Executive Summary

- This technical analysis explores the critical role of optical coating technology in modern photonics, focusing on the transition from standard interference theory to high-performance industrial applications.

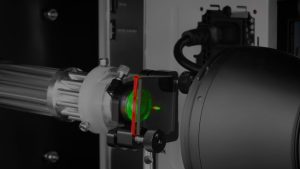

- The report highlights Avantier’s core capabilities in controlling light through Ion-Assisted Deposition (IAD) and Physical Vapor Deposition (PVD).

- Key highlights include the engineering of film packing densities (0.85–0.95) to eliminate spectral drift, the achievement of reflectivity thresholds exceeding 99.9% for dielectric mirrors, and the development of multi-band anti-reflection stacks that reduce loss to ≤0.5%.

- By integrating advanced vacuum evaporation and magnetron sputtering, the study demonstrates how customized coating solutions address the rigorous demands of AR/VR, aerospace, and high-power laser systems.

Optical coatings are the silent enablers of modern photonics. By depositing functional thin films via precise physical or chemical methods, we manipulate the fundamental properties of light—reflection, transmission, polarization, and spectral distribution.

From the high-clarity requirements of consumer electronics and AR/VR optics to the extreme durability needed for aerospace and high-power laser systems, our coating solutions provide the critical performance edge.

I. The Physics of Precision: Controlling the Wavefront

The foundation of our technology lies in the interference of light waves. By engineering the refractive index (n), physical thickness (d), and layer count, we create constructive or destructive interference to steer light intensity with surgical precision.Key Performance Drivers:

- Refractive Index & Packing Density: We maintain film packing densities between 0.85 and 0.95. Low density often leads to “spectral drift” as water vapor infiltrates the film. By utilizing Ion-Assisted Deposition (IAD), we stabilize the refractive index, ensuring performance remains constant regardless of humidity.

- Systemic Transmittance Gains: Through strategic layer stacks, we transform surface physics. For example, a specialized coating on a high-index glass substrate (n=1.8) can elevate transmittance from a baseline of 91.8% to over 95.2%.

II. Full-Spectrum Solutions: Tailored for Multi-Scenario Demands

We provide a comprehensive portfolio of coatings, each optimized for specific spectral and environmental challenges.

1. Anti-Reflection (AR) Coatings

Standard glass reflects 4–5% of incident light per surface. Our multilayer AR stacks, utilizing alternating layers of SiO2 and ZrO2, reduce reflectivity to ≤0.5% across visible and NIR bands.- Applications: AR/VR displays, high-end camera lenses, and high-efficiency photovoltaic modules.

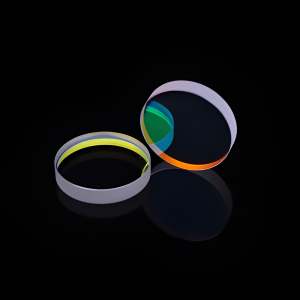

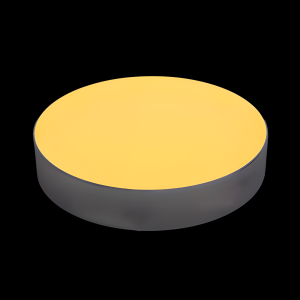

2. High-Performance Reflective Films

We offer both metallic and dielectric solutions depending on the bandwidth and reflectivity requirements:- Metallic Films: Economic Aluminum (85–90% R), high-visibility Silver (enhanced with dielectric protection for oxidation resistance), and Gold (98% R) for specialized Infrared (IR) detection.

- Dielectric Mirrors: Leveraging multi-layer interference to achieve >99.9% reflectivity for laser resonators and precision interferometry.

3. Spectral Filtering & Beam Splitting

- Interference Filters: We manufacture Bandpass, Long-pass, and Short-pass filters with extreme edge steepness and narrow bandwidths for Raman spectroscopy and imaging.

- Beam Splitters: Our Neutral Density (ND) filters and dichroic splitters enable precise light distribution (e.g., 1:1 or 1:3 ratios) with negligible chromatic aberration.

4. Specialized Functional Coatings

- ITO Conductive Coatings: High-transmittance, low-resistance films for touch panels and EMI shielding.

- Cold Light Coatings: Designed to reflect visible light while transmitting IR heat, essential for stage lighting and thermal management in automotive glass.

III. Advanced Manufacturing & Quality Ecosystem

Our facility utilizes state-of-the-art Physical Vapor Deposition (PVD) techniques to ensure uniformity across complex geometries.

Process |

Strength |

Best For |

E-Beam Evaporation |

High purity; handles high-melting-point materials (SiO2, ZrO2). |

Precision lab optics & small batches. |

Magnetron Sputtering |

Exceptional adhesion and film density via dual-field confinement. |

Industrial mass production & ruggedized coatings. |

Ion Plating |

Combines evaporation with high-energy bombardment for maximum hardness. |

Extreme environments and military-grade specs. |

Rigorous Quality Assurance

Precision is verified through an integrated monitoring and testing suite:- In-situ Monitoring: Real-time quartz crystal and optical thickness monitoring for atomic-layer control.

- Environmental Validation: Every batch undergoes rigorous testing for Adhesion (Tape Test), Abrasion Resistance, and Thermal/Humidity Cycling to ensure long-term field reliability.

IV. Partnering for the Future

At Avantier, we don’t just provide coatings; we provide Optical Performance Optimization. From initial design support and prototyping to high-volume mass production, we are committed to pushing the boundaries of what is possible with light.

Whether you require higher laser damage thresholds or a broader spectral range, our engineering team is ready to develop your custom solution.

GREAT ARTICLE!

Share this article to gain insights from your connections!