Enhanced Precision in Optical Component Alignment

Motorized lenses are widely used in camera imaging systems for machine vision, robotics, video surveillance, and environmental detection applications. Avantier offers customized lens with motor controlled focus and shutter positions to meet customer’s unique requirements.

Highly Accurate Markings and Scales for Optical Component Alignment

In many applications, a special filter, polarizer, or cylindrical lens will need to be aligned and placed in the front of the lens or between the lens and camera sensor. The rotation angle accuracy of the optical components (such as lens array and polarizer) is critical and it can significant affect the system performance such as camera sensitivity, signal-to-noise ratio, etc. We can add markings and scales on the shell to show the mounting angle /rotation position of the mounting holders of the optical components such as filter, lens, polarizer, waveplate, etc. The high resolution markings can make the adjustment easily and precisely controlled. After alignment, Avantier uses setting screws and/or glue to prevent the movements of the mechanical parts that hold lenses, filters, mirrors, etc.

For some applications, it is not allowed to have (strong) light achieve the camera sensor/detector plane when the camera is not in working mode or camera is in the calibration process. Adding a light blocker in the front of the lens/camera is not realistic especially when the lens or camera is installed in an instrument or is mounted in the high position. Avantier can add a motorized shutter with simple On/Off operation feature to block the light without turning off the lamp or putting a cover in the front the lens/ camera.

Avantier also can add a focus motor on the lens for customers to control the lens focus position easily and precisely. The motor-controlled lens can move the entire lens with high repeatability. Stepper motor and gearhead with zero backlash can be selected based on customer needs. Visible markings/scales can also be added on the lens shell to indicate the lens focus positions.

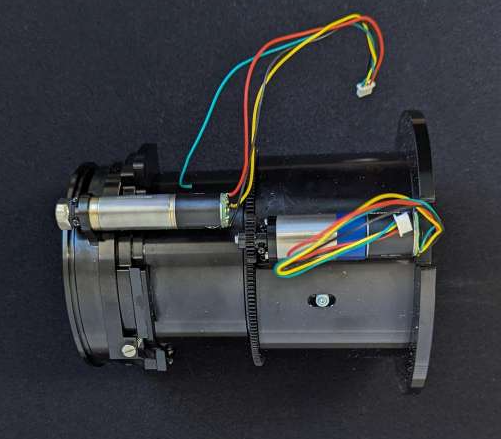

A picture below shows an example of Avantier’s motorized lens products. The lens is equipped with two stepper motors. One (i.e. the top motor) is used to control the shutter position, and another one (i.e., the bottom motor) is used to control the lens focus position. The white markings/scale is used to indicate the polarizer/filter rotation angle position. The screw hole (i.e. red circle in the picture) is specially used for installing screws to lock the polarizer mount position after alignment is finished. The positions of all the optical components are secured for this lens.

Avantier offers both manual focus/ iris lenses and motorized lenses. In this era of exacting standards, Avantier’s commitment to excellence shines through in every product. With motorized lenses that secure the positions of optical components, Avantier equips professionals across machine vision, robotics, surveillance, and environmental detection with the tools they need for uncompromised performance and accuracy. Please contact us if you’d like to schedule a consultation or request for a quote on your next project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.