Key Takeaways

- Space-based telescopes are evolving rapidly, with growing demand for compact, high-performance optical systems.

- Freeform optics enable miniaturized designs, while SiC mirrors offer stability and low mass for harsh space environments.

- Lightweight structures are essential for both CubeSat payloads in LEO and large observatories in deep space.

- Across mission sizes, the trend is clear: optical systems must deliver precision, durability, and thermal resilience. Partnering with an experienced optics manufacturer is key to mission success.

Trends in Space-Based Telescopes: From SmallSat Payloads to Deep Space Observatories

Emerging Needs: Freeform Optics, SiC Mirrors, Lightweight Designs

As space exploration advances, the demands on optical payloads are rapidly evolving. From compact CubeSats to flagship deep space observatories, today’s space-based telescopes require innovations that balance high performance with extreme environmental resilience. Key trends are reshaping optical design—most notably the adoption of freeform optics, silicon carbide (SiC) mirrors, and lightweight optical structures.

The Push for Compact, High-Performance Payloads

SmallSats and CubeSats have transformed the landscape of satellite-based imaging and sensing. These platforms require optical systems that deliver high-resolution performance in tight mass, volume, and power constraints. Designers are now embracing:

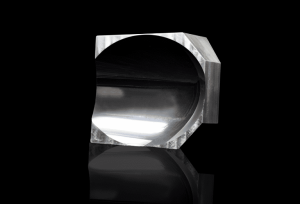

- Freeform Optics: By moving beyond rotationally symmetric elements, freeform surfaces enable compact, off-axis designs that reduce the number of optical elements while correcting aberrations more effectively.

- Folded Optical Paths: Fold mirrors allow for longer effective focal lengths in small envelopes—ideal for maximizing resolution in SmallSat telescopes.

Material Innovation: Silicon Carbide (SiC) for Precision Mirrors

For both near-Earth and deep-space missions, mirror substrate material is critical. Silicon carbide (SiC) is increasingly favored due to its:

- High stiffness-to-weight ratio

- Low coefficient of thermal expansion (CTE)

- Excellent thermal conductivity

These properties allow SiC mirrors to maintain optical stability in extreme temperatures and mechanical loads. From hyperspectral imaging satellites to planetary telescopes, SiC-based optics support precision imaging under challenging mission profiles.

Lightweight Design Without Performance Compromise

Reducing mass is essential for space missions—lower launch costs, extended lifetimes, and easier maneuverability. Optical engineers are achieving this through:

- Lightweight mirror substrates (e.g., honeycomb-structured backs)

- Athermalized optical designs

- Precision alignment features integrated into the mechanical structure

Advanced manufacturing techniques, such as CNC machining of SiC and additive manufacturing of mounts and baffles, are pushing the boundaries of what is possible in lightweight optical systems.

From LEO to Deep Space: Scaling Optical Innovation

While CubeSats and SmallSats push miniaturization, flagship telescopes like those used in exoplanet discovery or cosmic background imaging push the boundaries of scale and sensitivity. The same trends—freeform optics, SiC mirrors, and lightweight assemblies—scale across mission sizes. In deep space, optical components must also:

- Resist radiation damage

- Survive long-duration thermal cycling

- Maintain nanometer-level figure accuracy over years

This convergence in design philosophy across platforms is fostering modular optics, multi-mission adaptability, and more efficient development pipelines.

Partnering with a Manufacturer That Understands Space Optics

At Avantier, we specialize in custom optical components engineered for spaceflight. Whether you’re designing a CubeSat imager, a LEO Earth observation telescope, or a deep-space optical instrument, we bring:

- Expertise in freeform and aspheric optics

- In-house SiC polishing and metrology

- Flight-proven bonding, alignment, and environmental testing

Let’s collaborate to turn your optical design into a mission-ready reality.

GREAT ARTICLE!

Share this article to gain insights from your connections!