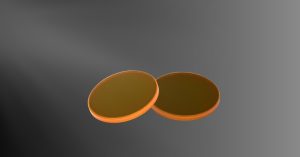

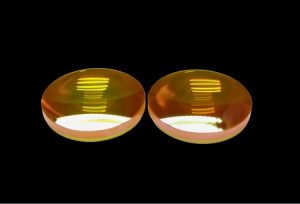

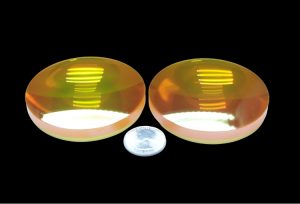

ZnSe Lens

Crafting Excellence in ZnSe Lenses for Cutting-Edge Applications

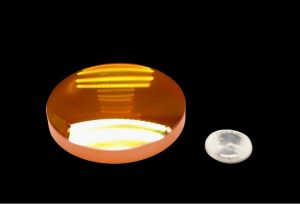

Avantier specializes in the custom manufacturing of high-quality Zinc Selenide (ZnSe) lenses, catering to diverse specifications and sizes. These precision optics find common applications in thermal imaging, high-power CO2 laser systems, and life sciences.

ZnSe, a transparent polycrystalline substance with a yellowish tint, exhibits transmission in the 0.5-21µm range, making it well-suited for mid-infrared applications. Avantier’s ZnSe lenses maintain less than 0.3 percent total absorption at infrared wavelengths, contributing to energy efficiency and increased accuracy in sensitive instrumentation, particularly in laser optics.

The material’s properties include a low absorption coefficient (0.0005 cm-1 at 10.6 μm), a melting point of 1525°C, and a thermal conductivity of 18 W m-1 K-1 at 298K. ZnSe lenses demonstrate high resistance to thermal shock, making them suitable for thermally demanding applications.

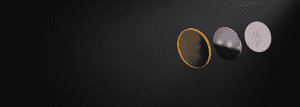

Reflectivity of ZnSe is typically 29.1% at 10.6 μm (2 surfaces), and Avantier offers anti-reflective coatings to minimize energy loss. Given the material’s susceptibility to scratching, careful handling is recommended.

Avantier employs chemically vapor deposited ZnSe blanks for crafting precision lenses. The production process involves cutting blanks to size, diamond turning for precise curvature, and polishing to high standards. Lenses are rigorously tested using state-of-the-art metrology equipment to ensure accuracy and performance.

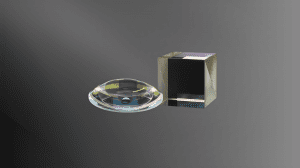

The product range at Avantier includes spherical, cylindrical, meniscus, aspherical, plano-concave, concave-convex, and plano-convex lenses in various diameters, thicknesses, focal lengths, and configurations. While lenses for CO2 laser focusing applications are supplied without coatings for high performance, anti-reflection and other optical coatings can be applied as needed.

Avantier offers custom ZnSe lens design consulting to assist customers in selecting the most suitable lens for their applications. The commitment to quality ensures the production of top-tier ZnSe lenses at competitive prices.

Factory Standard

Substrate Material | ZnSe |

Shape | Spherical Plano-Concave, P-Convex, Concave-Convex or Aspheric |

Surface Figure | λ/20 before coating at 10.6μm |

Surface Quality | 40-20 per MIL-PRF-13830B |

Dimensional Tolerance | + 0.00mm, – 0.25mm |

Thickness Tolerance | +/- 0.25mm |

Chamfer | 0.35mm at 45° (typical) |

Concentricity | < 0.05mm |

Focal Length Tolerance | +/- 2% |

Antireflection Coating | Ravg < 0.6% per surface at 3-5μmRavg < 0.75% per surface at 8-12μmRavg < 0.5% per surface at 10.6μm |

Clear Aperture | > 85% |

Absorption | <0.3% total absorption as measured by CO2 laser calorimetry |

Design Wavelength | 10.6μm |

Custom ZnSe Lenses

If you have more questions about custom ZnSe lenses and manufacturing services, don’t hesitate to contact us. Our experienced optical designers are always available to discuss a custom order.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.