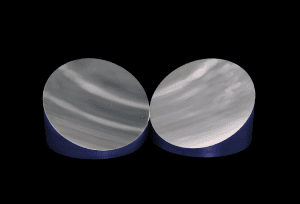

Metallic Mirrors

Metallic mirrors are metal coated optical mirrors that provide broadband reflections and low chromatic dispersion. At Avantier, we produce custom metallic mirrors for LWIR lasers, infrared optics and other broadband applications.

Applications of Metallic Mirrors

Metallic mirrors are important in spectroscopy and infrared optics. The exact mirror chosen will depend on the application; for instance, gold coatings have very high reflectance in the infrared region, for 600 nm and above. Silver has good reflectance in the visible range, from 500 nm to μm. More economical aluminum mirrors can be used with light of wavelengths from 300 nm on through IR. Aluminum mirrors do have a lower damage threshold than silver and gold and so are less ideal for laser applications.

Gold-coated mirrors are highly desirable for CO2 experiments, and silver-coated mirrors are a good choice for use with femtosecond Ti: Sapphire lasers.

Types of Metallic Mirrors

Metallic mirrors can be divided into two types: first surface mirrors and second surface mirrors.

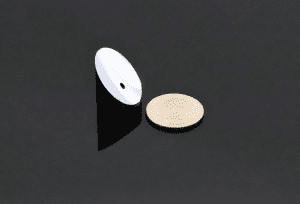

In a first surface mirror, the side of the mirror which faces the incident light is metal coated. For a first surface mirror light will not reach the substrate; it will barely penetrate the coating and be reflected. These mirrors often have an extra enhancement coating over the metallic coating for protection and better optical qualities; for instance, SiO2 (silica) or Si3N4 (silicon nitride) are often used to protect delicate metal surfaces from oxidation and from scratching. Protected aluminum, protected silver, enhanced silver and protected gold are some examples of coated mirrors.

In a second surface mirror, the metallic coating is on the side away from incident light. Light travels through the substrate before reaching the metal and being reflected back. The benefit of these mirrors is that the coating is protected by the substrate, and a protective paint can be used on the outer surface of the coating for extra protection. The downside of this type of mirror is potential chromatic dispersion in the glass, or a Fresnel reflection at the first surface causing ghost images.

The substrate in a first surface mirror might be optical glass but could also be a nontransparent material like aluminum. The substrate in a second surface mirror, however, should be transparent to light in the target wavelengths.

Factory Standards

Surface Flatness | λ/4 |

Diameter | +0, -0.2mm |

Surface Quality | 40-20 |

Parallelism | 90% diameter |

Bevel | 0.2mmx45° typical |

Laser Damage Threshold | 0.4J/cm2 for 532nm @10ns pulse (measured) |

Durability | to MIl-C-675 |

Reflectance | R>88% (350-2000nm) |

Metallic Mirrors at Avantier

At Avantier, we produce custom metallic mirrors for our customers in research, medicine, industry and defense. Our skilled design and engineering teams are able to work with you to determine the ideal design for your application, and we have the manufacturing ability to produce whatever metallic mirror you might need. State of the art metrology equipment enables us to ensure your mirror meets and exceeds all applicable standards.

Don’t be satisfied with in-stock metallic mirrors that only approximately meet your needs. Get a mirror made to order for your application, and experience the precision results you get when using optical parts tailored to your exact needs.

Call us today to place a custom order or to schedule an introductory consult.

Related Content:

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.