Powell Lens

A Powell lens is a laser line generator and can be used to convert laser beams into uniform straight laser lines, fanning out collimated beams in one dimension. At Avantier, we produce custom Powell lenses for a wide variety of clients.

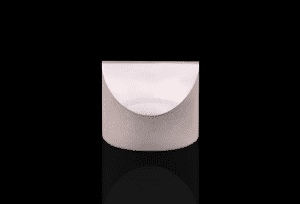

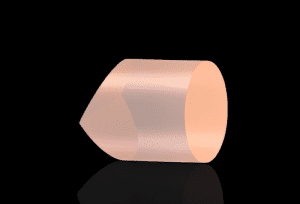

Anatomy of a Powell Lens

A Powell lens is a prism with a rounded roof, and it is that rounded roof which makes it so incredibly useful as a laser line generator. When a collimated laser beam is passed through cylindrical lenses, the result is a poorly illuminated, non uniform Gaussian laser beam; a line with faint edges and a hot spot in the center.

The two-dimensional aspheric curve of the Powell lens roof introduces a spherical aberration into the optical system; an aberration that decreases the light in the central area while increasing the light intensity at the edge of the resulting beam.

Each Powell lens has a specific fan angle. This angle tells you how wide an angle the original beam is fanned out over. It is fully determined by the roof angle of the Powell lens and the index of refraction of the substrate. The performance of these lenses is sensitive to the laser beam width, and for ideal results you will want to use a Powell lens with a roof curvature designed for your specific laser width.

Powell Lenses

Applications of Powell Lens

Powell lenses are used in all manner of machine vision applications, as well as laser cutting, welding, and drilling. They are important in industry, research, medicine, and defense. They are the most powerful solution currently available for applications where a uniform, straight laser beam is required, and are also flexible and relatively cost-efficient.

For example, a Powell lens can be used to improve the performance of a laser scanning and imaging system. It can be used to reduce the cost of laser shaping apparatus, as one piece does the work that would otherwise be done by a complicated assembly. It can also be used to enable the precise laser beam control needed in scientific research applications, or to improve the accuracy of laser measurement systems.

Factory Standard – Powell Lenses

Material | N-BK7, N-SF57, N-SF2 |

Diameter | 9mm |

Diameter Tolerance | +0.00/-0.06mm |

Fan Angle | 10°, 20°, 30°, 35°, 45°, 54°, 55°, 70°, 75°, 80°, 90°, 110° |

Fan Angle Tolerance | +/- 1° |

Wavelength Range (nm) | 405 -808 |

Input Beam diameter (mm) | 0.5, 0.8, 1, 2, 4, 5, or other |

Surface Irregularity | λ/4@632nm |

Surface Quality (Scratch-Dig) | 80-50, 60-40 |

Line Uniformity | 10% variation over central 80% of line at 632nm |

Line Straightness | 0.1% over central 80% of line at 632nm |

AR Coating Range | Upon customer’s request |

Custom Powell Lenses at Avantier

At Avantier, we specialize in custom Powell lenses designed to precisely match our client’s specifications. While these lenses are both powerful and flexible, they must be manufactured to a high standard, as both the straightness and aperture deviation of the resulting line depends on the quality of the prism. The Powell lens must also be designed with an apex angle that matches the laser line width of the application. The design and engineering staff at Avantier can help you determine the exact parameters needed for your application, and our state of the art manufacturing and metrology equipment enable us to produce the exact part you need to the highest standard. Don’t be satisfied by something that almost works. Contact us today to set up an initial consult, and get started on your own custom order.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.