RC Telescope Complete Guide | Avantier Technical Overview

The Ritchey-Chrétien telescope (RC telescope) represents a pinnacle in modern telescope design and optical engineering. As a high-precision reflective telescope system, it employs hyperbolic mirrors to minimize optical aberrations such as coma and spherical distortion. This advanced configuration—used in the Hubble Space Telescope and James Webb Space Telescope—demonstrates excellence in space optics, deep-sky imaging, and astronomical instrumentation. Avantier’s expertise in reflective optics, precision polishing, and telescope manufacturing enables the production of RC telescopes optimized for performance, reliability, and scientific discovery.

Table of Contents

- 1.What Is a Ritchey-ChrétienTelescope?

- 2. Ritchey Chrétien Telescope Overview

-

3. The Importance Of RC Telescope In Space Optics

- 3-1. Aberration Correction

- 3-2. Wide Field of View

- 3-3. Compact and Lightweight Design

- 3-4. Thermal Stability in Space Environments

- 3-5. High Reflectivity and Efficiency

- 3-6. Seamless Instrument Integration

- 3-7. Space Applications

- 3-8. Iconic Examples of RC Telescopes

- 3-9. A Telescope Designed For Space’s Challenges

-

4. Ritchey Chrétien Telescope Design Challenges

- 4-1. Optical Fabrication Challenges

- 4-2. Alignment Sensitivity

- 4-3. Thermal Stability

- 4-4. Weight And Size Constraints

- 4-5. Mirror Coating Challenges

- 4-6. Testing And Verification

- 4-7. Manufacturing Lead Time And Cost

- 4-8. Vibration And Deployment Challenges

- 4-9. Instrument Integration

- 4-10. Overcoming Ritchey Chrétien Telescope Design Challenges

- 5. A Guide To Ritchey Chretien Telescopes

- Conclusion: Advancing Optical Innovation Through Ritchey-Chrétien Design

1. What Is a Ritchey-ChrétienTelescope?

The RC (Ritchey-Chrétien) Ritchey-Chrétien space optics is a type of reflecting telescope that belongs to the Cassegrain optical system. It was designed by George Ritchey and Henri Chrétien in 1910, and is named after the initials of both men’s names. The Ritchey Chrétien telescope is a specialized variant of the Cassegrain telescope that uses a primary hyperbolic mirror (primary mirror) and a second hyperbolic mirror (secondary mirror) designed to eliminate off-axis optical errors (coma). The Ritchey Chrétien telescope has a wider field of view and fewer optical errors than traditional reflecting telescopes. This telescope design also eliminates chromatic aberration, which is a natural advantage over refracting telescopes. Avantier applies precision fabrication techniques and extensive testing protocols to ensure consistent optical performance.

Additionally, reflective Ritchey-Chrétien space optics s are usually metal-coated, allowing for the use of wavelengths across both visible and infrared bands. As a result, the vast majority of astronomical telescopes use a reflective design. The Ritchey-Chrétien (RC) telescope design is well-known for its application in the Hubble Space Telescope, where it has enabled groundbreaking observations of the cosmos.

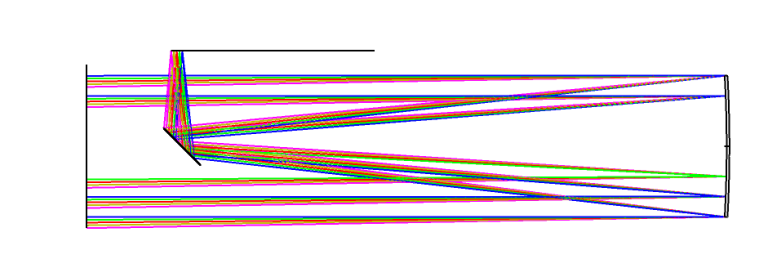

1-1. Reflecting Telescope

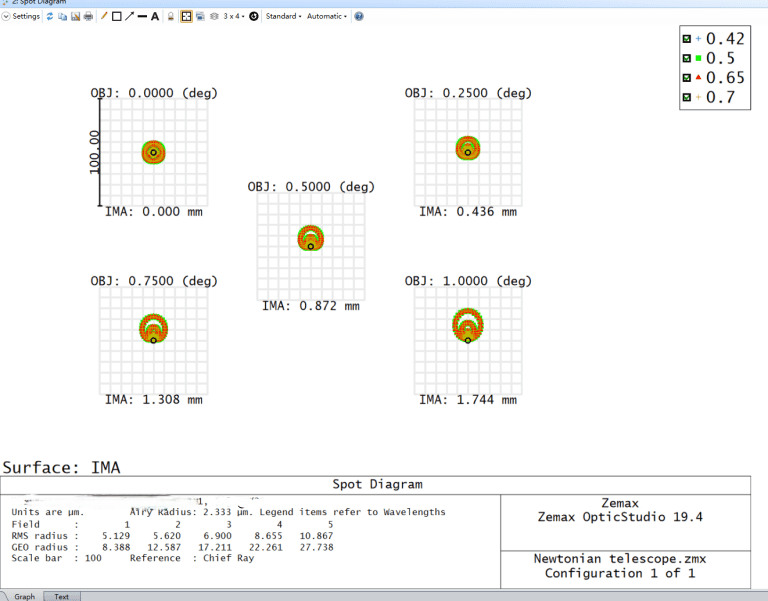

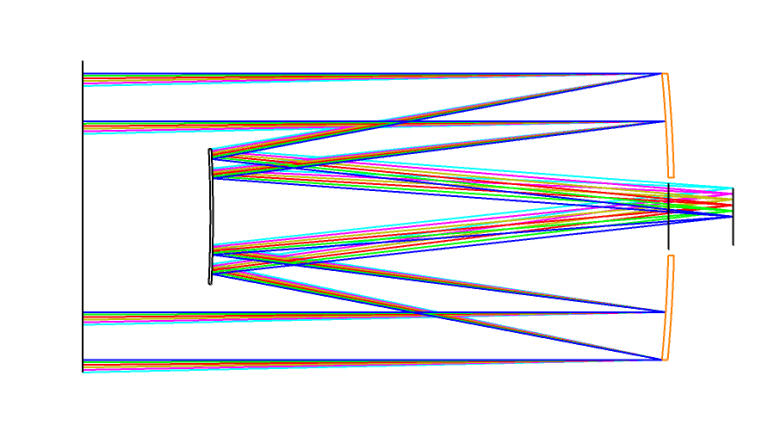

Newton’s first reflective telescope employed a spherical mirror, marking a fundamental step in the development of modern optical systems. However, spherical mirrors inherently produce spherical aberration, an optical distortion that increases roughly with the cube of the aperture diameter. As the aperture grows, light rays reflected near the mirror’s edge converge at different points than those near its center, reducing image sharpness and limiting both the F-number and achievable image quality. Because of their rotational symmetry, spherical mirrors provide relatively uniform illumination across the field of view, making them suitable for small-aperture systems or applications with modest resolution requirements. Yet for high-precision imaging, their aberration becomes a critical limitation. The 2D optical path diagram below illustrates how light rays reflect within this configuration. Parallel rays entering the telescope are reflected by the concave spherical mirror toward the focal region; however, instead of meeting at a single focus, they intersect at slightly different axial positions. The diagram makes clear how marginal rays (from the outer regions of the mirror) and paraxial rays (near the optical axis) focus differently, producing a blurred image and demonstrating the essence of spherical aberration. The spot diagram for a Newtonian telescope with F = 8.3 and a focal length of 100 mm further quantifies this effect. Each “spot” represents where light from a point source lands on the image plane; the dispersed pattern shows that image quality across the field is not ideal, even for moderate apertures.

Although mechanically simple, this single-mirror system cannot deliver the resolution demanded by advanced astronomy. These limitations inspired the evolution of multi-mirror configurations—most notably the Cassegrain and Ritchey-Chrétien designs—that dramatically improved optical performance through more sophisticated geometries.

1-2. Cassegrain System & RC Telescope

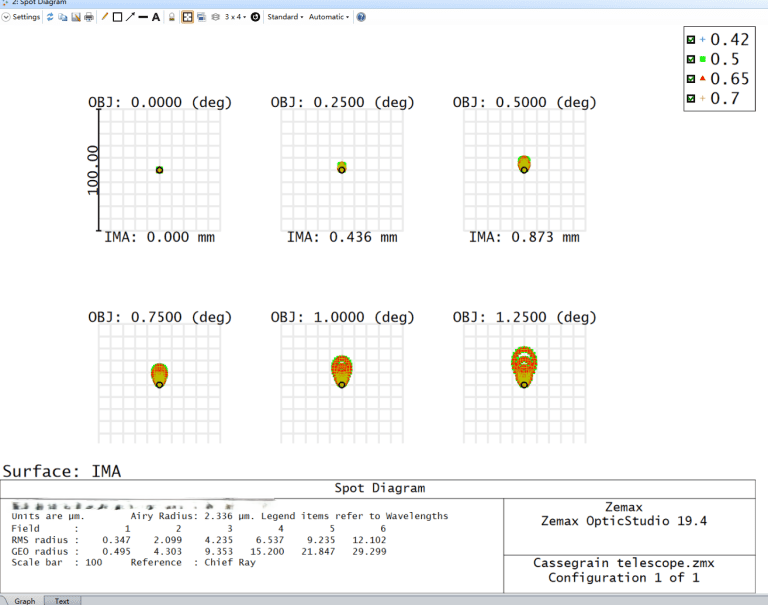

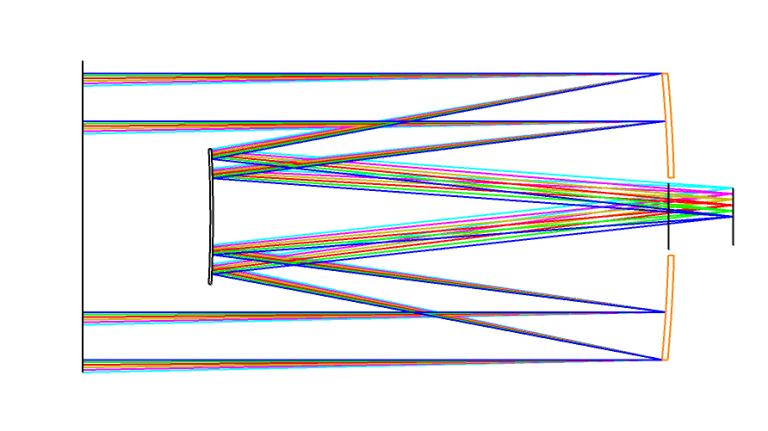

To address the image degradation caused by spherical aberration, optical designers introduced a convex secondary mirror positioned along the optical axis of a concave primary. This configuration—known as the Cassegrain system—shortens the overall telescope length while offering more degrees of freedom for optical correction. In this setup, the secondary mirror partially blocks the incoming beam, an effect measured by the light-blocking coefficient, defined as the ratio of the secondary mirror’s diameter to that of the primary beam. A higher blocking coefficient leads to greater energy loss and reduced image contrast, so selecting an appropriate ratio is critical to maintaining optical efficiency. Traditional Cassegrain telescopes often employ a paraboloidal primary mirror to eliminate spherical aberration on-axis. However, the single axis of symmetry means that when light rays enter at small angles, off-axis aberrations—particularly coma, as well as astigmatism and field curvature—emerge. These effects worsen as the field of view increases, limiting image uniformity. The diagram below demonstrates the spot pattern of a Cassegrain telescope (F = 100 mm, F = 8.3), which achieves diffraction-limited resolution on-axis but shows pronounced coma toward the edges.

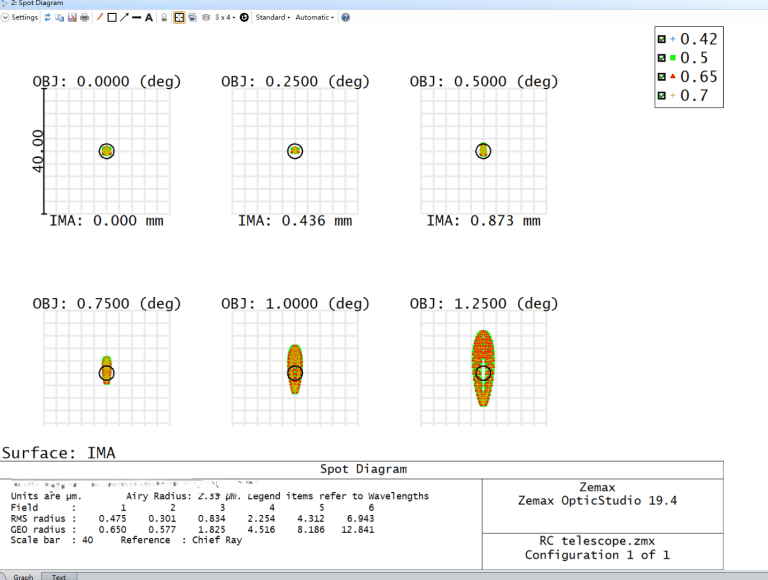

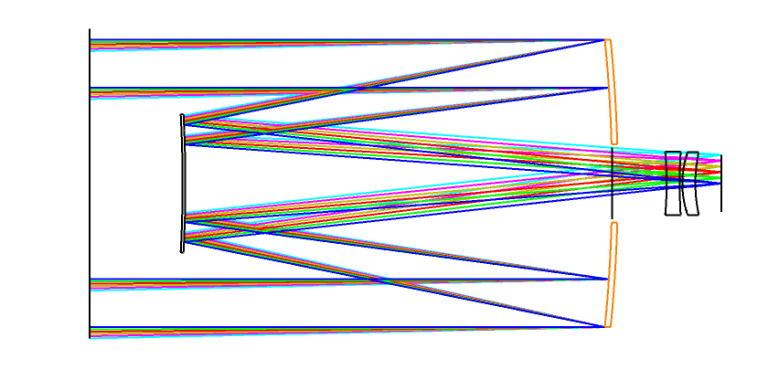

To overcome these off-axis limitations, George Ritchey and Henri Chrétien replaced the paraboloidal and spherical elements with hyperbolic primary and secondary mirrors, creating the Ritchey-Chrétien (RC) design. This configuration eliminates both coma and spherical aberration, providing a nearly uniform image across the field. While field curvature and astigmatism remain, their impact is far less significant, and further correction is possible with field-flattening lenses.

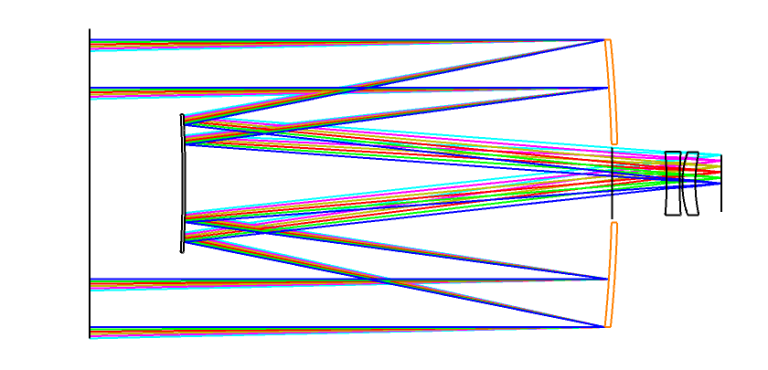

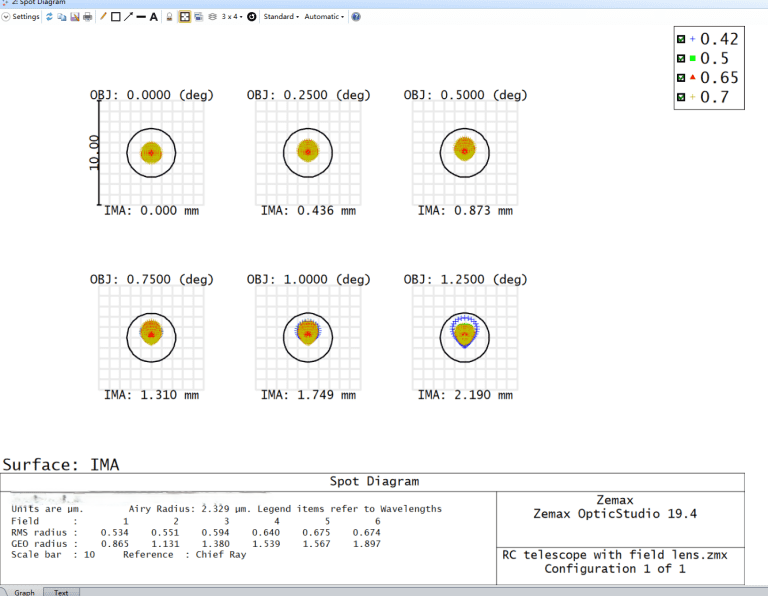

The diagram below compares the RC system’s optical performance at F = 100 mm, F = 8.3, demonstrating significantly improved off-axis image quality compared to the classical Cassegrain design.

For applications requiring an especially wide and flat field of view, an additional field-correcting lens group can be positioned near the image plane to mitigate residual curvature and astigmatism. With such correction, the image quality remains excellent across a 1.25° half-field.

1-3. RC Telescope Summary

The Ritchey-Chrétien telescope is a reflecting optical system that employs hyperbolic primary and secondary mirrors to correct coma and spherical aberration while maintaining diffraction-limited resolution on-axis. Compared with other Cassegrain-type systems, RC telescopes typically operate at F-numbers between F/6 and F/10, offering a practical balance between light-gathering power and image clarity. Image quality across the field can be further enhanced by incorporating field-correcting lenses, making RC systems particularly well-suited for wide-field imaging, astrophotography, and space-based observation. Despite its advantages, the RC design introduces certain trade-offs:- The central obstruction caused by the secondary mirror slightly reduces contrast and light throughput.

- Alignment sensitivity is high—small deviations between the mirror axes can introduce new aberrations, requiring precise assembly and maintenance.

- The fabrication of hyperbolic surfaces demands specialized tooling and meticulous testing, increasing manufacturing complexity and cost relative to spherical systems.

2. Ritchey Chrétien Telescope Overview

The Ritchey-Chrétien (RC) space optics is a highly specialized variant of the Cassegrain reflector telescope, designed to deliver superior optical precision and clarity. Its advanced design minimizes optical aberrations, making it a preferred choice for both space-based and ground-based astronomy. With its capability to support cutting-edge imaging and spectroscopy, the Ritchey-Chrétien (RC) telescope has become an integral tool for exploring the universe.

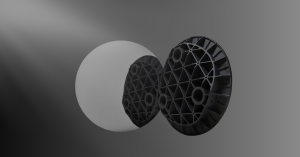

2- 1. Optical Design

The Ritchey-Chrétien optical design utilizes two carefully shaped hyperbolic mirrors:- Primary Mirror: Concave, collects and directs incoming light.

- Secondary Mirror: Convex, reflects light back through a central aperture to the focal plane.

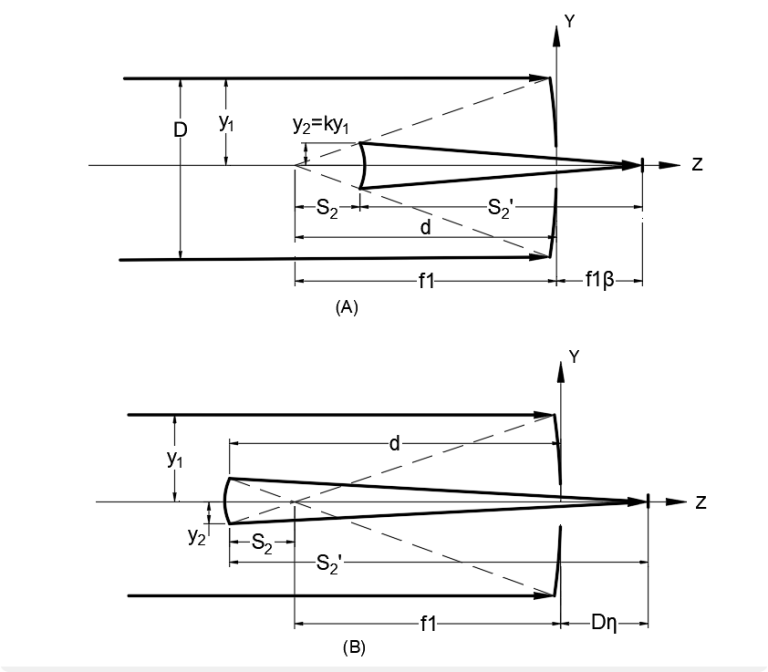

a: RC design with a convex secondary mirror

b: Gregorian Ritchey-Chrétien space optics design with a concave secondary mirror. As shown, this design results in a longer distance between the primary and secondary mirrors.

2-2. Optical Performance

The RC telescope achieves near-diffraction-limited performance, meaning its image sharpness is limited primarily by the wavelength of light rather than optical imperfections. Key optical advantages include:- Coma Elimination: Stars remain point-like even near the field edges.

- Spherical Aberration Correction: Ensures uniform image focus.

- Minimized Astigmatism and Field Curvature: Produces flatter imaging planes for modern sensors.

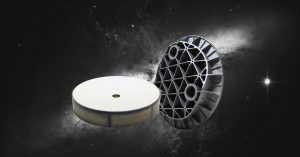

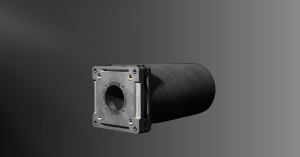

2-3. Mechanical Design for Space Applications

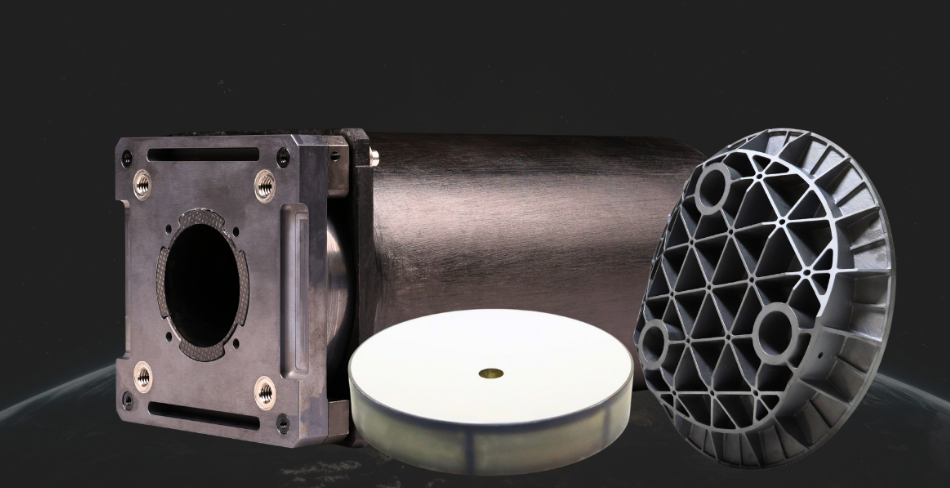

Space telescopes face extreme environmental and structural demands. RC designs address these through:- Lightweight Mirrors: Materials like beryllium, silicon carbide, or ultra-low-expansion glass minimize mass and thermal distortion.

- Rigid Mirror Supports: Precision trusses maintain alignment during launch and operation.

- Active Optics Systems: Sensors and actuators perform fine adjustments to preserve focus and image quality in microgravity.

2-4. Instrumentation And Integration

The RC architecture is adaptable to a wide range of instruments:- Imaging Systems: CCD and infrared detectors capture high-resolution data.

- Spectrographs: Analyze the spectral composition of light for chemical and physical insights.

- Coronagraphs and Polarimeters: Enable specialized studies like exoplanet detection or polarization measurements.

- Cryogenic Cooling: Infrared applications use cooled detectors to reduce thermal noise and enhance sensitivity.

2-5. Space-Specific Advantages

The RC configuration offers unique benefits for space missions:- Aberration-free wide fields, ideal for galaxy surveys and star-cluster imaging.

- Scalable aperture sizes, supporting telescopes from small research units to flagship observatories like JWST.

- Broad wavelength compatibility, from ultraviolet to infrared, is enabled by optimized coatings and detectors.

- Compact structure, minimizing launch weight and volume while maintaining optical performance.

2-6. Examples Of Advanced Space Rc Telescopes

- Hubble Space Telescope (HST): 2.4 m aperture, f/24 system; provides high-resolution UV and visible imaging.

- James Webb Space Telescope (JWST): 6.5 m segmented beryllium mirror, f/20; optimized for infrared astronomy.

- Other Missions: Many modern observatories, both ground- and space-based, employ RC principles to achieve superior optical correction and stability.

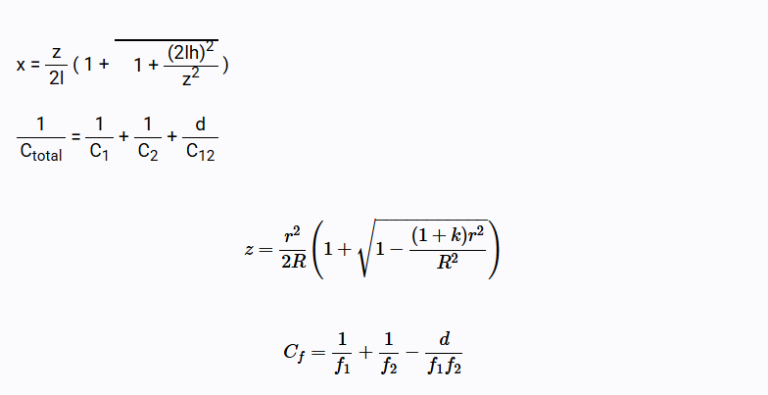

2-7. Mathematical Framework

The performance of RC telescopes can be modeled through wavefront error analysis, which quantifies deviations from the ideal optical surface. By optimizing the mirror parameters and alignment tolerances, designers minimize residual aberrations and achieve near-perfect imaging fidelity.

Overall, the Ritchey-Chrétien space optics represents a critical advancement in optical design, providing astronomers with the capability to observe and study celestial objects with unprecedented clarity and detail.

3. The Importance Of RC Telescope In Space Optics

After addressing optical precision, another major advantage of the RC telescope lies in its compact form factor and adaptability for space missions. In the realm of space exploration, precision is everything. The Ritchey-Chrétien (RC) telescope has become a cornerstone for astronomical instruments, offering exceptional performance through its advanced optical design. Here’s why the Ritchey-Chrétien (RC) telescope is pivotal in space optics and what sets it apart.

Astrophotography and space-based observations demand unparalleled clarity. The Ritchey-Chrétien (RC) space optics excels in eliminating optical aberrations:

3-1. Aberration Correction

- Spherical Aberration: Ritchey-Chrétien (RC) telescopes are designed to eliminate spherical aberration through the use of hyperbolic primary and secondary mirrors. This ensures that light from celestial objects converges at a single focal point, enhancing image sharpness and overall imaging precision.

- Coma Correction: Unlike simpler Ritchey-Chrétien space optics designs, such as Newtonian or Cassegrain telescope systems, the RC configuration corrects for coma and which causes off-axis stars to appear distorted or elongated. This is crucial for capturing accurate and uniform data over a wide field of view.

- Astigmatism Reduction: Ritchey-Chrétien (RC) space optics s are designed to minimize astigmatism, further improving the focus and clarity of images across the entire field.

3-2. Wide Field of View

- Galaxy Mapping: Capturing high-resolution images of galaxies across the universe.

- Supernova Detection: Observing transient celestial events.

- Dark Matter Exploration: Studying cosmic structures influenced by dark matter.

3-3. Compact and Lightweight Design

Space missions are constrained by size and weight due to launch vehicle limitations. The RC design offers a shorter optical tube length compared to other high-performance optical systems, reducing the Ritchey-Chrétien space optics ’s overall size and weight while maintaining high resolution and performance.3-4. Thermal Stability in Space Environments

Operating under extreme and variable temperatures, space-based Ritchey-Chrétien space optics s require robust designs. The Ritchey-Chrétien (RC) telescope remains thermally stable, minimizing alignment shifts and reducing reliance on complex active adjustment systems. This stability ensures reliable, long-term performance.3-5. High Reflectivity and Efficiency

Ritchey-Chrétien (RC) space optics s use advanced reflective coatings, such as aluminum or enhanced silver, to maximize light collection. This efficiency is crucial for studying:- Exoplanets: Observing faint planetary systems around distant stars.

- Distant Galaxies: Investigating the universe’s most remote structures.

- Cosmic Background Radiation: Analyzing the remnants of the Big Bang.

3-6. Seamless Instrument Integration

Flexibility is key for multi-purpose missions. The Ritchey-Chrétien (RC) space optics ’s design allows for easy attachment of advanced instruments such as spectrographs, cameras, and coronagraphs, enabling a wide range of observational techniques.3-7. Space Applications

Ritchey-Chrétien (RC) space optics s play an indispensable role in various astronomical missions:- Deep Space Exploration: Imaging distant galaxies and nebulae with unmatched resolution.

- Exoplanet Research: Supporting precise measurements for photometry and spectroscopy.

- Astrophysical Phenomena: Studying black holes, gravitational waves, and cosmic microwave background radiation.

3-8. Iconic Examples of RC Telescopes

- Hubble Space Telescope: An RC design that has provided some of the most iconic images of the universe with minimal optical distortions.

- James Webb Space Telescope (JWST): Employing principles of the RC system with deployable optics, it observes infrared wavelengths, pushing the boundaries of what’s possible in space observation.

3-9. A Telescope Designed For Space’s Challenges

The Ritchey-Chrétien space optics ‘ ability to deliver aberration-free, high resolution imaging in a compact and thermally stable form makes it essential for space missions. Whether mapping the cosmos, detecting exoplanets, or exploring astrophysical phenomena, the Ritchey-Chrétien (RC) telescope continues to be a driving force in advancing our understanding of the universe. At Avantier, our exceptional engineering knowledge and decades of experience enable us to produce high precision optics, such as SiC mirrors and off-axis parabolic mirrors, for space optics. We provide customized solutions tailored to the unique demands of space-based applications. With top-notch techniques in designing and manufacturing optical lens assemblies, we are committed to supporting groundbreaking advancements in space exploration.4. Ritchey Chrétien Telescope Design Challenges

The Ritchey-Chrétien (RC) space optics , a specialized variant of the Cassegrain optical system, is renowned for its advanced design. With hyperbolic primary mirrors and secondary mirrors, this telescope eliminates off-axis optical errors (coma) and chromatic aberration, offering a wide field of view and exceptional image quality. However, designing and manufacturing Ritchey-Chrétien (RC) telescopes poses significant challenges, particularly for space applications. This article explores these challenges and the innovative solutions employed to overcome them.

4-1. Optical Fabrication Challenges

The Challenge:- Hyperbolic Surfaces: Ritchey-Chrétien (RC) space optics s require precisely fabricated hyperbolic mirrors, demanding extreme precision.

- Surface Accuracy: Achieving nanometer-level accuracy is critical for diffraction-limited performance.

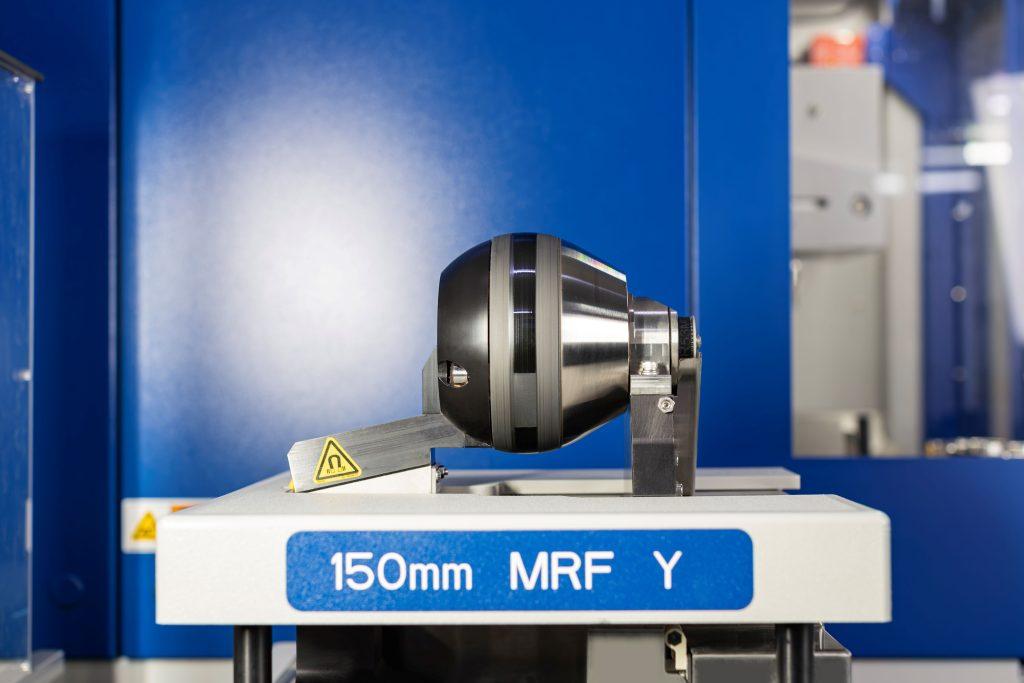

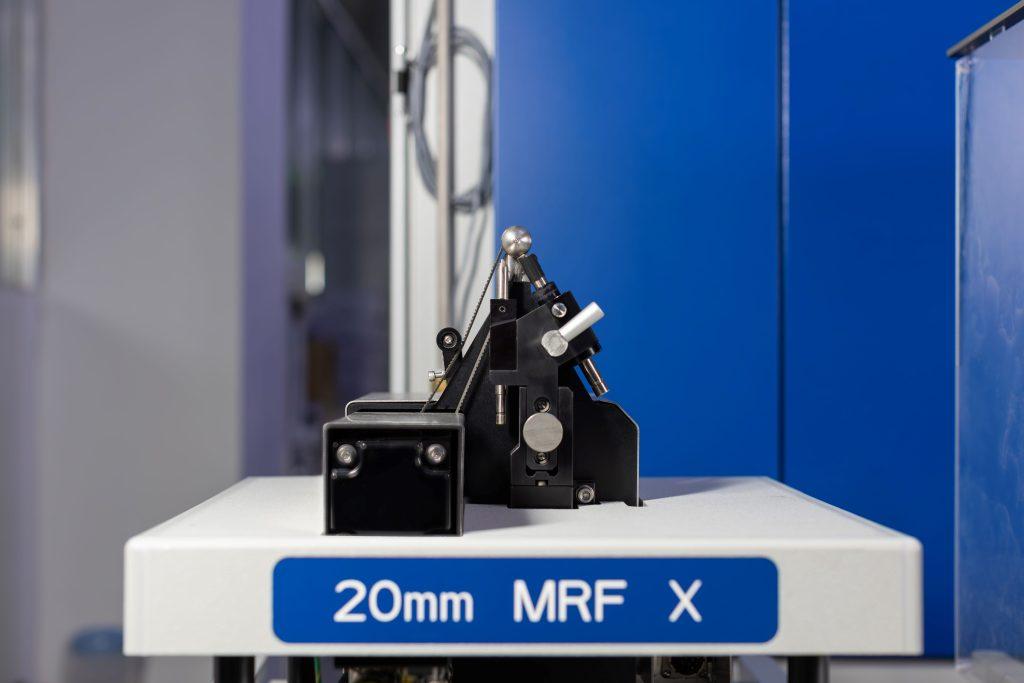

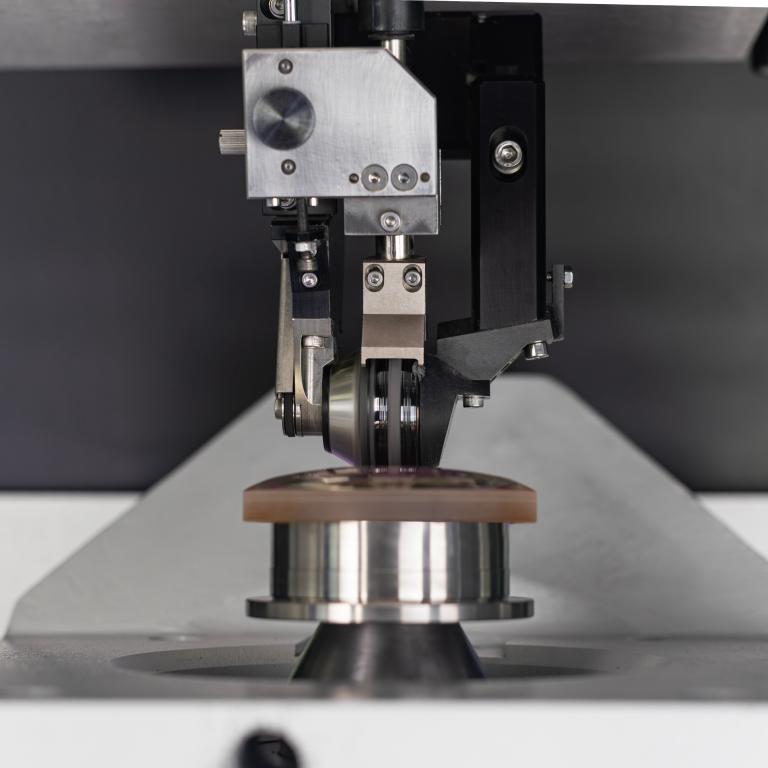

- Advanced Polishing Techniques: Methods like computer-controlled optical surfacing (CCOS), ion-beam figuring, and magnetorheological finishing (MRF) achieve the required precision.

- Interferometric Testing: High-resolution interferometry ensures precise measurements and corrections during production.

- Replication Processes: For smaller Ritchey-Chrétien space optics s, replication techniques enable cost-effective fabrication of hyperbolic surfaces.

4-2. Alignment Sensitivity

The Challenge:- Misalignments degrade image quality, leading to issues such as coma and astigmatism.

- Ritchey-Chrétien (RC) space optics s are especially prone to angular and positional inaccuracies.

- Active Optics: Sensors and actuators enable real-time alignment adjustments.

- Kinematic Mounts: These mounts ensure consistent and repeatable mirror positioning.

- Alignment Jigs and Fixtures: Precise tools minimize alignment errors during assembly and testing.

4-3. Thermal Stability

The Challenge:- Temperature fluctuations may lead to thermal expansion or contraction, which misaligns optical components and degrades performance.

- Low-Expansion Materials: Materials like Zerodur, ULE glass, silicon carbide, or beryllium minimize thermal effects.

- Thermal Shielding: Multi-layer insulation (MLI) or sunshields help stabilize internal temperatures.

- Active Thermal Control: Heaters and coolers maintain a consistent thermal environment.

4-4. Weight And Size Constraints

The Challenge:- Launch vehicle payload limitations restrict Ritchey-Chrétien RC space optics size and weight.

- Large mirrors increase structural demands without sacrificing rigidity.

- Lightweight Mirrors: Honeycomb or sandwich designs, silicon carbide (sic) mirrors, and hollow-core mirrors balance weight and stiffness.

- Deployable Optics: Foldable structures or segmented mirrors ensure compactness for launch.

- Topology Optimization: Computational design techniques reduce mass while maintaining structural integrity.

4-5. Mirror Coating Challenges

The Challenge:- Reflective coatings must withstand space radiation, contamination, and micrometeoroid impacts while maintaining optimal performance.

- Enhanced Coatings: Protected silver for visible/infrared wavelengths and specialized coatings for UV applications improve performance.

- Contamination Control: Cleanroom production and low-outgassing designs ensure coating longevity.

- Redundant Coating Layers: Multi-layer coatings improve durability and extend mirror lifespan.

4-6. Testing And Verification

The Challenge:- Gravity distortion complicates terrestrial testing of large Ritchey-Chrétien RC space optics s.

- Launch vibrations pose risks to delicate components.

- Finite Element Analysis (FEA): Simulations predict performance under space conditions.

- Gravity Compensation Testing: Counterweights or vertical setups simulate microgravity conditions.

- Environmental Chambers: Vacuum and cryogenic tests replicate space environments.

4-7. Manufacturing Lead Time And Cost

The Challenge:- Stringent precision requirements lead to long production cycles and high costs.

- Modular Design: Standardized components reduce custom fabrication.

- Automation: Robotic polishing and assembly improve efficiency.

- Cost Sharing: Collaborations with international partners lower expenses and leverage expertise.

4-8. Vibration And Deployment Challenges

The Challenge:- Launch vibrations and deployment mechanisms pose risks to delicate components.

- Shock-Absorbing Systems: Damping mechanisms protect sensitive parts during launch.

- Rigorous Deployment Testing: Comprehensive testing ensures reliable operation in space.

- Redundant Systems: Backup mechanisms reduce the risk of deployment failure.

4-9. Instrument Integration

The Challenge:- Scientific instruments require precise alignment with the focal plane for optimal performance.

- Precision Positioning Systems: Piezoelectric actuators or hexapods allow fine adjustments.

- Corrective Optics: Field flatteners and correctors optimize wide-field imaging.

4-10. Overcoming Ritchey Chrétien Telescope Design Challenges

- Advanced Materials: Employ low-expansion, lightweight materials and durable coatings.

- Precision Manufacturing: Leverage latest fabrication and testing technologies.

- Active Systems: Incorporate active correction mechanisms for real-time alignment and thermal control.

- Rigorous Testing: Simulate and validate performance under space-like conditions.

- Cost Efficiency: Modular designs and automation reduce production time and expense.

5. A Guide To Ritchey Chretien Telescopes

Ritchey-Chrétien (RC) space optics s are advanced reflecting telescopes renowned for their exceptional image quality and minimized optical aberrations. Their ability to produce high-quality images with minimal distortion, combined with a compact design and fewer optical elements, makes them ideal for both space applications and large aperture observations. Here’s an overview of what makes Ritchey-Chrétien (RC) telescopes unique, their design advantages, and why you should consider using one.

5-1. Design And Optical Features

- Reflective Design: Ritchey-Chrétien (RC) space optics s use a reflective mirror system that accommodates a wider spectrum range and eliminates chromatic aberration, unlike refractive designs. This capability is especially beneficial for multi-spectrum imaging and space communication applications.

- Cassegrain Focus Design: The Ritchey-Chrétien (RC) space optics employs two hyperbolic mirrors: a concave hyperbolic primary mirror and a convex hyperbolic secondary mirror. This configuration, a variant of the Cassegrain reflector, creates a more compact telescope with a longer effective focal length, making it ideal for observing distant celestial objects and space applications.

- Compact Size: The Ritchey-Chrétien (RC) space optics achieves its compact design by positioning the convex secondary mirror inside the primary focus.

- Minimized Optical Aberrations: Ritchey-Chrétien (RC) space optics s are engineered to significantly reduce optical aberrations, such as coma and spherical aberration. This design ensures sharp focus on a flat sensor or film plane, delivering high-contrast images across a wide field of view. Such precision is ideal for capturing detailed features of deep-sky objects like galaxies and nebulae. In space communication, it also aids in effective long-distance communication.

- Field-Correcting Elements: Many Ritchey-Chrétien (RC) space optics s include additional field-correcting optics to enhance image quality. These optics ensure sharpness throughout the field and are compactly positioned near the imaging plane, maintaining a streamlined design.

5-2. Manufacturing And Cost Considerations

- Primary Mirror Testing: Testing the hyperbolic concave primary mirror requires a large reference mirror or a Computer Generated Hologram (CGH), adding complexity and cost.

- Secondary Mirror Testing: Testing the hyperbolic convex secondary mirror demands a reference mirror larger than itself. Accurate evaluation cannot rely solely on CGH unless the mirror size is very small.

- Alignment Challenges: Minimizing coma requires precise alignment of the two mirrors across five degrees of freedom, presenting significant structural design challenges.

5-3. Avantier’s RC Telescope Capabilities

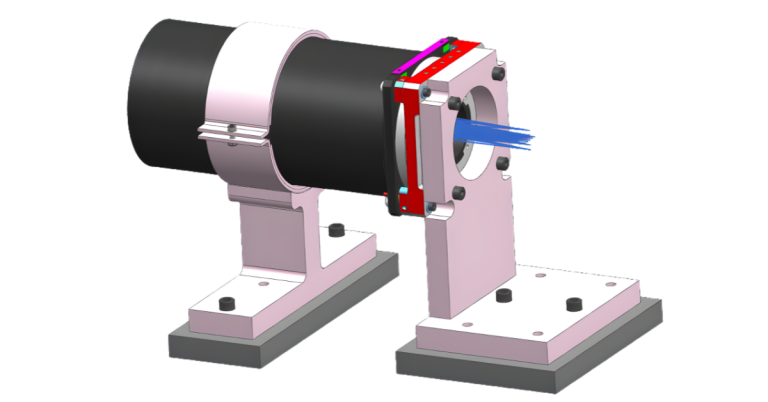

Avantier provides comprehensive support for Ritchey-Chrétien telescope development, from design to full production. The company’s capabilities include:- Custom Optical Design: On-axis and off-axis RC configurations tailored to research or industrial needs.

- Precision Fabrication: In-house diamond turning, computer-controlled polishing, and interferometric testing ensure nanometer-level accuracy.

- Material Expertise: Production of mirrors and structures in glass, Zerodur, aluminum, and silicon carbide, up to one meter in diameter.

- Thermal Management Systems: Engineered to maintain alignment and optical stability across temperature variations.

- Integration and Validation: Optomechanical assemblies include built-in alignment features, simplifying final integration and verification.

Conclusion: Advancing Optical Innovation Through Ritchey-Chrétien Design

The Ritchey-Chrétien (RC) telescope remains the cornerstone of modern space optics and precision astronomy. By leveraging advanced materials, hyperbolic mirror designs, and active optical alignment systems, RC telescopes achieve unmatched imaging performance. The Ritchey-Chrétien telescope remains a benchmark of optical innovation, enabling scientists to explore the universe with ever-increasing clarity. Companies like Avantier continue to refine and apply these principles to modern research and space missions.

GREAT ARTICLE!

Share this article to gain insights from your connections!