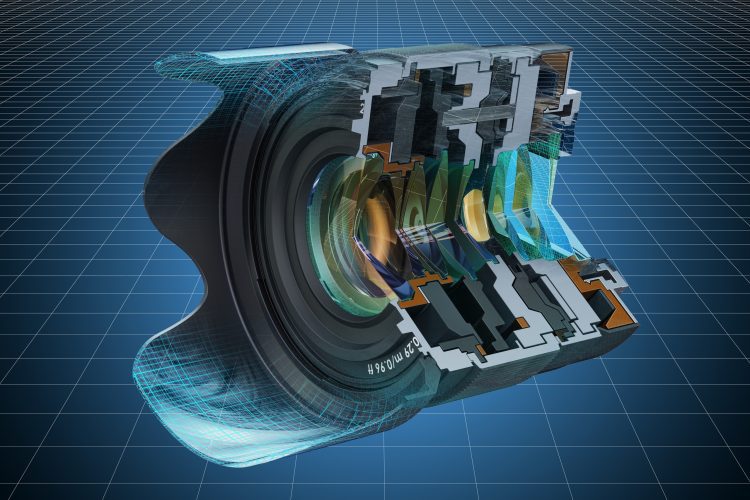

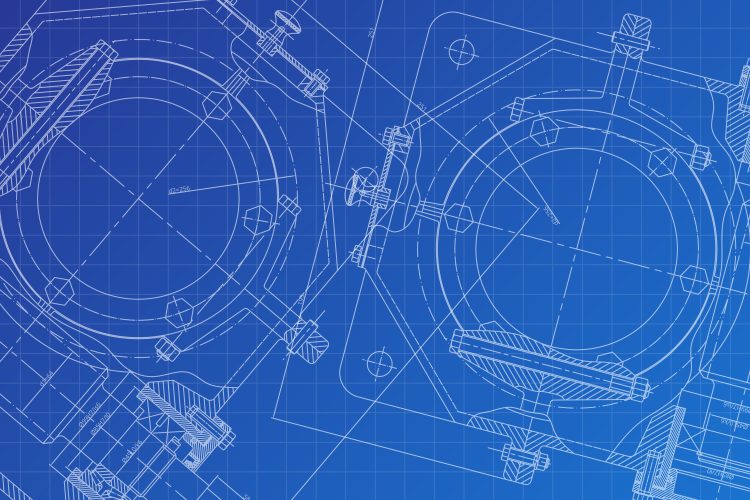

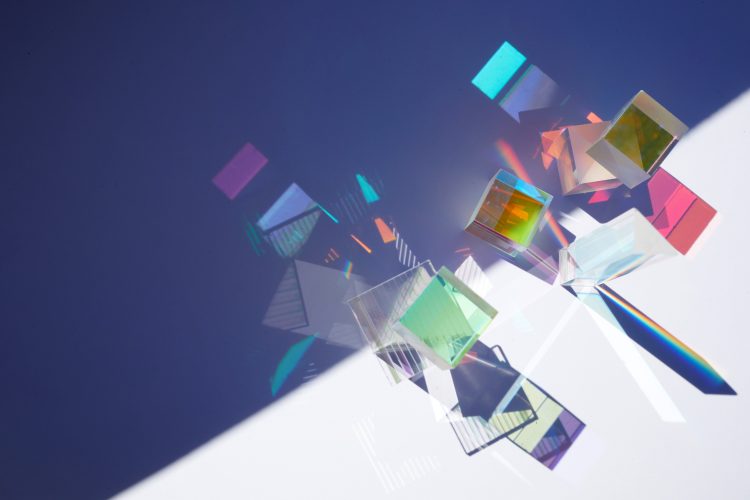

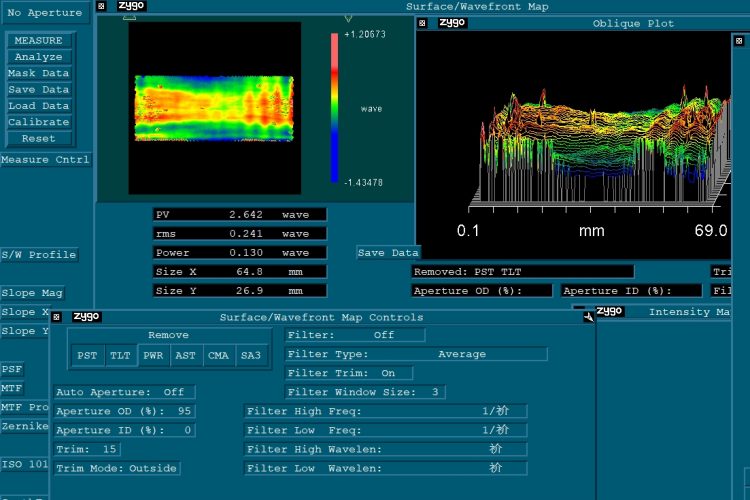

Optical design refers to the design process of optical components and optical systems using optical principles and technologies. Optical design has a long history, and in recent years, due to the development of design software, optical design work has become simpler and more practical.