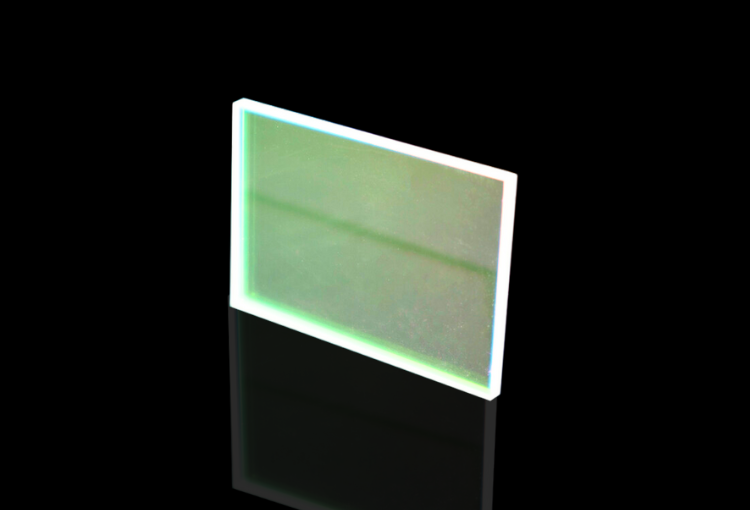

Fused Quartz Windows

Fused quartz windows are prized for their exceptional optical clarity, minimal thermal expansion, and remarkable light transmission, boasting an impressive 80% or greater efficiency across a broad wavelength spectrum spanning from 260nm to 2500nm. Distinguished by its superior hardness when compared to standard glass, fused quartz can withstand extreme temperatures, enduring conditions as demanding as 1050°C. These windows find widespread utility in scientific research, as well as various commercial and industrial settings, owing to their remarkable attributes, including exceptional durability, robust resistance to chemical agents, outstanding thermal stability, and affordability. Avantier specializes in the customization of fused quartz windows, accommodating varying diameters and thicknesses to suit precise application requirements.

Key Features

- Optical Excellence: Fused quartz windows deliver exceptional optical quality, making them ideal for applications where clarity and precision are paramount, such as in spectroscopy and laser systems.

- Low Thermal Expansion: With a minimal coefficient of thermal expansion, fused quartz windows remain dimensionally stable even when exposed to extreme temperature fluctuations, ensuring consistent performance.

- Broad Wavelength Range: These windows offer high light transmission efficiency across a wide wavelength range, enabling their use in diverse applications, including ultraviolet (UV) and infrared (IR) spectroscopy.

- High Temperature Tolerance: Fused quartz windows can withstand temperatures of up to 1050°C, making them suitable for use in high-temperature processes and environments.

- Chemical Resistance: Their resistance to corrosive chemicals makes fused quartz windows indispensable in laboratories, chemical processing, and industrial environments where exposure to harsh substances is common.

- Thermal Stability: Fused quartz exhibits exceptional thermal stability, ensuring that the optical properties of the window remain consistent under varying temperature conditions.

- Cost-Effective: Fused quartz windows offer an economical solution for applications requiring high-quality optics and durability, making them a preferred choice in various industries.

- Customization: Avantier provides the flexibility to customize fused quartz windows, allowing for the creation of windows with specific diameters and thicknesses tailored to unique project requirements.

Applications

- Scientific Research: Fused quartz windows are indispensable in laboratories and research facilities for their optical clarity and suitability for a wide range of experiments, including spectroscopy, microscopy, and laser-based studies.

- Industrial Processing: They are used in industrial settings, such as semiconductor manufacturing and chemical processing, where their resistance to high temperatures and corrosive chemicals is crucial.

- Optical Systems: Fused quartz windows are integral components in optical systems, including telescopes, cameras, and imaging devices, where their optical quality and thermal stability enhance overall performance.

- UV and IR Applications: Their excellent transmission properties in the UV and IR spectra make fused quartz windows invaluable in applications like UV spectroscopy, infrared imaging, and photolithography.

- High-Temperature Environments: Fused quartz windows find use in furnaces, ovens, and aerospace applications where they can endure extreme temperatures while maintaining optical integrity.

- Chemical Analysis: They are utilized in analytical instruments, such as mass spectrometers and gas chromatographs, for their ability to resist chemical degradation during sample analysis.

Fused quartz windows offer a unique combination of optical quality, durability, and versatility, making them essential components in a wide array of scientific, industrial, and optical applications. Their ability to maintain optical performance in demanding conditions positions them as valuable assets across various industries.

Factory Standard

Dimensions: | 1mm to 500mm/Commercial grade up to 1300mm x 1300mm |

Thickness Range: | 0.1mm to 50mm (subject to dimension) |

Dimension/Thickness: | Tolerance up to 0.02mm |

Edge Finish: | Ground or polished |

Surface Quality: | 80/50 to 10/5 scratch/dig |

Surface Flatness: | Up to lambda 10 (@633nm) |

Parallelism: | Up to 5 seconds |

Material Options: | Commercial Grade Quartz, Heraeus Herasil, GE124, OHARA SK1300, and Corning 7980 |

Coating Options: | AR coatings, Silver coating, Gold coating, etc |

Options: | Edges polished, wedges, shapes, drilled holes & beveled angles |

Contact us today to discuss your optical needs and find the perfect window for your requirements.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.