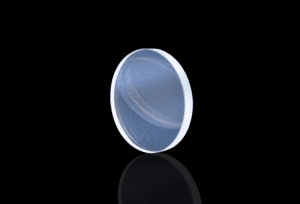

Fused Silica Windows

Fused silica windows stand out as a superior choice for exacting applications demanding precision and crystal-clear light transmission. These windows possess remarkable attributes such as minimal bulk scattering and autofluorescence, along with the option of exceptionally high surface quality and parallelism.

Optical windows, which are flat, transparent plates engineered to optimize light transmission, play a pivotal role in minimizing light reflection and absorption. They find widespread application in safeguarding electronic sensors and other optical systems from their surroundings. These windows can be employed to facilitate the passage of light into an instrument or to separate two enclosed spaces.

In a comparison with N-BK7, fused silica boasts superior characteristics including improved uniformity, a lower coefficient of thermal expansion, and reduced refractive index across various wavelengths. This renders it an ideal choice for applications requiring efficient transmission deep into the ultraviolet (UV) spectrum. Uncoated fused silica windows exhibit an approximate 4% loss per surface. Moreover, we offer anti-reflective (AR) coatings tailored to specific wavelengths, achieving an average reflection rate as low as 0.5%.

Substrate Options for Fused Silica Windows

Avantier provides fused silica windows with a diverse array of substrate options, including Corning 7980 fused silica, JGS1, JGS2, and Heraeus fused silica.

Corning 7980, characterized by high-purity non-crystalline silica glass, boasts minimal refractive index variations and exceptional transmittance spanning from deep ultraviolet to the infrared spectrum. Its homogeneity is certified for both on-axis (AA, A, C, F) and off-axis usage. At a wavelength of 589.3nm, it exhibits a refractive index of 1.45840, a density of 2.20 g/cm³, and a Knoop hardness of 522 kg/mm. Its tensile strength registers at 54 MPa at 25 degrees Celsius.

Heraeus fused silica offers various options suitable for UV, IR, Vis, or broadband spectrum applications. This non-crystalline isotropic glass adheres to the highest purity and substrate homogeneity standards.

JGS1, optimized for deep UV transmission, closely resembles Corning 7950 or Heraeus Suprasil 1 and 2. This synthetic amorphous silicon dioxide possesses no absorption bands in the 170-250 nm range but exhibits an intense OH absorption band between 2600-2800 nm. It is a premium glass with minimal bubbles or inclusions.

JGS2, tailored for light transmission spanning 220 to 2500 nm, enjoys widespread use in the solar industry and semiconductor applications. While it contains tiny bubbles, it has more than JGS1, and its OH content hovers around 120 ppm.

Avantier’s Fused Silica Windows

Avantier manufactures fused silica windows with diameters ranging from 3.5 to 25.4 mm and thicknesses spanning 1.0 to 3.0 mm. Our factory adheres to diameter tolerance standards of +0.0, -0.05mm and thickness tolerance of +/- 0.1mm. These windows consistently achieve a clear aperture exceeding 85 percent, and their parallelism consistently outperforms 5 arc minutes.

Wavefront distortion in our factory-standard windows is maintained at l/10 per 25mm. The surface quality is rated at 10-5 scratch-dig, meeting the rigorous demands of the most exacting laser applications. This figure is calibrated in accordance with U.S. Military Performance Specification MIL-PRF-13830B.

Material |

Corning 7980 fused silica, JGS1, JGS2,

|

Irregularity (fringe) |

l/10 |

Diameter Tolerance |

+0.0, -0.05mm |

Thickness Tolerance |

+/- 0.1mm |

Clear Aperture (%) |

>85% |

Parallelism |

5 arc min |

Surface Quality |

10-5 |

Wavefront Distortion |

l/10 per 25mm |

For further details on our manufacturing tolerances or to request custom sizes and specifications, please contact us if you’d like to schedule a consultation or request for a quote on your next project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.