Key Takeaways

- Off-axis innovation: OAP mirrors eliminate central obstruction and aberration, enabling diffraction-limited focusing and ultra-smooth beam collimation.

- Precision fabrication: Avantier achieves λ/20 to λ/50 surface accuracy and <0.2 nm surface roughness through advanced diamond turning, magnetorheological, and ion beam polishing.

- Material optimization: Tailored substrates—from oxygen-free copper to silicon carbide and CFRP—ensure thermal stability and low weight across diverse environments.

- High-performance coatings: Custom multilayer coatings deliver high reflectivity and durability across UV, visible, and IR spectra.

- Broad applications: From EUV lithography and quantum optics to satellite telescopes and ophthalmic OCT, OAP mirrors support next-generation optical systems.

- Future direction: Integration of large-aperture mirrors, AI-assisted finishing, and novel materials (diamond, AlN) will define the next era of high-precision optics.

Overview

Off-axis parabolic (OAP) mirrors are redefining the limits of optical performance across laser systems, semiconductor lithography, medical imaging, and deep-space exploration. By eliminating central obstruction and reducing aberration, OAP mirrors provide unparalleled control over light — enabling diffraction-limited focusing, nanoscale beam shaping, and ultra-high signal-to-noise imaging.

This article introduces the principles behind OAP optics, explores Avantier’s advanced fabrication process chain, and highlights the mirrors’ wide-ranging applications — from chip manufacturing to astronomical telescopes.

1. Principles of Off-Axis Parabolic (OAP) Mirrors

1.1 Off-Axis Optical Geometry

An off-axis parabolic mirror is derived from a segment of a complete parabolic reflector. The parabolic geometry ensures that:- Light rays parallel to the optical axis are reflected precisely to the focal point.

- Rays emitted from the focal point reflect as perfectly parallel light.

- Eliminates central obstruction: Maximizes light throughput and energy utilization.

- Zero spherical aberration: Preserves ideal parabolic focusing across wavelengths.

- Flexible design: Off-axis distance and focal length can be customized for specific optical layouts.

1.2 Defining Parameters

Each OAP mirror is defined by several structural parameters:- Off-Axis Distance: The perpendicular offset between the paraboloid’s vertex and the optical axis — determines beam offset direction and angle.

- Focal Length: Distance from the vertex to the focal point — affects spot size and collimation.

- Effective Aperture: The usable reflective area — defines the maximum beam diameter and capture efficiency.

2. Advanced Fabrication: From Material to Mirror

Avantier’s strength lies in an end-to-end manufacturing process that integrates materials science, precision machining, metrology, and coating engineering to achieve extreme accuracy and stability.

2.1 Materials Tailored for Application

Avantier selects substrates according to each optical system’s environmental and performance requirements.

Material Type |

Representative Materials |

Core Features |

Typical Applications |

Metallic |

Oxygen-free copper, aluminum alloy |

Excellent thermal conductivity, high heat load tolerance |

High-power laser systems |

Glass |

Fused silica (quartz), BK7 |

Low thermal expansion, ultra-smooth finish |

Astronomical imaging, medical optics |

Ceramic |

Silicon carbide (SiC) |

Lightweight, high stiffness, stable under extreme conditions |

Space telescopes, remote sensing |

Composite |

Carbon fiber reinforced polymer (CFRP) |

Near-zero expansion, ultra-lightweight |

Next-generation astronomical instruments |

2.2 Precision Machining and Surface Finishing

Avantier’s OAP mirrors are produced through a multi-stage precision process designed to minimize deformation and achieve sub-nanometer surface quality.- Rough Shaping:

- Metals: Forging followed by stress-relief heat treatment to stabilize the internal structure.

- Glass/Ceramics: High-temperature molding with initial contour deviation below 0.1 mm.

- Semi-Finishing:

- CNC milling and diamond grinding bring contour deviations within the micron range.

- Ultra-Precision Machining:

- Single-Point Diamond Turning (SPDT) for micrometer-level form accuracy.

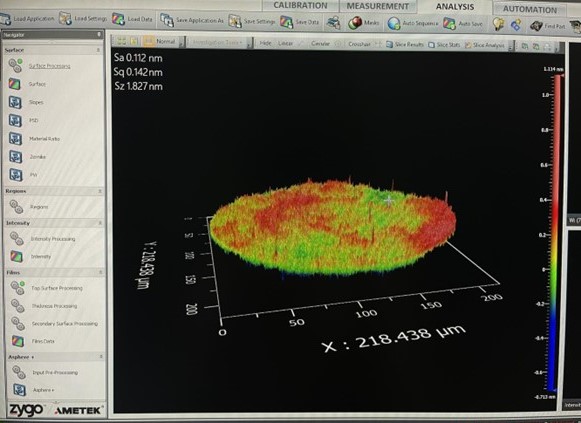

- Magnetorheological Finishing (MRF) and Ion Beam Polishing (IBP) for ultimate refinement — achieving:

- Surface figure accuracy: λ/20 to λ/50 (λ = 632.8 nm)

- Surface roughness: Ra < 0.2 nm

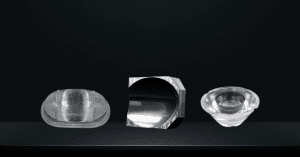

2.3 Coating Engineering

Avantier offers fully customized coating solutions across spectral ranges:

- Visible: High-reflectivity silver or aluminum coatings (R > 85%)

- Infrared: Broadband transmittance coatings for thermal imaging systems

- Ultraviolet/EUV: Multilayer thin films (e.g., molybdenum-silicon) with >70% reflectivity at 13.5 nm

- Durability Enhancements: Protective overcoats for humidity, oxidation, and abrasion resistance

These coatings ensure optical stability and extended lifetime even under high-energy or space conditions.

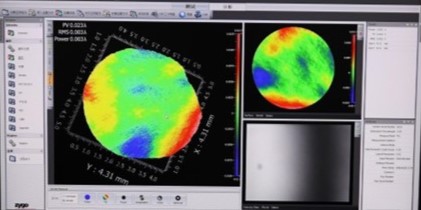

3. Performance Metrics and Quality Assurance

3.1 Optical Performance

Avantier’s mirrors are rigorously tested to ensure compliance with demanding optical standards:- Surface Figure Error (SFE): ≤ λ/10 standard; ≤ λ/50 for EUV or deep-space systems.

- Surface Roughness (Ra): < 0.5 nm (metal), < 0.1 nm (glass).

- Reflectivity: 85–98% (visible/IR), 70%+ (EUV).

- Focal Length Tolerance: Typically ±0.1% to ±1%; <±0.5% for precision laser focusing.

3.2 Mechanical and Environmental Reliability

Designed for reliability across extreme conditions:- Aperture Range: 1 mm to 1 m

- Off-Axis Distance Tolerance: < ±0.1 mm

- Operating Temperature: –40°C to +85°C (industrial), –196°C to +120°C (space)

- Humidity Tolerance: 0–95% (non-condensing)

- Vibration Resistance: > 1000 m/s² (aerospace-qualified)

4. Application Domains

4.1 Laser Processing and Photonics

In laser-based manufacturing, OAP mirrors enable micron- and nanometer-scale focusing precision:

- Laser Cutting & Welding: Focus CO₂ or fiber lasers to <10 µm spots for high-quality edges and minimal thermal damage.

- Laser Marking: Low-aberration optics achieve >500 dpi resolution on microelectronic components.

- Laser Fusion: Used in Inertial Confinement Fusion (ICF) systems to focus multi-beam high-power lasers onto fusion targets, requiring λ/20 or better surface accuracy.

4.2 Astronomy and Space Optics

OAP mirrors are indispensable in optical systems where light efficiency, weight, and resolution are critical.

- Ground-Based Telescopes: Infrared instruments like NASA’s NICMOS employ OAP optics to correct aberrations and enhance deep-space image resolution.

- Spaceborne Hyperspectral Imagers: SiC-based OAP mirrors reduce payload mass while maintaining λ/50 precision for hyperspectral image clarity.

4.3 Medical Imaging and Laser Therapy

Precision optics are essential in diagnostic and therapeutic instruments:

- Optical Coherence Tomography (OCT): Near-infrared OAP mirrors focus beams (800–1300 nm) for micron-scale imaging of retinal layers.

- Laser Surgery: Ensures uniform laser energy distribution (<5% deviation) for safe and precise ophthalmic and dermatological treatments.

4.4 Semiconductor and Microelectronics

At the forefront of nanofabrication, OAP mirrors play a pivotal role:

- Extreme Ultraviolet (EUV) Lithography: Molybdenum-silicide multilayer-coated OAP mirrors focus 13.5 nm light onto wafers for sub-7 nm processes.

- Wafer Inspection: Enables nanoscale defect detection (≥50 nm) via tightly focused laser scanning systems.

4.5 Quantum and High-Energy Physics

- Quantum Communication: Collimates single photons in QKD systems to reduce transmission loss.

- Synchrotron Radiation Detection: Collects fluorescence for accurate tracking of high-energy particles.

5. Future Outlook

As optical system performance advances toward nanometer precision and wider spectral integration, OAP mirrors remain at the heart of innovation. Avantier is focusing on three strategic directions:- Large-Aperture, High-Precision Integration: Scaling mirror sizes while maintaining λ/50 accuracy.

- Next-Generation Materials: Exploring diamond and aluminum nitride substrates for ultra-stable optics.

- AI-Assisted Manufacturing: Implementing predictive algorithms for real-time surface correction and efficiency optimization.

Conclusion

Off-axis parabolic mirrors represent a cornerstone technology for high-precision optical systems. Through rigorous material control, precision fabrication, and system-level integration, Avantier delivers OAP mirrors that meet the exacting demands of the world’s most advanced optical applications — where every nanometer counts.

Related Content