Key Takeaways

- Fiber lasers (1.06 μm) excel in aerospace, defense, and medical sectors due to superior beam quality, efficiency (30–40%), compact design, and strong metal absorption, making them ideal for precision welding, micro-drilling, and high-energy defense systems.

- CO₂ lasers (10.6 μm) remain unmatched for non-metals and biological tissues, excelling in composites, ceramics, polymers, and soft-tissue ablation.

- Choice depends on application: fiber lasers dominate metal-intensive, high-precision tasks, while CO₂ lasers lead in dielectric, polymer, and medical tissue applications. Hybrid systems are emerging.

1. Fundamental Laser Physics

- CO₂ Lasers

- Gain Medium: Gas mixture (CO₂, N₂, He).

- Wavelength: 10.6 μm (far-infrared).

- Mode of Operation: Excitation via electrical discharge across gas; typically continuous-wave (CW) or pulsed.

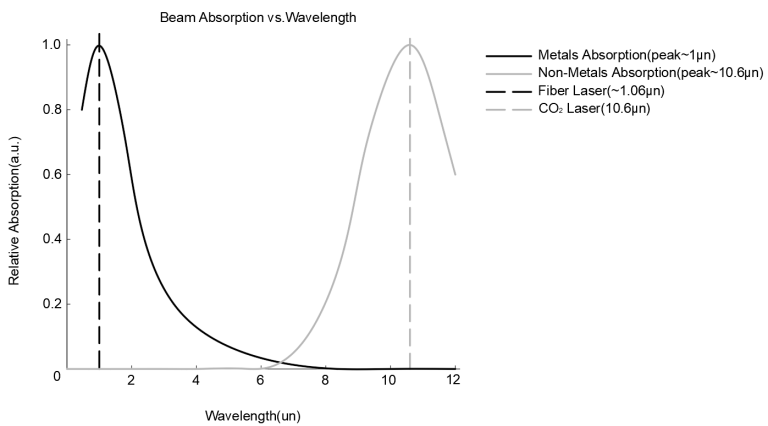

- Photon-Material Interaction: Strong absorption by dielectrics, ceramics, polymers, water-rich tissues; weaker absorption in metals unless surface is pre-treated (e.g., with coatings).

- Gain Medium: Gas mixture (CO₂, N₂, He).

- Fiber Lasers

- Gain Medium: Rare-earth doped silica fibers (commonly ytterbium, sometimes erbium or thulium).

- Wavelength: ~1.06 μm (near-infrared).

- Mode of Operation: Pump diodes excite the doped core, light is amplified along the fiber.

- Photon-Material Interaction: High absorption in metals, efficient coupling into small spots due to shorter wavelength.

- Gain Medium: Rare-earth doped silica fibers (commonly ytterbium, sometimes erbium or thulium).

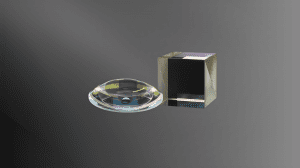

2. Beam Characteristics and Efficiency

Metric |

CO₂ Laser |

Fiber Laser |

Wavelength |

10.6 μm |

1.06 μm |

Beam Quality (M²) |

~1.2–3 |

~1.05 (diffraction-limited possible) |

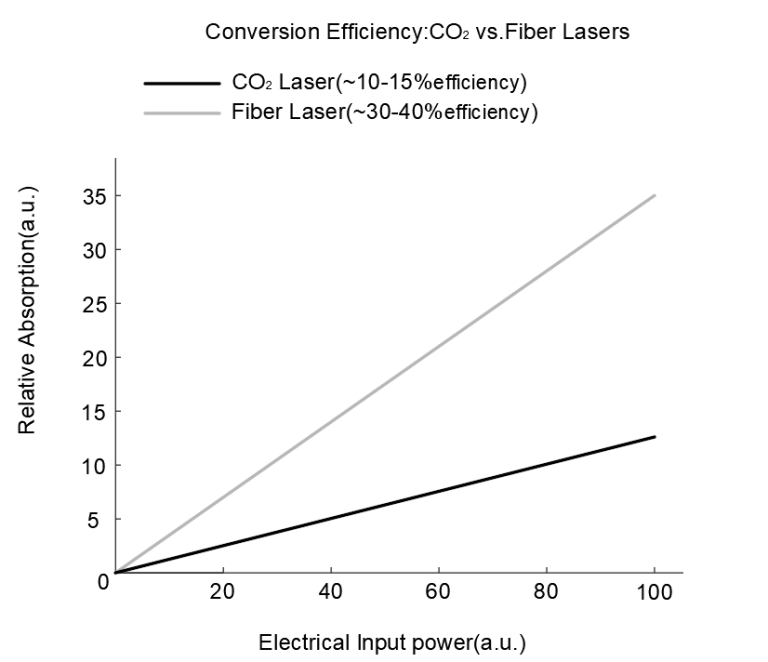

Conversion Efficiency |

10–15% |

30–40% |

Spot Size |

Larger (≥100 μm typical) |

Smaller (10–30 μm typical) |

Maintenance |

Regular gas refills, optics alignment |

Minimal (sealed fiber design, diode lifetime >100k hrs) |

- Aerospace and defense applications requiring fine features in metals (e.g., micro-drilling in turbine components, welding of titanium alloys) benefit from fiber lasers.

- CO₂ lasers remain technically advantageous where larger spot sizes and deep penetration in non-metals are required (e.g., composites, ceramics).

3. Material Processing Performance

- Metals

- Fiber lasers: Superior due to shorter wavelength, better coupling with reflective metals (aluminum, copper, titanium). Achieve narrow kerf widths, high cutting speeds, and reduced heat-affected zones (HAZ).

- CO₂ lasers: Struggle with reflective metals; lower efficiency; require higher power or surface pretreatments.

- Fiber lasers: Superior due to shorter wavelength, better coupling with reflective metals (aluminum, copper, titanium). Achieve narrow kerf widths, high cutting speeds, and reduced heat-affected zones (HAZ).

- Non-Metals

- CO₂ lasers: Excels in cutting and engraving plastics, ceramics, composites, glass. Their wavelength is absorbed strongly by carbon-based materials and water, making them unmatched for medical tissue ablation.

- Fiber lasers: Limited effectiveness with transparent or non-metallic materials.

4. Reliability and System Engineering

- CO₂ Lasers

- Larger footprint with free-space optics.

- Sensitive to misalignment, contamination, and require periodic gas replacement.

- Cooling systems essential due to lower electrical-to-optical efficiency.

- Larger footprint with free-space optics.

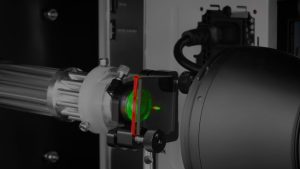

- Fiber Lasers

- Compact, monolithic design with no moving parts in the beam path.

- Fiber delivery allows easy beam routing through robotics and gantry systems.

- Compact, monolithic design with no moving parts in the beam path.

High reliability in harsh environments — ideal for mobile military applications and aerospace manufacturing floors.

5. Sector-Specific Implications

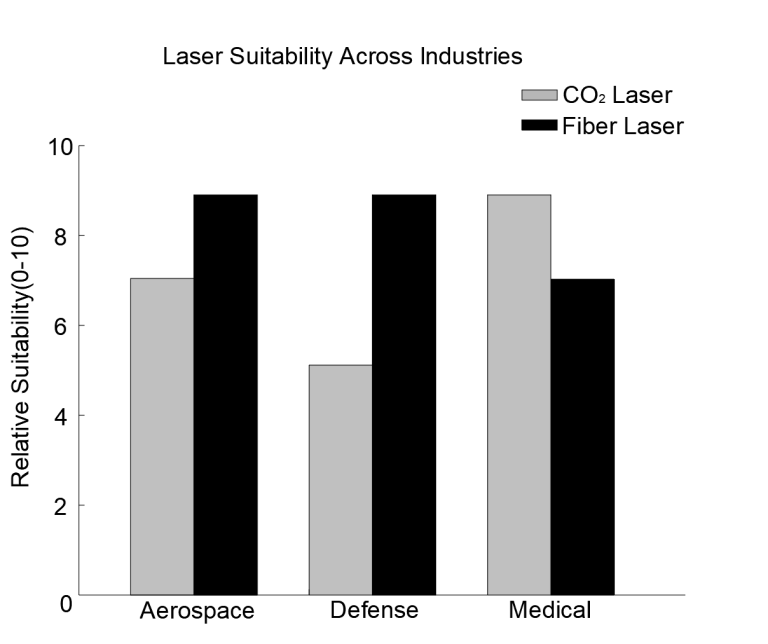

Aerospace

- Fiber Lasers: Micro-perforation of turbine blades (for cooling holes <200 μm), welding of lightweight alloys (Al, Ti, Ni), precision cutting of structural metals.

- CO₂ Lasers: Cutting thermal barrier coatings (ceramics), trimming polymer composites, and processing insulation materials.

Defense

- Fiber Lasers: Scalable high-energy laser (HEL) systems (10–100 kW range) due to modularity, ruggedness, and efficiency. Used for anti-drone systems, precision weapon integration.

- CO₂ Lasers: Historically employed in directed-energy research (megawatt-class systems), but bulky and less practical for field deployment.

Medical

- Fiber Lasers: Precision welding of implantable devices (stents, pacemakers, surgical tools) requiring micron-level control.

- CO₂ Lasers: Surgical gold standard for dermatology, dentistry, and soft-tissue procedures. The 10.6 μm wavelength is absorbed by water in cells, enabling precise ablation with minimal collateral damage.

6. Emerging Trends

- Hybrid Systems: Some aerospace and medical device manufacturers employ dual-laser setups—fiber for precision cutting/welding of metals and CO₂ for processing composites or biological samples.

- Ultrashort-Pulse Fiber Lasers (femtosecond / picosecond): Expanding into micromachining for aerospace and minimally invasive medical devices, where heat input must be minimized.

- Defense R&D: Fiber-based HEL systems are advancing rapidly due to compactness and scalability, gradually displacing CO₂ in mobile platforms.

7. Conclusion

From a technical perspective:

- Fiber lasers are superior in metal-intensive, high-precision, high-efficiency applications — making them the choice for aerospace manufacturing, defense HEL systems, and medical device fabrication.

- CO₂ lasers remain unmatched in non-metal and biological applications, where their longer wavelength interacts strongly with organic and dielectric materials.

For engineering leaders in aerospace, defense, and medical industries, the selection is not about “which is better” but about matching laser physics to material properties and mission requirements.

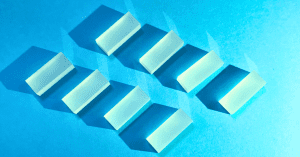

Beam Absorption vs. Wavelength – showing why fiber lasers (1.06 µm) are ideal for metals and CO₂ lasers (10.6 µm) excel with non-metals and biological tissues.

Efficiency Curves – highlighting the significantly higher electrical-to-optical conversion efficiency of fiber lasers.

Application Suitability Chart – comparing relative strengths of CO₂ and fiber lasers across aerospace, defense, and medical industries.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!