Introduction: Large Aperture OAP Mirrors in Holography Optics

Large-aperture off-axis parabolic (OAP) mirrors are critical components in advanced optical research and engineering. Their ability to deliver high imaging quality, wide spectral performance, and robust handling of high-power beams makes them indispensable for applications such as holography, diffractive optics, astronomy, and laser systems.

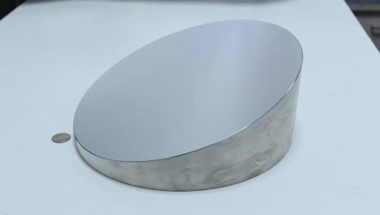

At Avantier, we recently collaborated with a research group to design and manufacture custom large OAP mirrors—ranging from 200 mm to 400 mm in diameter—along with a precision-engineered flat mirror. This case study highlights the technical challenges, engineering solutions, and broader implications of the project.

Project Background: Custom Engineering Large Aperture OAP Mirrors

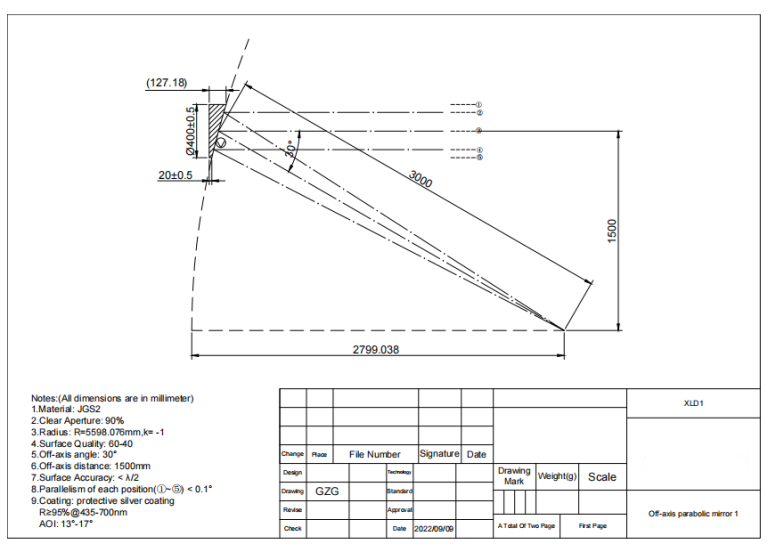

The customer’s initial request for quotation included:- Three OAP mirrors: diameters of 200 mm, 300 mm, and 400 mm

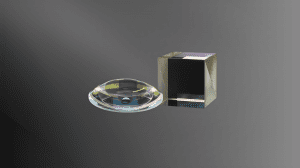

- One flat mirror: 400 × 250 × 20 mm

Customer Challenges in Producing Large Aperture OAP Mirrors

The customer faced multiple technical and design obstacles:- Manufacturability of large OAPs: Scaling mirrors beyond 300 mm introduces significant complexity in focal length and off-axis angle optimization.

- Structural stability of the flat mirror: To maintain surface figure quality, a minimum thickness of 20 mm was necessary.

- Iterative design process: Frequent revisions were required during proof-of-concept testing and simulation, which meant rapid updates to specifications and quotations.

Tailored Solutions for Holography Optics

Our team provided end-to-end engineering consultation throughout the project lifecycle. Key contributions included:- Material selection: Recommended JGS2 fused silica as the optimal balance of machinability, thermal stability, and cost-effectiveness.

- Coating guidance: Confirmed silver as the best reflective coating for the target spectral range.

- Design optimization: Suggested modifications to effective focal length and off-axis angle to ensure manufacturability while meeting performance requirements.

- Structural integrity: Specified flat mirror thickness at 20 mm to maintain accuracy without excessive weight.

Why Large Aperture OAP Mirrors Are Vital for Holography Optics

Optical Advantages

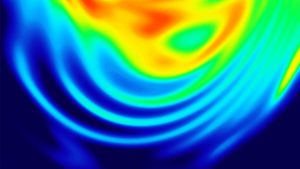

- Unobstructed optical path: Off-axis design eliminates central obstruction, enhancing transmission efficiency and image contrast.

- Broad spectral performance: Reflective design ensures colorless operation across UV, visible, IR, and terahertz bands.

- Aberration control: Advanced designs (e.g., three-mirror systems) effectively suppress coma and other monochromatic aberrations, achieving near-diffraction-limited imaging.

Structural and Application Benefits

- Compact, lightweight systems: Off-axis layouts reduce system volume by up to 50% compared to refractive optics, a major advantage for space-based and mobile applications.

- High laser damage threshold: Reflective design avoids thermal lensing and supports ultra-high-power laser beams.

- Multi-band compatibility: Single mirror systems can serve multi-spectral fusion applications.

Manufacturing Challenges

Producing large-aperture OAP mirrors is among the most demanding tasks in precision optics. Challenges include:

- Material preparation: Managing internal stresses and homogeneity in large fused silica blanks.

- Complex free-form machining: Off-axis geometries lack symmetry, requiring multi-axis CNC milling, extended grinding, and precise trajectory control.

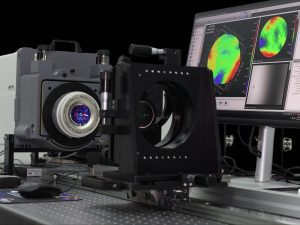

- Deterministic polishing: Techniques such as ion beam figuring are essential to achieve molecular-level accuracy.

- Testing complexity: Interferometric measurement requires custom compensators, environmental controls, and advanced benchmarking assembly methods.

Avantier’s experience in diamond turning, ion beam polishing, and interferometric testing ensured these challenges were successfully managed.

Applications and Market Impact

Immediate Use Case: Holography and Diffractive Optics

The delivered mirrors now play a central role in the customer’s holographic recording experiments and diffractive optics research, enabling precise beam control and stable optical path alignment.

Broader Industry Applications

Large-aperture OAP mirrors are driving innovation across multiple high-end sectors:

- Space Remote Sensing: Off-axis tri-mirror designs deliver wide fields of view, minimal stray light, and high SNR for Earth observation.

- Astronomy and Deep Space Exploration: Ultra-large OAPs improve contrast in telescopes, critical for exoplanet detection.

- Laser Systems: Essential for high-power laser processing, avoiding damage and enabling kilowatt-level beam handling.

- Synchrotron Beamlines: Precision OAPs maintain beam quality under extreme radiation.

- Terahertz Technology: Gold-coated OAPs provide efficient THz wave transmission for advanced spectroscopy.

Market Segment

This project contributes to the advanced optics and materials research sector, particularly in photonic devices, next-generation displays, and optical sensors, where high-precision custom mirrors are foundational.

Future Outlook

The demand for meter-class off-axis mirrors is rising in astronomy and space science. Advances in materials science, deterministic polishing, and AI-driven process optimization are rapidly pushing the boundaries of manufacturability.

We anticipate expanding applications beyond traditional research into medical imaging, VR/AR systems, and autonomous sensing, as costs decrease and technology matures.

Advancing Holography Optics with Large Aperture OAP Mirrors

This project demonstrates Avantier’s ability to deliver custom-engineered, large-aperture OAP mirrors that meet the stringent demands of cutting-edge holography and diffractive optics research. By addressing manufacturing challenges, optimizing design, and providing technical consultation, we ensured reliable, high-performance components tailored to the customer’s needs.

At Avantier, we continue to push the boundaries of optical engineering. If your project requires custom off-axis parabolic mirrors—from 50 mm to meter-class—our team is ready to collaborate.

👉 Contact us today to discuss your custom optical requirements.

GREAT ARTICLE!

Share this article to gain insights from your connections!