Key Takeaways

- Optical Design for Manufacturing optimizes your optical component and optical assembly designs for improved quality and cost-effectiveness.

- Standardization and design simplicity help reduce production time and lower manufacturing costs.

- Streamlining assembly minimizes complexity, ensuring efficient and accurate manufacturing.

- DFM benefits customers by providing faster, more efficient production with higher quality outcomes.

Optimizing Optical Designs for Efficient Manufacturing and Superior Quality

Optical design for manufacturing involves optimizing your designs right from the blueprint stage. It takes into account not only the specific requirements for a design, as determined by the application, but also optimal manufacturing processes that will result in the highest quality optical component.

Design for manufacturing (DFM) results in streamlined, ready-to-implement designs and has the potential to shorten optical product development cycles. It also lowers cost, even while improving quality. When you’re looking at custom optics, it’s something you never want to do without.

Basics of Optical Design for Manufacturing

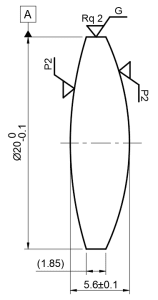

Some basic principles of DFM for optical systems and components include standardization, design simplicity, and streamlined assembly. Standardization in DFM involves using standardized components, materials, and processes where possible, but it doesn’t mean putting a round peg in a square hole. At Avantier, we’re all about in producing custom-made optics built for you. At the same time, we recognize that when a standard-size lens can be used instead of a unique one, you might save a significant amount of money, get your parts that much quicker, and end up with just what you need. That’s how standardization in design for manufacturing and optical engineering works— determining where and how standardized components or processes can be used to create a custom product that does exactly what you want it to.

Simplifying designs involves eliminating unnecessary components. Sometimes one optical component can perform two functions instead of one, and when that happens, we are not only able to cut the cost and manufacturing time but also the size and weight of the finished product.

Streamlining Assembly means paying attention to exactly how every optical component will fit together, minimizing the number and complexity of operations in manufacturing assembly, and ensuring that the tolerances of each individual part add up just the way they should.

Materials chosen are another important aspect of design for manufacturing. We can source almost any optical material one might want to use, but some materials are considerably more expensive than others. Some materials come in easy-to-use sizes, while others are only available in large, unwieldy blanks. Applying DFM to material choices means taking all of these issues into account even while selecting the best materials for a particular design.

Frequently Asked Questions

At what point in the process does design for manufacturing take place?

Ideally, design for manufacturing starts at phase 0— the very beginning of the design process. When Avantier’s experienced optical designers take on a new project, they bring in an extensive knowledge of manufacturing. This helps them to ensure that designs are optimized both for manufacturing and for your specific application.

But design for manufacturing doesn’t stop there. It’s a continuous improvement mechanism that keeps working throughout the whole design and prototyping process to refine your optical design and ensure it is the best it can be

What are the benefits of optical design for manufacturing?

You’ll see a wide range of benefits when you begin to take advantage of design for manufacturing. A few of the benefits include:

- Lower cost

- Faster production

- Higher efficiency

- Less waste

- Higher performing assemblies

- Better scalability

Optical design for manufacturing is especially important when you need to manufacture high quality parts in volume. One good example is disposable medical optics: lives depend on the high performance of many types of medical device, so quality is key, but costs must also be kept down and production must take place within a very limited time frame. That said, DFM can still be extremely useful even for situations where you might have a higher budget and need only a single optical assembly. A simplified, streamlined design can help to simplify your workload as well.

Who really benefits from design for manufacturing? Isn’t the manufacturer?

Does design for manufacturing just benefit the manufacturer? This is a common misunderstanding, but as it turns out, it’s you who benefits! At Avantier, we aren’t gaining any benefit from the lower cost and quicker processing time of each of our optimized products— you do. Every bit of monetary and time savings is passed on to our valued customers, who also end up with a higher quality, more efficient product.

Can I apply design for manufacturing to an existing optical design?

Yes! If you’ve got an optical blueprint or prototype that hasn’t been designed for manufacturing, we can work with you to refine your design so that it is cheaper and faster to manufacture— and ensure that your new design functions just as well, or even better.

I’d like to get an optical assembly designed for manufacturing. How do I start?

Give us a call, or drop a note in our contact form! Our optical design and engineering teams are ready to help you make your ideas reality.

GREAT ARTICLE!

Share this article to gain insights from your connections!