Key Takeaways:

- Diamond-like carbon (DLC) films possess diamond-like properties, offering excellent mechanical durability, corrosion resistance, optical clarity, and thermal performance.

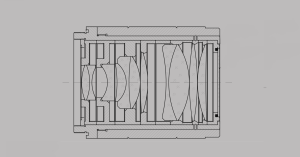

- Widely used in electronics, optics, and biomedicine, DLC films are crucial in infrared objective lenses that operate across multiple infrared bands (1-3 µm, 3-5 µm, 8-14 µm).

- These lenses, often exposed to harsh environments, benefit from DLC coatings that improve transmittance, reduce friction, and enhance durability.

- DLC coated IR lenses undergo rigorous environmental testing to ensure optimal performance, making them ideal for demanding applications like temperature measurement, security, and military reconnaissance.

Overview of DLC film

Diamond-like carbon film (DLC Film) is a type of carbon film that possesses properties similar to diamond. Known as a hard carbon film, DLC is an amorphous carbon material with a diamond-like structure. While the DLC process is more mature than diamond film production, DLC still boasts a range of excellent properties.

- Mechanical properties: DLC films exhibit high hardness and friction resistance, making them ideal for mechanical tools, extending the service life of devices.

- Corrosion resistance: DLC films have high chemical inertness, acting as a protective layer to prevent chemical reactions between the substrate and external elements.

- Optical properties: DLC films have a refractive index between 1.5 – 2.3, with less than 1% absorption in the infrared band, resulting in high transmittance.

- Thermal performance: As high thermal conductivity insulators, DLC films can serve as heat dissipation substrates for high-power electrical components, improving device stability.

With these outstanding qualities, DLC films have a broad range of applications in electronics, machinery, optics, and biomedicine.

Application of DLC Film in Infrared Objective Lenses

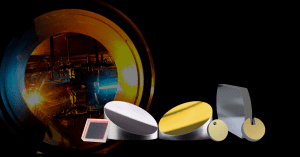

Infrared objective lenses are designed for use in the infrared spectrum, specifically across the 1-3 µm, 3-5 µm, and 8-14 µm bands, commonly referred to as the atmospheric windows. These lenses are widely used in temperature measurement, medical diagnostics, security surveillance, forest fire prevention, agriculture, military reconnaissance, tracking, and guidance.

Infrared objective lenses are frequently exposed to harsh environments, such as marine and metallurgical conditions, making lens coatings particularly important. Materials like silicon and germanium, often used in infrared lenses, have high refractive indices. Anti-reflection coatings must be applied to minimize energy loss.

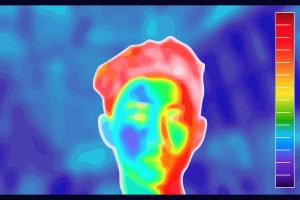

DLC coated IR lens

DLC films possess a wide optical bandgap, high transmittance, and low absorption in the infrared spectrum. With their high hardness, low friction coefficient, and excellent chemical stability, DLC films are ideal as anti-reflection/protective coatings for various optical materials, including silicon, germanium, glass, and zinc sulfide. They are especially suited for infrared optical components with single-layer anti-reflection coatings. DLC coatings enhance infrared transmittance, improve imaging capabilities, and extend the service life of infrared objective lenses.

DLC films act as a protective barrier, shielding lenses from environmental exposure. DLC-coated lenses undergo rigorous environmental testing, which typically includes: temperature cycle, temperature and humidity resistance, wear resistance, salt spray exposure, solubility resistance, etc.

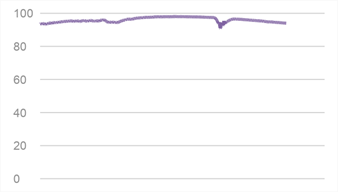

The spectral characteristics of DLC-coated optical elements are also key performance indicators. Below is an example of a silicon window piece with a diameter of 200 mm. One side is coated with a DLC film, while the other side is coated with a conventional AR film.

Large aperture silicon Windows and spectral curves of 3-5um

Expanding Application of DLC film

Diamond-like carbon (DLC) films offer a versatile solution for enhancing the performance and longevity of infrared objective lenses, especially in harsh and demanding environments. With their exceptional mechanical durability, corrosion resistance, high transmittance, and low absorption in the infrared spectrum, DLC films significantly improve the imaging quality and durability of optical systems.

DLC coatings extend beyond infrared lenses, playing a vital role in electronics, biomedicine, and precision machinery. They not only provide robust protection but also optimize optical performance by reducing energy loss and increasing component lifespans. Rigorous testing ensures that DLC-coated lenses meet the highest standards, making them suitable for high-performance applications such as military reconnaissance, medical diagnostics, and industrial monitoring. As DLC films continue to evolve, their importance in modern optical technologies will only increase.

GREAT ARTICLE!

Share this article to gain insights from your connections!