20 |

Clear aperture | >90% |

Radius of curvature | +2% |

Bevel | 0.2mmx45°typical |

Thickness | >+0.2mm |

Material | BK7 |

Coating | Aluminum, gold, and silver (other coatings available on request) |

Our optical engineers are available to provide custom right angle mirror consulting and can help you design and produce a custom right angle mirror that best matches your application. Feel free to contact Avantier with a request for a quote or more information on custom options.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.