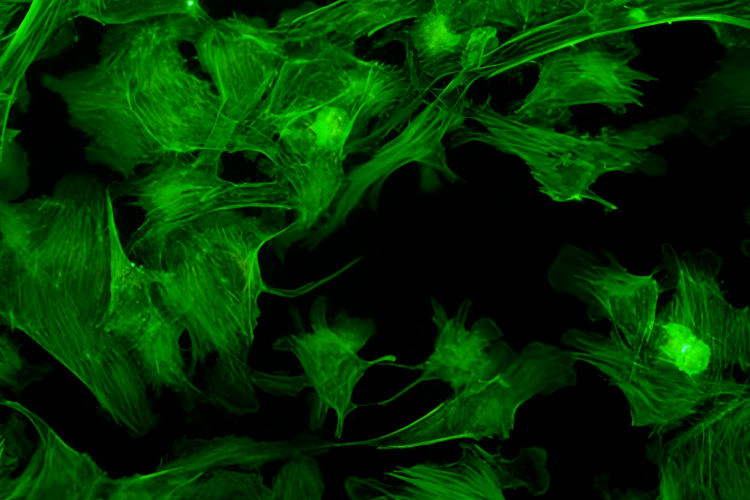

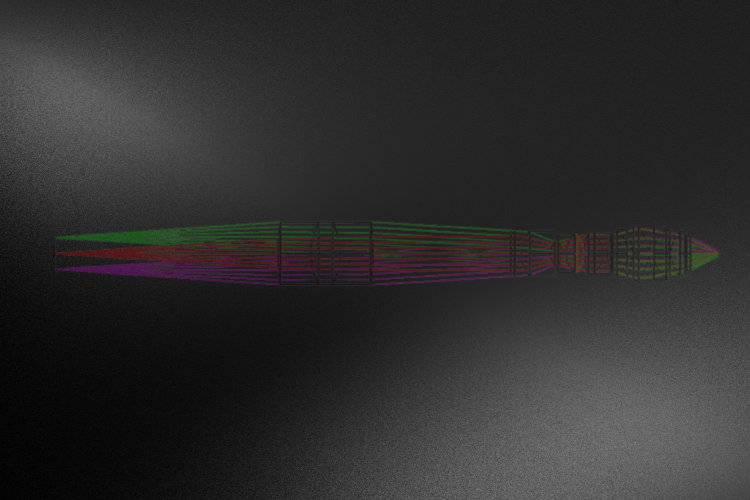

Near-infrared (NIR) microscopy objectives (780–2500nm) are essential for “seeing through” opaque barriers.

By balancing high resolution with superior penetration, they enable deep-tissue biological imaging, subsurface semiconductor defect detection, and non-destructive material analysis.

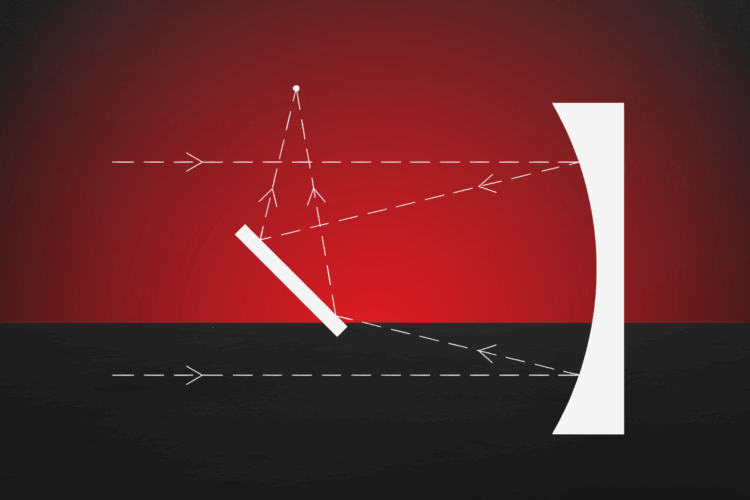

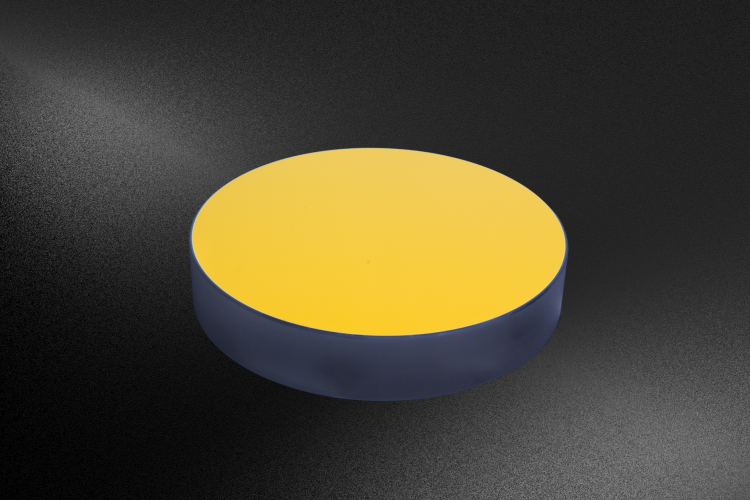

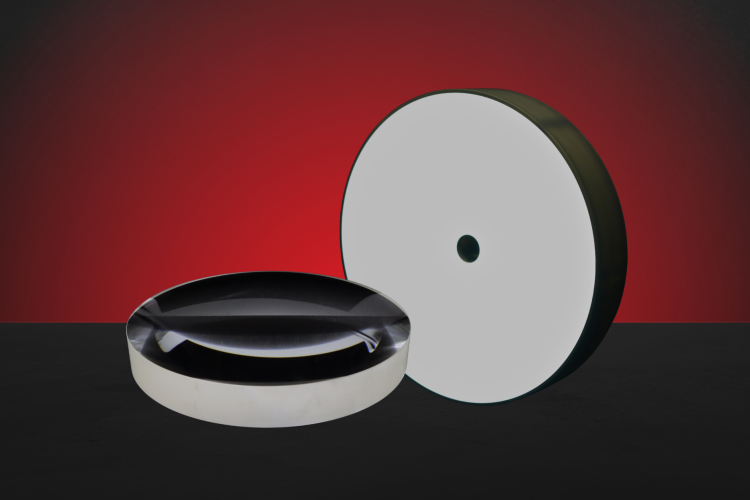

Despite design challenges like specialized material selection (ZnS/Germanium) and complex aberration correction, modern NIR optics provide high-transmittance solutions (≥ 85%) that surpass the physical limits of visible light, driving innovation in both high-tech manufacturing and life sciences.