Chalcogenide Optics for Infrared Imaging and Athermal Lens Design

Chalcogenide optics are specialized infrared optical components made from chalcogenide glass—a group of materials containing sulfur, selenium, and/or tellurium, often combined with germanium or arsenic. These materials are ideal for use in infrared (IR) systems due to their excellent transmission in the mid-wave IR (MWIR, 3–5 µm) and long-wave IR (LWIR, 8–12 µm) wavelength ranges.

At Avantier, we offer custom chalcogenide optics for advanced thermal imaging, infrared sensing, and photonic applications. We specialize in precision molded chalcogenide lenses, supporting both high-volume production and prototype development.

Key Benefits of Chalcogenide Optics

Broad Infrared Transmission

Chalcogenide glass transmits IR light effectively from 3 µm up to 12–15 µm, making it ideal for thermal cameras, infrared spectroscopy, and multispectral imaging systems.

High Refractive Index

With refractive indices ranging from 2.3 to 3.0, chalcogenide lenses enable compact, high performance IR optical systems. This makes them suitable for use in space-constrained environments such as drones, wearable IR devices, and handheld thermal cameras.

Low Thermal Sensitivity (Athermalization)

Chalcogenide glass features a low dn/dT (refractive index temperature coefficient) and minimal thermal expansion, enabling passive athermalization in optical designs. This ensures stable focusing performance across wide temperature ranges—essential for outdoor and defense IR systems.

High Optical Nonlinearity

These glasses offer strong third-order nonlinearity, making them suitable for nonlinear optical devices, mid-IR lasers, and photonic integrated circuits (PICs).

Machinability and Molding Compatibility

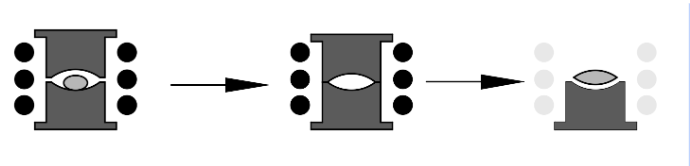

Chalcogenide materials are softer than crystalline IR optics (Mohs 2–3), allowing precise fabrication via:

- Traditional polishing and diamond turning

- Precision glass molding (PGM) for volume manufacturing

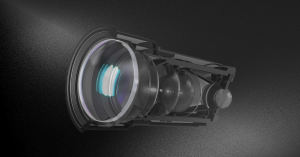

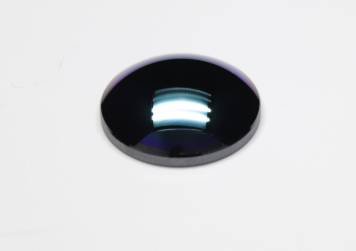

Precision Molded Chalcogenide Lenses

Avantier manufactures precision molded chalcogenide optics, ideal for high-volume applications. Using state-of-the-art molding techniques, we produce lenses with complex shapes, including aspheric IR lenses, without the need for post-processing like grinding and polishing.

Advantages of Precision Glass Molding (PGM)

- Cost-effective for medium to high production volumes

- Excellent shape accuracy and surface quality

- Scalable production with minimal variability

- Suitable for ruggedized IR lens assemblies

Note: Chalcogenide glass is moldable, unlike germanium or zinc selenide, offering a key manufacturing advantage for complex infrared lens designs.

Applications of Chalcogenide Optics

Our custom chalcogenide lenses and windows serve a wide range of IR and photonics markets, including:- Thermal Imaging Cameras (LWIR & MWIR)

- Athermalized IR Lens Assemblies

- Night Vision and Surveillance Systems

- Autonomous Vehicle IR Sensors

- Spectroscopic Instruments

- Infrared Windows and Domes

- Photonic Integrated Circuits (PICs)

- Mid-IR Laser Optics and Beam Shapers

Chalcogenide Optics vs Germanium Optics

Property | Chalcogenide Glass | Germanium |

IR Transmission | 3–12+ µm | 2–14 µm |

Moldability | Yes (PGM-compatible) | No |

Cost | Lower | Higher |

Weight | Lighter | Heavier |

dn/dT | Lower (Better for athermalization) | Higher |

Chalcogenide lenses are a cost-effective alternative to germanium optics, especially when moldability and weight are critical factors.

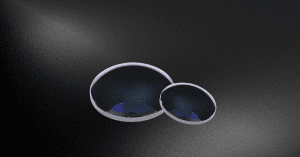

Custom Chalcogenide Optical Components

Avantier offers custom-designed chalcogenide IR optics to meet your exact specifications. Our capabilities include:- Spherical and aspheric chalcogenide lenses

- Optical windows and domes

- Lens arrays and beam shaping optics

- Anti-reflective and DLC coatings for durability

Work With an Expert in Infrared Optics

With decades of experience in infrared lens design, precision molding, and custom optical fabrication, Avantier is your trusted partner for advanced chalcogenide optical components. Whether you need high-resolution IR lenses or ruggedized optics for harsh environments, we can deliver optimized solutions on time and to spec.

Get in touch today to discuss your chalcogenide optics needs or request a quote for your IR system.

WE CAN HELP YOU!

Contact us NOW for sales & expert advice.