Key Takeaways

- Avantier specializes in precision optical design tailored for 3D imaging systems, ensuring optimal performance in vision systems crucial for various industries.

- Their process begins with consolidating client requirements, tailoring components to specific needs across industries like medicine, research, and defense.

- Expert collaboration and iterative design refinement yield optimized lens systems, maximizing focus, f-number stability, and pointing accuracy.

- Rigorous quality control and environmental testing ensure Avantier’s components meet stringent performance standards, facilitating seamless integration and enhanced operational efficiency.

The Impact of 3D Scanning Technology

No longer do we record the world in two dimensions: 3D scanning technology has taken the world by storm. Whether you’re designing avatars in popular culture, using LIDAR sensors for autonomous driving, or controlling robots with 3D sensors that observe their environment in real-time, you’re taking advantage of advances in 3D imaging. Medical technology relies on 3D imaging for diagnostics and treatment planning, and industry uses 3D scanners to run quick, complete inspections of products and components. Virtual reality is another field in which creating a three-dimensional image in real time enables the delivery of an immersive experience.

When you’re working in 3D multicamera measurement applications, enabling machine vision systems to determine their environment down to the nearest pixel, precision matters. Repeatability and reliability are crucial. If you’re to have a machine vision system you can depend on, you’ll need well-designed instrumentation, good calibration, and high pointing accuracy. High quality design is where it all begins.

How We Design for 3D Imaging

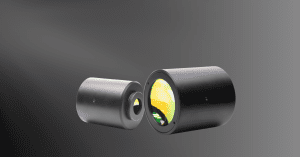

Avantier works with clients in industry, medicine, research, and defense to create custom components and systems for 3D imaging. Our lens design workflow follows a simple schema:

- Consolidate a list of your requirements and specifications. 3D components are never one size fits all, and to make the ideal part for your system we first need to know what your specs and requirements are.

- Create the initial tentative design, working with experts from various fields to ensure the lens will fulfill its purpose as intended.

- With input from reviews, develop a final design that matches all requirements and specifications, using design for manufacturing principles.

- Determine appropriate coatings for each part of the system or lens to optimize performance

- Determine appropriate manufacturing tolerances, and decide on quality checks and environmental testing that ensures that the piece will work as desired.

When designing lenses for 3D systems we focus on features that will allow them to maintain optimum focus and operate at a constant f-number, as well as maintain good pointing accuracy and constant magnification. If we’ve got this right, future calibration and the analysis done by your software will be that much easier.

GREAT ARTICLE!

Share this article to gain insights from your connections!