Key Takeaways

- Risk reduction in space optics is vital since components cannot be repaired once launched.

- Avantier ensures reliability through pre-qualification (testing materials, coatings, adhesives, and processes upfront) and designing for qualification (early collaboration, standards compliance, and performance margins).

- Supporting practices—thermal-vacuum and vibration testing, contamination control, and full documentation—further strengthen mission assurance.

- This integrated, qualification-driven approach minimizes delays, prevents failures, and provides customers with confidence that optics will perform flawlessly in the harsh conditions of space.

Why Risk Reduction is Mission-Critical

In space missions, failure is not an option. Optical components—mirrors, lenses, filters, and coatings—must perform flawlessly under extreme conditions: vacuum, radiation, vibration, and temperature. Unlike terrestrial optics, once launched, there is no chance for repair. This makes risk reduction in space optics projects absolutely critical. Precision optical component providers must ensure their solutions are not only high-performing in the lab but also fully qualified for the harsh realities of space. At Avantier, we specialize in two pillars that dramatically reduce risk for our customers:- Pre-Qualification of optical components and processes

- Designing for Qualification in collaboration with mission teams

Pre-Qualification of Optical Components

Pre-qualification means testing and proving materials, coatings, adhesives, and processes before they ever touch a customer’s project. This proactive approach prevents late-stage surprises that can derail schedules or compromise performance.Key Benefits of Pre-Qualification

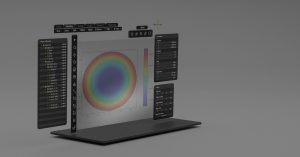

- Materials & coatings stability: Glass substrates, thin-film coatings, and bonding adhesives are tested under vacuum and thermal cycling. This ensures coatings don’t crack, adhesives don’t outgas, and optics retain their figure under stress.

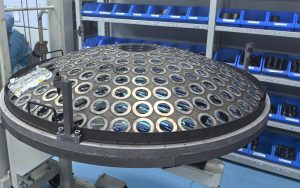

- Repeatable processes: Manufacturing equipment, coating chambers, and cleaning protocols are qualified with witness samples, guaranteeing repeatability.

- Flight heritage & credibility: Documented success in past missions shows agencies and prime contractors that components can be trusted.

Designing for Qualification: Partnering for Mission Success

While pre-qualification eliminates material and process risks, Designing for Qualification ensures that optics are conceived from the start to meet space requirements.What Designing for Qualification Involves

- Early design collaboration: We participate in customer design reviews to recommend manufacturable and testable designs. For instance, we advise on coating stacks that are already proven in space environments.

- Built-in standards compliance: Designs are aligned with MIL-PRF-13830 (U.S. military standard for optics) and ECSS standards (European Cooperation for Space Standardization). This ensures compliance from day one.

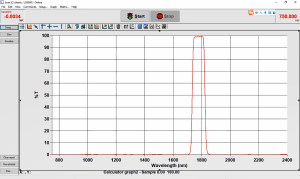

- Performance margins: Where possible, we qualify optics at higher performance than required. For example, if a filter must transmit >95% after radiation exposure, we design and test it at >97%. This margin provides insurance over mission life.

Supporting Practices That Strengthen Risk Reduction

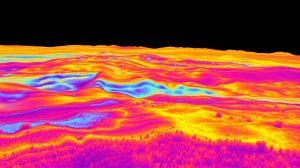

While our specialty lies in pre-qualification and design, we reinforce these pillars with supporting practices that complete the risk-reduction framework.Thermal-Vacuum and Vibration Testing

- TVAC testing proves optical stability under space-like thermal and vacuum conditions.

- Vibration and shock testing simulates launch loads, verifying mechanical mounts and coatings remain intact.

Contamination Control

Even microscopic residue can degrade optics in orbit. We manufacture in ISO-class cleanrooms, use strict handling protocols, and monitor coating runs with witness samples.Documentation & Standards Compliance

- MIL-PRF standards define acceptance criteria for scratch-dig, coating durability, and surface quality.

- ECSS standards provide harmonized testing and inspection frameworks for ESA missions.

- Traceability: Every component is documented from raw material lot to final inspection, ensuring complete pedigree and easy acceptance by agencies.

Case Examples from Space Optics Projects

- Coating Outgassing in TVAC: A mirror coating passed ambient testing but failed under thermal-vacuum cycling due to outgassing. Pre-qualification with alternate materials solved the issue and prevented launch delays.

- Documentation Gaps: A project faced delays when optics were rejected for incomplete ECSS documentation. Once full traceability was provided, acceptance was granted without further rework.

👉 These real-world lessons underline why qualification-driven processes save customers both time and cost.

Conclusion: Delivering Confidence in Precision Optics

Risk reduction in space optics projects is not about one test or one inspection—it’s about an integrated approach. By combining pre-qualification, designing for qualification, environmental testing, contamination control, and documentation discipline, Avantier delivers more than components. We deliver confidence that optics will work the first time, every time, in space.

At Avantier, this qualification-driven mindset defines how we work. Customers trust us because we don’t just provide optics—we provide proven, space-ready solutions that help ensure mission success.

FAQ: Reducing Risk in Space Optics

Q1. What is pre-qualification in space optics?

Pre-qualification is the process of testing materials, coatings, adhesives, and processes under simulated space conditions before they are used in customer projects.

Q2. How does designing for qualification reduce risk?

It ensures that optical designs are manufacturable, testable, and compliant with standards (MIL-PRF, ECSS) from the start, preventing late-stage failures or redesigns.

Q3. Why is contamination control important for optics in space?

Even microscopic contamination can scatter light, reduce transmission, and degrade coatings in orbit. Strict cleanroom practices ensure optics remain pristine.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!