Key Takeaways

- Optical Coherence Tomography (OCT) relies fundamentally on High-Precision Optics for its unparalleled imaging capabilities.

- Key OCT System Optical Components, like OCT Scan Lenses, OCT Beam Splitters, and OCT Collimators, must meet strict tolerances for wavefront quality and dispersion.

- Achieving superior image contrast and resolution hinges on minimizing aberrations.

- Manufacturing these components presents challenges in surface quality, broadband dispersion control, and miniaturization, demanding advanced techniques to ensure micron-scale resolution & low-noise OCT.

Optical Coherence Tomography (OCT) has emerged as a powerful, non-invasive imaging technique that delivers real-time cross-sectional views of biological tissues with micrometer-scale resolution. The ability of OCT to reveal structural details beneath the surface of tissues—without physical contact—relies heavily on the quality and precision of its optical components.

From broadband light sources to interference optics and scanning mechanisms, each component in an OCT system must meet strict tolerances for wavefront quality, alignment, and dispersion control. This article explores the role of high-precision optics in OCT systems, covering technical principles, key optical elements, manufacturing challenges, and practical solutions.

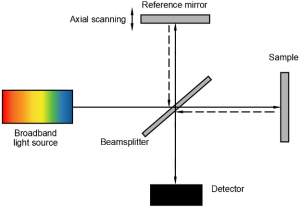

OCT Imaging Principles and Optical Requirements

OCT is based on low-coherence interferometry, where light reflected from internal microstructures is compared to a reference arm. This technique provides depth-resolved imaging with axial resolutions typically ranging from 1 to 15 µm.

Key Optical Requirements:

Parameter | Typical Value | Optical Impact |

|---|---|---|

Axial resolution | 1–15 µm | Requires broadband, low-coherence light |

Lateral resolution | 5–25 µm | Dictated by focusing optics NA and aberration |

Optical path length diff. | <1 µm across the system | Requires wavefront-optimized optics |

Chromatic dispersion | Minimized or balanced between arms | Requires careful material and design selection |

Key High-Precision Optical Components in OCT

- Collimators and Beam Expanders

- Must maintain low divergence (<1 mrad) and near-diffraction-limited quality.

- Typically built from aspheric doublets or molded glass optics to reduce spherical aberration.

- Materials used: fused silica, N-SF11, N-BK7, or IR-transparent glasses (for 1.3 µm OCT).

- Scanning Optics (Galvo + MEMS Mirrors)

- Critical for generating 2D and 3D OCT volumes.

- Require angular precision <0.01°, low inertia, and high flatness mirrors (<λ/10).

- Reflective coatings optimized for 1060 nm, 1310 nm, or 1550 nm bands.

- Interferometric Beam Splitters and Couplers

- Use polarization-maintaining (PM) fiber splitters or free-space plate beamsplitters.

- Tolerances: surface flatness <λ/20, transmitted wavefront error <λ/10.

- Dielectric coatings must ensure 50:50 or custom ratio with <1% deviation.

- Focusing Optics (Scan Lens or Objective)

- Must deliver tight focus (high NA) with minimal aberration.

- Common types: achromatic doublets, GRIN lenses, or custom aspheres.

- Wavefront error must be <0.05λ RMS for optimal spot quality.

Advantages of High-Precision Optics in OCT

Benefit |

Resulting Performance Gain |

|---|---|

Lower wavefront error |

Enhanced image contrast and axial resolution |

Reduced chromatic aberration |

Consistent focus across wide spectral bandwidth |

High surface quality (e.g., 10-5) |

Minimal scattering and ghosting artifacts |

Stable thermal and mechanical design |

Maintains alignment over time and environmental shifts |

Manufacturing Challenges

- Tight Surface Figure and Roughness Requirements

- Challenge: Achieving sub-λ/10 surface accuracy while maintaining scratch-dig 10-5 or better.

- Solution: CNC polishing, magnetorheological finishing (MRF), and advanced interferometry-based QA.

- Broadband Dispersion Control

- Challenge: OCT systems often span >100 nm bandwidth; optics must not introduce chromatic mismatch.

- Solution: Use of achromats, dispersion-compensated coatings, and matched material pairs.

- Compact, Integrated Packaging

- Challenge: Endoscopic or handheld OCT probes demand miniaturized precision assemblies.

- Solution: Use of molded glass aspheres, monolithic lens barrels, and alignment-free bonding techniques.

- Coating Performance at NIR Wavelengths

- Challenge: Broadband AR coatings must maintain <0.5% reflectance across 800–1300 nm or 1000–1700 nm.

- Solution: electron beam evaporation coating.

Representative Examples of OCT Systems and Optical Design

Example 1: Ultra-High Resolution OCT for Retinal Imaging

System Type: Spectral-Domain OCT (SD-OCT)

Typical Wavelength: 840 nm ± 50 nm

Axial Resolution: Approximately 3 µm in tissue

Technical Highlights

- High-performance scan lenses designed to achieve diffraction-limited focusing (e.g., NA ~0.1, wavefront error <0.02λ RMS)

- Fused silica collimators with beam diameters around 8 mm and near-Gaussian beam quality (M² < 1.05)

- Broadband beamsplitters optimized for minimal dispersion and reflection losses

Application Impact

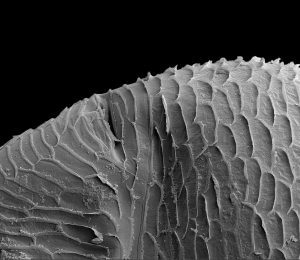

Such OCT systems are widely used in ophthalmology for visualizing fine retinal structures. The precision optics enable cellular-level imaging of the retina, including photoreceptor mosaics and nerve fiber layers. This level of resolution supports early diagnosis of conditions like age-related macular degeneration (AMD) and glaucoma.

Citation

- Wojtkowski, M., Bajraszewski, T., Gorczynska, I., Targowski, P., Kowalczyk, A., Wasilewski, W., & Radzewicz, C. (2004). Ultrahigh-resolution, high-speed, Fourier domain optical coherence tomography and methods for dispersion compensation. Optics Express, 12(11), 2404–2422.

- Drexler, W., Morgner, U., Ghanta, R. K., Kärtner, F. X., Schuman, J. S., & Fujimoto, J. G. (2001). Ultrahigh-resolution ophthalmic optical coherence tomography. Nature Medicine, 7, 502–507. /86589

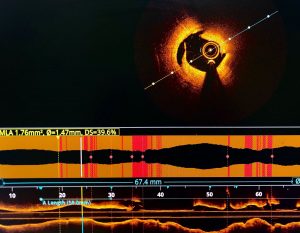

Example 2: Miniature Intravascular OCT Probes

System Type: Catheter-based Time-Domain OCT

Typical Wavelength: 1310 nm

Axial Resolution: Around 10 µm

Probe Diameter: Approximately 1.2 mm

Technical Highlights

- Custom GRIN lenses and microprism assemblies for compact light delivery

- Optical alignment maintained within ±5 µm eccentricity across full 360° rotation

- Final optics often achieve surface roughness below 5 Å RMS and are AR-coated for broadband operation (1310 ± 100 nm)

Manufacturing Considerations

- GRIN lens blanks may be produced via precision glass molding

- Optical elements are aligned using active optical feedback systems and UV-cured adhesives

- Optical assemblies are commonly tested pre-integration using fiber-coupled OCT interferometers

Application Impact

Miniaturized OCT probes are essential for intravascular imaging applications, enabling real-time imaging of coronary arteries with full circumferential coverage and shallow penetration depths. This facilitates early detection of plaque and vascular abnormalities.

Citation

- Tearney, G. J., Regar, E., Akasaka, T., Adriaenssens, T., Barlis, P., Bezerra, H. G., … & Serruys, P. W. (2012). Consensus standards for acquisition, measurement, and reporting of intravascular optical coherence tomography studies: a report from the International Working Group for Intravascular Optical Coherence Tomography Standardization and Validation. JACC. 2012 Mar, 59 (12) 1058–1072

- Wang, L. V., & Wu, H. I. (2012). Biomedical Optics: Principles and Imaging

(Ch. 7). Wiley-Interscience.

Achieving Micron-Scale Resolution & Low-Noise OCT

High-precision optics are the backbone of OCT systems. Whether it’s a benchtop system for retinal diagnostics or a catheter probe for cardiovascular imaging, achieving micron-scale resolution and low-noise performance demands optics with near-perfect surface figures, ultra-low aberration, and consistent broadband performance.

By combining advanced materials, fabrication methods, and optical design, engineers can now deliver compact, rugged, and highly accurate OCT optics that unlock new frontiers in biomedical imaging and diagnostics.

GREAT ARTICLE!

Share this article to gain insights from your connections!