Key Takeaways:

- Micro- and nano-scale 3D printing transforms microlens fabrication with high-resolution, mold-free production and rapid prototyping.

- This manufacturing method works well with diverse materials and enables multifunctional optics like GRIN and tunable lenses.

- Key applications of 3D printed microlenses include biomedical imaging, OCT, flow cytometry, optical sensing, fiber optics, and laser beam shaping.

- Mofang Precision’s PμSL technology, offered by Avantier, delivers ultra-precise, customizable microlenses with fast turnaround and seamless integration—ideal for advanced optical systems and R&D.

Micro- and Nano-Scale 3D Printed Microlenses

The rise of micro- and nano-scale 3D printing is transforming the fabrication of microlenses, enabling breakthroughs in optics, biomedical imaging, and telecommunications. These miniature lenses are key to controlling light propagation, adjusting focal lengths, and shaping beam profiles in high-precision applications such as microscopic imaging, laser beam shaping, and optical sensing.

Traditional microlens manufacturing methods—like photolithography and micro-milling—deliver high precision but struggle with complex geometries, fast prototyping, and cost-efficiency. Micro- and nano 3D printing overcomes these limitations by offering exceptional resolution, customization, and rapid production capabilities.

What Is Micro- and Nano-Scale 3D Printing?

Micro- and nano-scale 3D printing is an advanced additive manufacturing technique that builds optical microstructures layer by layer. Unlike conventional subtractive methods, this approach allows for complex, mold-free designs and ultra-fine resolutions—often at the sub-micron or nanometer scale.

This technology dramatically reduces production time and is ideal for fabricating the custom microlenses, micro-optics, and precision microstructures used in cutting-edge optical systems.

Benefits of 3D Printed Microlenses

1. Ultra-High Precision & Design Freedom

3D printing achieves sub-micron accuracy without relying on photomasks or intricate tooling. This enables the creation of freeform optics, aspheric lenses, and other custom shapes that traditional techniques can’t easily replicate.

2. Rapid Prototyping & On-Demand Customization

3D-printed microlenses can be produced within hours, significantly reducing development time. This is particularly valuable for R&D, pilot production, and applications requiring tailored optical designs.

3. Broad Material Compatibility

The process can be used with a wide range of materials—from transparent resins optimized for optics to metallic and ceramic materials for enhanced durability and thermal resistance.

4. Integrated Multifunctional Features

3D printing enables seamless integration of multiple optical functions within a single lens. For instance, gradient-index (GRIN) lenses, tunable-focus microlenses, and beam-shaping structures can be printed in one step using varying material properties or geometries.

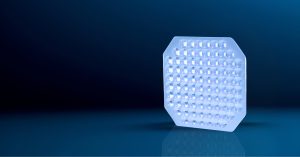

Mofang Precision’s Projection Micro-Stereolithography (PμSL) technology exemplifies this capability. It supports ultra-high-resolution printing of microlens arrays and is compatible with PDMS molding, making it ideal for advanced prototyping and optical R&D.

Key Applications of 3D Printed Microlenses

- Biomedical & Microscopic Imaging: High-resolution microlens arrays enhance contrast and resolution in microscopy and biomedical imaging systems. This makes them ideal for miniaturized and high-performance optical modules.

- Optical Sensors & Environmental Monitoring: Microlenses improve light collection and signal focusing in optical sensors. 3D printing makes possible the production of miniaturized, application-specific lenses integrated directly into sensor modules. It’s this precision integration that provides the sensitivity needed for biosensing, chemical detection, and air quality monitoring.

- Optical Coherence Tomography (OCT) & Flow Cytometry: This 3D printing technology is also highly applicable to OCT and flow cytometry, where precise light control and miniaturized optics are crucial for signal detection, beam focusing, and imaging within compact biomedical systems.

- Fiber Optic Communications: Custom microlenses improve light coupling in fiber optic systems, supporting more efficient transmission, modulation, and detection in high-speed networks. 3D printing ensures precise alignment and compact integration for these advanced photonics components.

- Laser Beam Shaping & Control: Microlenses are critical for shaping laser beams in applications such as laser machining, medical lasers, and 3D laser printing. 3D-printed optics allow for fine-tuned control over beam profiles, improving processing accuracy and system efficiency.

Your Custom Microlens Project with Avantier

Are you looking to develop advanced micro-optical components? Our engineering team at Avantier is here to help. Whether you need prototyping support, material guidance, or full-scale production, we offer tailored solutions for your most complex optical challenges.

📩 Contact us today to discuss your requirements.

📄 Request a quote for custom 3D-printed microlenses and microlens arrays.

Let’s bring your project to life—efficiently and accurately.

GREAT ARTICLE!

Share this article to gain insights from your connections!