Key Takeaways:

- Optical processing transforms materials such as glass and crystals into precision components like lenses and mirrors, which are essential across industries including semiconductors, electronics, and biomedical devices.

- Key techniques include laser processing, ultra-precision polishing, optical coating, and computer-controlled surfacing.

- The shift from manual to automated methods has enabled nanometer-level accuracy, driven by the increasing demand for high-precision optics. These processes ensure dimensional accuracy and surface quality, meeting the growing need for reliable, efficient, and advanced optical components.

Optical processing, a crucial aspect of precision manufacturing, transforms materials such as glass, crystals, and plastics into optical components like lenses, prisms, and mirrors. Techniques like laser processing, ultra-precision polishing, optical coating, and computer-controlled surfacing drive this industry, supporting sectors including semiconductors, consumer electronics, and biomedical devices.

The Precision Path of Optical Manufacturing

Optical processing begins with raw materials and culminates in finely crafted optical components. Processes such as cutting, grinding, polishing, and coating ensure the highest standards of dimensional and surface quality. These components are essential for devices such as optical instruments, camera lenses, fiber optics, and laser systems. By combining traditional methods with modern automation, optical processing guarantees precise control over light, enabling accurate imaging and transmission.

Progress in Optical Processing Techniques

Over time, optical processing has evolved significantly, transitioning from manual labor to automated precision techniques. Early optical components were handmade, a labor-intensive process with limited precision. The introduction of mechanical methods in the early 20th century improved efficiency, while CNC machines and laser technologies in the mid-20th century enabled micron and nanometer-level accuracy, revolutionizing optical component production. This evolution has been driven by the growing demand for precision products, particularly in industries like semiconductors and electronics.

Core Technologies in Optical Manufacturing

- Optical Coating: Applying thin layers of material to optical components enhances properties like reflection, transmission, and polarization. For instance, anti-reflective coatings reduce glare in cameras and eyeglasses, improving clarity.

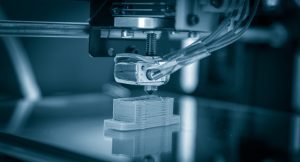

- Laser Processing: This technique uses high-energy laser beams for precise cutting, welding, marking, and engraving on materials like metals and glass. Its non-contact nature makes it ideal for fragile or high-melting-point materials, making it essential in electronics, automotive, and aerospace applications.

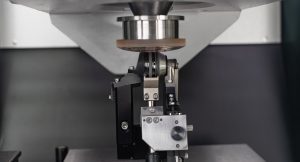

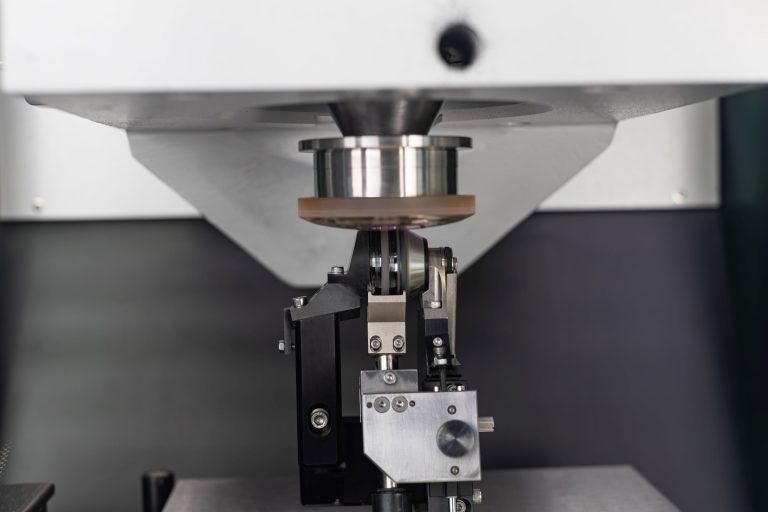

- Computer-Controlled Optical Surfacing (CCOS): Combining CAD, CAM, and precision machining, CCOS enables the production of complex optical elements like aspheric lenses and freeform mirrors with exceptional surface quality.

- Ultra-Precision Polishing (UPP): Methods such as magnetic rheological finishing are critical for producing smooth, precise surfaces, particularly on large or aspherical optical elements used in fields like astronomy.

Applications Across Key Industries

- Biomedical Devices: Optical processing enables the production of high-precision imaging tools like microscopes and diagnostic equipment.

- Consumer Electronics: High-quality optics are critical in smartphones and AR/VR systems, enhancing both image quality and user experience.

- Semiconductor Production: Optical processing is vital in photolithography and inspection and essential for manufacturing nanometer-scale circuits on silicon wafers.

Avantier’s Advanced Optical Processing

The optical processing industry is advancing toward greater precision and accommodating a broader range of component sizes, from large mirrors to micron-scale structures. There is a growing emphasis on integrating shape accuracy with optical performance, particularly for high-end products like aspheric lenses and diffractive elements. Additionally, the increasing use of integrated processing and real-time inspection technologies is helping to ensure that products meet strict quality standards throughout production.

Avantier’s processes address the rising demands for precision, reliability, and efficiency, supporting industries like semiconductors and consumer electronics. We stay ahead of industry trends by incorporating real-time inspection technologies to maintain the highest quality standards. Contact us today to learn how Avantier can meet your optical processing needs with cutting-edge precision and quality.

GREAT ARTICLE!

Share this article to gain insights from your connections!