Key Takeaways:

- Infrared lens design with aspherical lenses enhances wide field of view and optical systems by reducing the need for multiple spherical lenses.

- Aspherical lenses in infrared systems reduce complexity, volume, and weight, while improving overall transmittance.

- High-cost materials like germanium and zinc sulfide benefit from aspherical designs by lowering manufacturing costs.

- Advanced technologies like single-point diamond turning achieve high precision and surface quality in aspherical lens production.

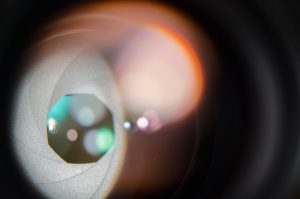

Advantages of Aspherical Lenses in Infrared Lens Design

Aspherical lenses can not only be used as a separate optical component, but can also replace spherical lenses in optical systems, providing more optimized freedom.This incresae of optimized freedom is conducive to eliminating various types of aberrations in the system, making it possible to design a lens with fewer lenses but better quality. In particular, it has unique advantages in the design of large relative aperture, wide field of view and zoom lens.

For infrared lenses, the use of aspherics is more common. Unlike ordinary lenses, infrared lenses use materials that need to transmit light in the infrared wavelength, such as germanium, zinc sulfide, zinc selenide, and so on. The price of such materials is much higher than that of ordinary glass, which leads to an increase in manufacturing costs if all optical components are designed with ordinary spherical lenses. The use of aspherical design in infrared lenses can reduce the complexity of the system and reduce the volume and weight of the system. Although the processing of aspherical lenses is more complex, reducing the use of infrared materials can often reduce the overall cost. At the same time, due to the simplification of the system, the influence of tolerances brought by optical components and structural components can be reduced, and the stability of the process can be improved. In addition, the reduction in the number of lenses also helps to reduce the loss of light transmission and improve the overall transmittance of the system.

Wide field of view (FOV) Infrared Lens Specificiations

Material | Chalcogenide glass |

Shape | Convexo-concave lens, double-sided aspherical surface |

Diameter | 36mm |

Thickness | 3mm |

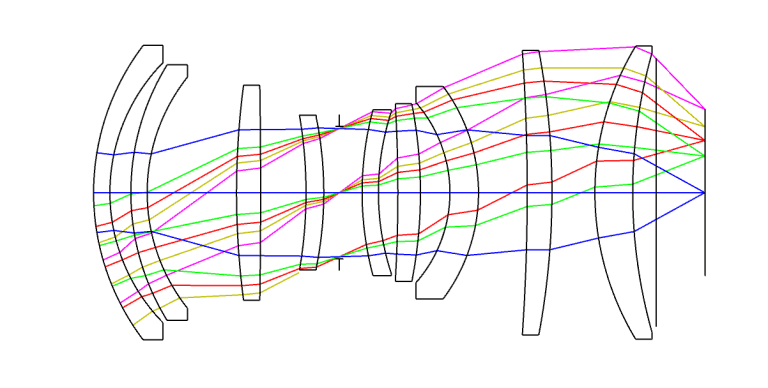

Project Overview

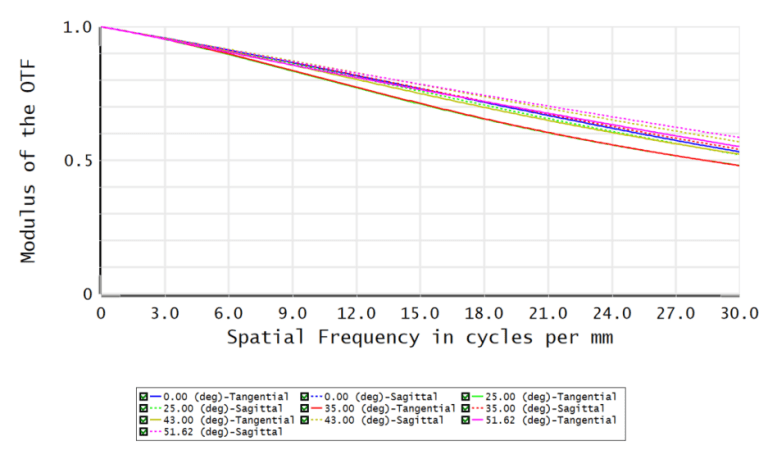

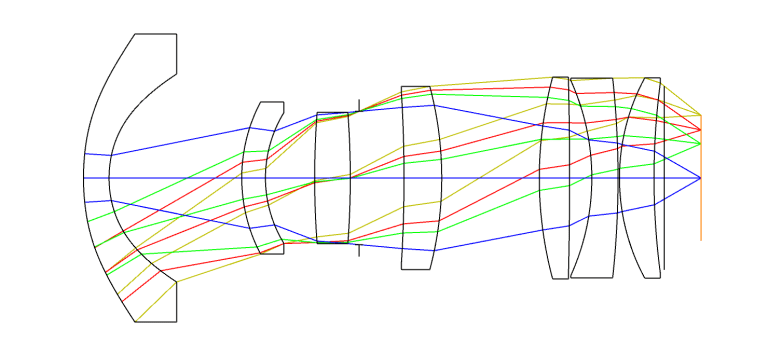

The following is a wide field-of-view long wavelength infrared lens design, optical elements are all spherical lenses, considering the non-thermal treatment, the material is made of chalcogenide glass and germanium. The lens structure is complex, and the field of view angle is 103°.

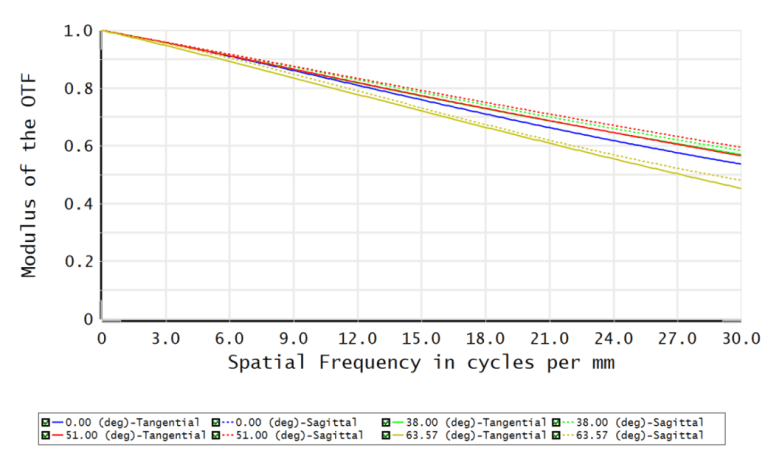

Changing the first lens to an aspherical design significantly reduces the complexity of the lens design and further expands the lens field of view to 127°.

Material and Manufacture

The main composition of chionoid glass is germanium / arsenic / seleno / antimony (ge-as-se-sb) and other elements, which has high transmittance and low refraction-temperature coefficient in the infrared band, and is a relatively cheap infrared material. Low-cost and high-efficiency processing of chalcogenide glass is also an important research direction in the field of infrared lens processing. Suppose the traditional cold processing method is used to process chalcogenide glass. In that case, there are more molds, processes and equipment involved. Also, the quality of this processing method is unstable, and the cost of labor and auxiliary materials is high.

For small batch production, this kind of lens is generally processed by single point diamond turning technology, as the chalcogenide glass material is soft and the thermal expansion coefficient is large. As a high efficiency and high precision optical surface processing method, single point diamond turning technology can directly produce optical components with nanometer surface roughness and sub-micron shape accuracy, and has become the best solution to realize optical surface processing for a variety of optical applications. Ultra-precision single point diamond turning technology improves the precision, repeatability and finish of the machined surface, and can be formed once and reduce the processing time. Plus, its surface roughness is mere nanometers.

Conclusion

In conclusion, the adoption of aspherical lenses, especially in infrared lens design, offers substantial benefits that outweigh the challenges posed by their complex processing. By incorporating aspherics, optical systems can achieve improved aberration correction, reduced component count, lower weight and volume, and enhanced overall transmittance.

These advantages are particularly significant in the case of infrared lenses, where materials like chalcogenide glass and germanium are utilized, which necessitate cost-effective design solutions. Despite the intricacies involved in processing aspherical lenses, advancements in technologies like single-point diamond turning have made it feasible to achieve nanometer-level precision and surface quality efficiently.

Consequently, the transition to aspherical designs not only optimizes optical performance but also contributes to cost savings, process stability, and streamlined manufacturing in infrared lens applications, reinforcing the pivotal role of aspherics in modern optical engineering.

GREAT ARTICLE!

Share this article to gain insights from your connections!