Dichroic Mirrors

A dichroic mirror, also known as a dual-band mirror, dual-wavelength mirror, or dichroic reflector, is an advanced optical component that exhibits distinct optical properties at two different wavelengths. It plays a pivotal role in various optical devices by enabling the separation of light based on its wavelength. At Avantier, we specialize in manufacturing top-tier custom dichroic mirrors that meet the highest standards of quality and precision.

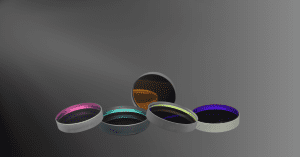

Types of Dichroic Mirrors – Tailored for Diverse Applications

Dichroic mirrors encompass different transmission characteristics, allowing for versatile applications. The main types include longpass, shortpass, and multi-band dichroic mirrors. Additionally, they used to suppress unwanted heat in thermally sensitive applications are categorized as hot and cold mirrors.

Longpass dichroic mirrors are designed with a cut-on wavelength that effectively separates a highly reflective band from a transmissive band. As a result, longer wavelengths beyond the cut-on point easily pass through the mirror, while shorter wavelengths are reflected back.

Conversely, shortpass dichroic mirrors feature a cut-off wavelength. In this case, radiation above the cut-off wavelength experiences high reflectance, while radiation below it is efficiently transmitted.

Multi-band dichroic mirrors exhibit more complex transmission characteristics, with both cut-off and cut-on wavelengths. They offer two transmission bands and one reflective band. The region between the cut-off and cut-on wavelengths provides high reflectance, while wavelengths above the cut-on and below the cut-off are predominantly transmitted.

Precision Manufacturing Techniques for Unparalleled Quality

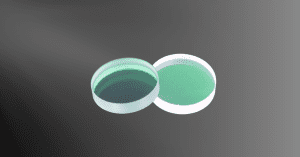

Most dichroic mirrors fall into the category of dielectric mirrors, constructed using multiple layers with varying optical properties. At Avantier, we employ cutting-edge deposition techniques such as electron beam deposition, ion beam sputtering (IBS), and ion-assisted deposition (IAD) to manufacture these high-performance mirrors. Our state-of-the-art thin film deposition processes ensure that each mirror produced in our factory adheres to exact specifications for its intended application.

The hard dielectric coatings applied to our dichroic mirrors make them remarkably durable while maintaining their ease of handling, similar to glass. They exhibit exceptional thermal stability under normal conditions, making them suitable for use even with high-power lasers.

The reflectance spectrum of a dichroic mirror is influenced by the angle of incidence of the light. Our mirrors are typically designed for use at a 45-degree angle of incidence. However, if your application requires a different angle, we welcome you to contact us to discuss the possibility of manufacturing a custom mirror tailored to your specific requirements.

Unlocking Applications Across Industries

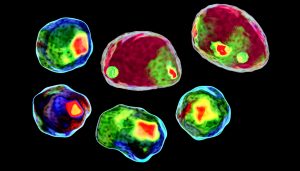

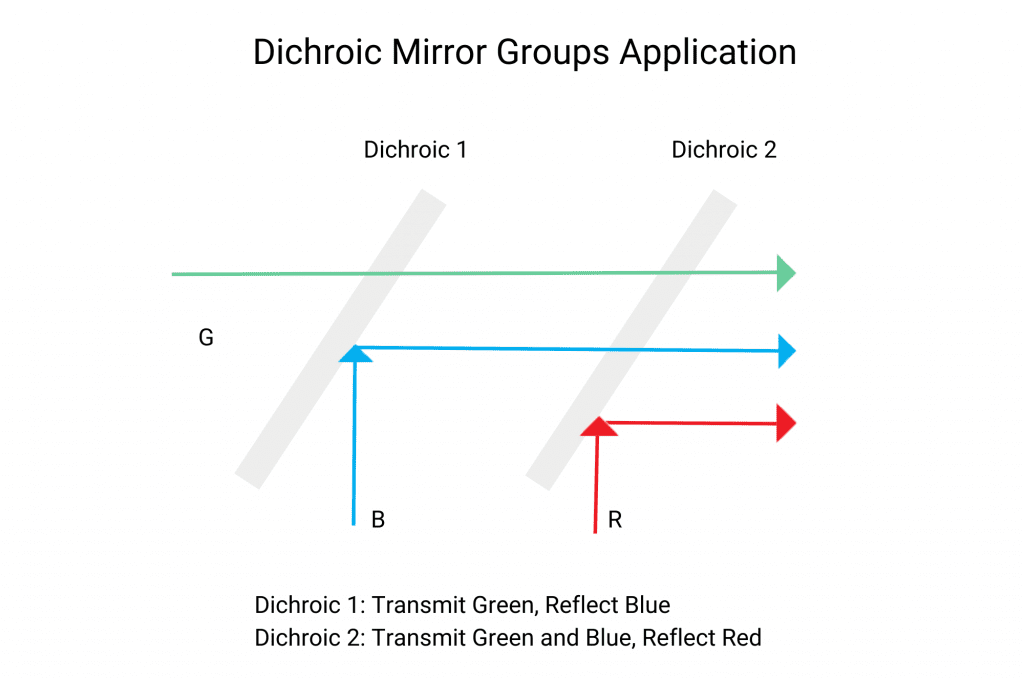

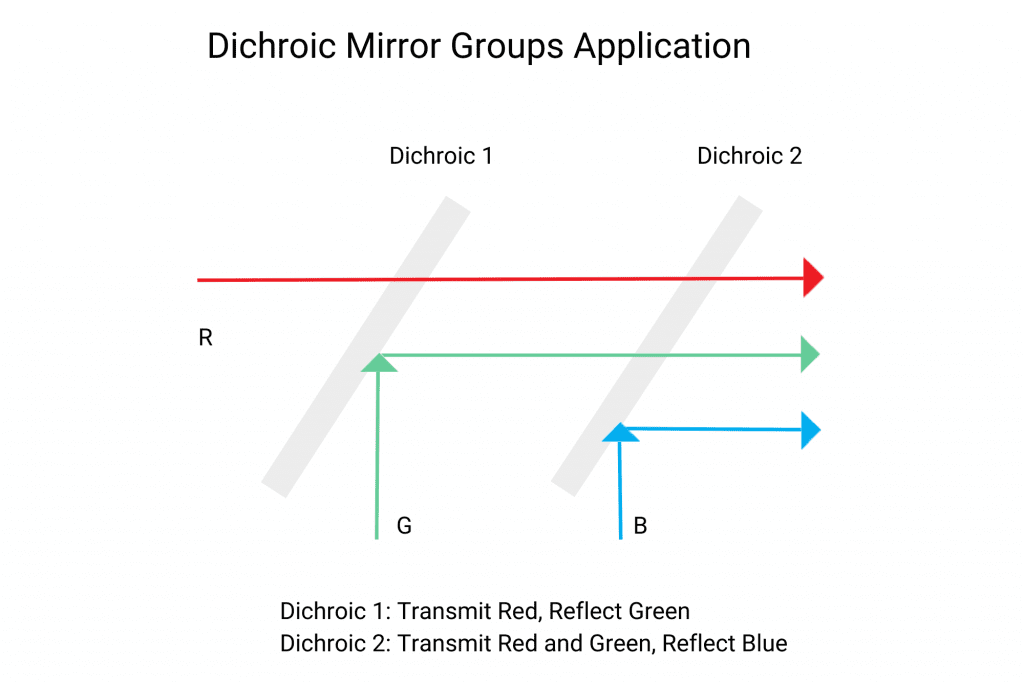

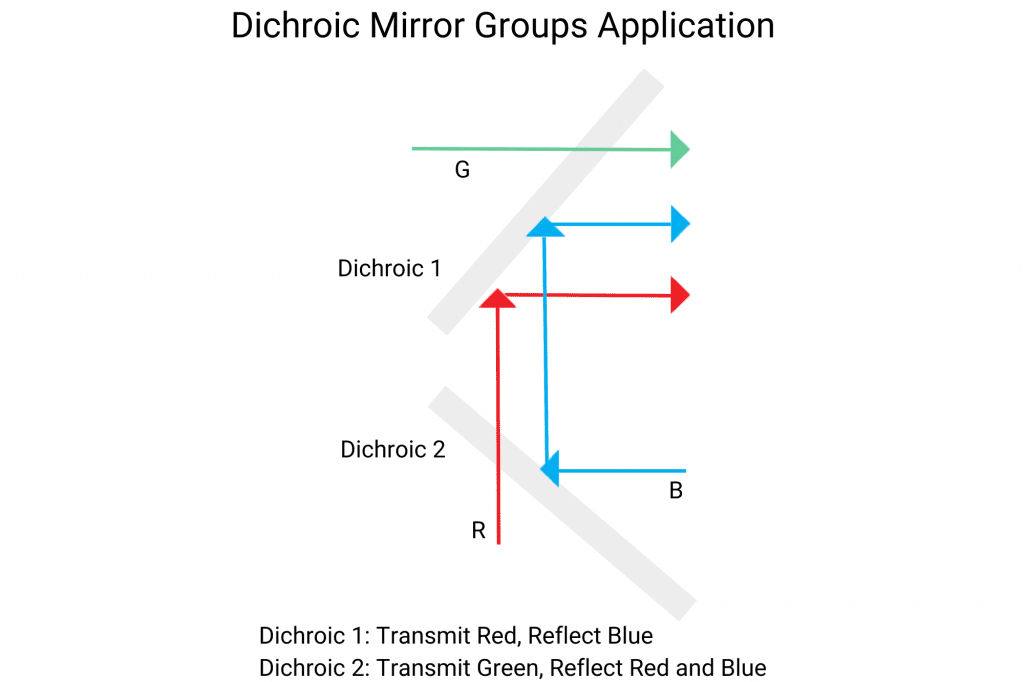

Dichroic mirrors find essential applications in filtering spectral components, splitting or combining beams with different wavelengths, and fluorescence microscopy. Unlike ordinary beam splitters, dichroic mirrors enable wavelength separation without significant intensity loss, making them highly versatile and valuable across various fields.

For instance, in fluorescence microscopy, dichroic mirrors are instrumental in separating the fluorescence light, which carries critical image information, from the residual pump light, enhancing the overall imaging performance.

Custom Dichroic Mirrors

At Avantier, we specialize in manufacturing custom dichroic mirrors precisely tailored to your specifications. We encourage you to reach out to us to discuss your specific requirements and explore how our expertise can contribute to your project’s success.

Factory Standards:

Material | UV grade fused silica or BK7 glass |

Diameter Tolerance | +0.00 mm to -0.12 mm |

Thickness Tolerance | ±0.25 |

Parallelism | 30 arcsec |

Chamfer | 0.3 mm at 45° (typical) |

S1 Surface Flatness | λ/10 (typical at 633 nm) |

S1 Surface Quality | 20-10 scratch & dig |

S2 Surface Flatness | λ/10 (typical at 633 nm) |

S2 Surface Quality | 20-10 scratch & dig |

Coating Specifications:

- Technology: Electron beam multilayer dielectric

- Adhesion and Durability: Compliant with MIL-C-675A, insoluble in lab solvents

- Clear Aperture: Exceeds central 85% of diameter

- Laser damage threshold

- BK7: > 2 J/cm², 8 ns pulse, 1064 nm

- UV FS: > 5 J/cm², 8 ns pulse, 1064 nm

- Coated Surface Flatness: λ/10 at 633 nm over 85% of diameter

- Angle of Incidence: Designed for 45 degrees

- Back side antireflection coated: Reflectance less than 0.5%

Contact us today to benefit from our expertise and discuss your project.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.