Key Takeaways

- Advanced wavefront sensors are fundamental to high-precision optical metrology and control across fields such as ophthalmology, semiconductor inspection, astronomy, and emerging space and laser systems.

- Their performance depends on refined optical design—particularly custom microlens arrays, coatings, and detectors that enhance accuracy, sensitivity, and dynamic range.

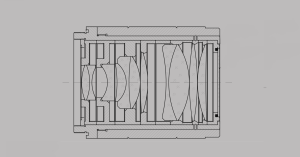

- This article explores how tailored optics and adaptive components enable precise wavefront reconstruction, real-time correction, and compact integration—key for applications from telescope alignment and interferometer stabilization to advanced imaging and beam-shaping systems.

📌 Explore our Optical Design Services to support your next sensor innovation.

Why Custom Optics Matter in Wavefront Sensors

Standard optical components often fall short in demanding wavefront sensing applications. Custom-designed optics enable significant performance enhancements in resolution, sensitivity, and speed.Key Design Elements

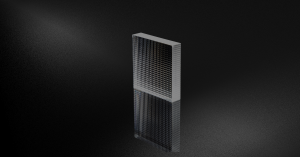

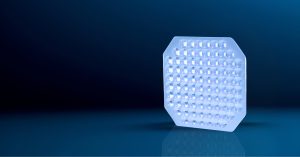

- Microlens arrays are the core component in Shack-Hartmann wavefront sensors; their custom specifications directly impact system resolution, sensitivity, and accuracy.

- Customized detectors and coatings improve light capture, reduce noise, and ensure compatibility with the microlens configuration.

- Advanced fabrication techniques, such as binary optics and hybrid-layer structures, unlock new design flexibility and performance levels.

- Adaptive optical elements provide real-time tunability, making sensors more versatile in dynamic environments.

- Integration with computational imaging and AI is paving the way for faster, more accurate wavefront reconstruction.

- Application-specific customization delivers superior results compared to general-purpose designs.

- Emerging technologies such as MEMS deformable mirrors, spatial light modulators, and chip-scale sensors are further enhancing the capabilities and versatility of wavefront sensing systems.

How Wavefront Sensors Work

Wavefront sensors measure the deviation of an optical wavefront from its ideal shape. In a Shack-Hartmann configuration—the most widely used design—a wavefront passes through a microlens array. Each microlens focuses a portion of the wavefront onto a detector. When the wavefront is flat, these focal spots form a regular grid. Any aberration displaces the spots, and by analyzing these displacements, the sensor reconstructs the entire wavefront profile.

This capability is essential for applications requiring nanometer-scale precision, where even minor deviations can compromise system performance.

The Role of Customized Optics

The accuracy and sensitivity of wavefront sensors depend heavily on the quality and customization of their optical components. Standard off-the-shelf solutions often fall short of the demands in precision optics, making bespoke design essential. Microlens Arrays Microlens arrays are the heart of Shack-Hartmann sensors. Custom parameters can optimize:

Parameter |

Impact |

Pitch |

Sampling resolution |

Focal Length |

Sensitivity & dynamic range |

Array Geometry |

Beam shape compatibility |

Surface Quality |

Measurement accuracy |

Detector Matching & Alignment

- High-performance CMOS or CCD

- Sub-pixel centroiding algorithms

- Custom mechanical alignment ensures fidelity

Optical Coatings

- AR Coatings: Minimize ghosting and stray light

- Wavelength-Specific: Optimize for UV, VIS, IR

- Multi-layer Designs: Support broadband performance

Customization Techniques for Advanced Wavefront Sensors

Binary Diffractive Optics

- Use lithography to create phase-modulating structures

- Sub-wavelength control of light for compact, multifunctional components

Hybrid Microlens Structures

- Dual-layer lenses with multiple refractive indices

- Reduce spherical aberration without increasing size

Adaptive Optics & Emerging Elements

- Electrically tunable microlens arrays

- MEMS deformable mirrors for compact real-time correction

- Spatial light modulators (SLMs) for dynamic beam shaping

Innovations in Detection & Data Processing

- Phase & Intensity Sensors: Simultaneous capture in a single frame

- Real-Time Reconstruction: GPU-based or ML-assisted processing

- Software SDKs: Custom control and data analysis workflows

Miniaturization & Embedded Systems

Wavefront sensors are becoming smaller and faster:- MEMS-based mini sensors for mobile applications

- Photonic integration allows wavefront detection on a chip

- Real-time correction for handheld biomedical or field devices

Applications of Customized Wavefront Sensors

Wavefront sensors with customized optics are widely deployed across industries:

Industry | Application |

Ophthalmology | LASIK, IOL design, higher-order aberration mapping |

Optical Fabrication | Real-time surface inspection & alignment |

Laser Beam Shaping | Pulse & beam quality optimization |

Astronomy | Atmospheric compensation for telescopes |

Quantum Optics | Precise phase control |

Bioimaging | Label-free quantitative phase imaging |

Optical Design Example: Custom Microlens Array in Laser Lithography

A semiconductor equipment maker needed nanometer-level wavefront control in a laser lithography system. Standard MLAs lacked the required performance. Solution: A hybrid microlens array with:- Non-standard pitch

- Extended focal length

- UV-optimized coating for 193 nm

- +30% beam shaping accuracy

- –45% calibration time

- Increased yield and process stability

Emerging Trends in Wavefront Sensing Technology

Wavefront sensing is advancing rapidly, driven by several key trends:- Miniaturization: Chip-scale wavefront sensors and photonic integration enable compact, embedded solutions.

- Computational Enhancement: Machine learning and neural networks accelerate wavefront reconstruction and improve accuracy.

- System Integration: Monolithic and hybrid designs reduce system complexity and improve mechanical stability for field-deployable instruments.

- MEMS and SLM Integration: The use of MEMS deformable mirrors and spatial light modulators is expanding, enabling adaptive optics in smaller, more robust packages.

- Real-Time, High-Speed Sensing: Ultra-fast acquisition and processing are making wavefront sensors suitable for live imaging, high-throughput manufacturing, and adaptive laser systems.

Conclusion

Custom optical design is the cornerstone of high-performance wavefront sensors. From advanced microlens arrays to adaptive optics and computational control, tailored components enable nanometer-level accuracy, real-time correction, and compact system design.

As technology evolves, precision optics will continue to push the boundaries of wavefront sensing—making them smarter, smaller, and more versatile than ever.

Looking to Build a Custom Wavefront Sensor?

Let’s design it together.

🔧 Contact Our Optical Design Team!

GREAT ARTICLE!

Share this article to gain insights from your connections!