Key Takeaways

- A global leader in agricultural genetics sought durable, cost-effective UV microscope objectives.

- Challenges included optical design complexity, wavefront control, and fabrication precision.

- By optimizing coatings, manufacturing, and materials, we extended the lens lifespan from 3 to 18 months, reducing replacement costs and downtime.

- Avantier’s customized optical coatings improved both performance and durability, ensuring reliable genetic analysis. This collaboration set a new standard for high-performance, cost-efficient UV microscope objectives in livestock genetics and reproduction.

Project Background: UV Microscope Objectives for Genetic Analysis

A global leader in agricultural genetics and reproduction services approached us to address problems they were facing related to the cost and durability of microscope objective lenses. These lenses play a pivotal role in analyzing genetic data, directly impacting the company’s efficiency and operational costs. By partnering with us, they hoped to enhance the performance and longevity of their UV microscope objectives.

Challenges in Designing and Manufacturing UV Microscope Objectives

- Optical Design Complexity Designing UV microscope objectives involves navigating the unique properties of UV light, such as shorter wavelengths, higher photon energy, and lower transmittance. Advanced optical design techniques needed to be employed to deliver optimal imaging across the entire field of view. One aspect of this was the development of apochromatic equation systems to correct chromatic and spherical aberrations.

- Material Selection and Manufacturing Processes UV-grade fused silica, prized for its high damage threshold and minimal scattering properties, was selected as the primary substrate. A specialized process was implemented during manufacturing to ensure the highest levels of cleanliness and mitigate potential contamination that could compromise imaging quality.

- Wavefront Aberration Control Maintaining wavefront aberration below λ/5 across the full wavelength range was crucial for achieving high-resolution, low-distortion imaging. This required meticulous optimization in both the design and manufacturing stages.

- Precision Fabrication and Testing The high photon energy associated with UV light demands exceptional surface quality and precision in optical components. Advanced fabrication techniques, coupled with state-of-the-art metrology technologies, were employed to meet these exacting requirements.

- Cost and Efficiency Challenges High production costs traditionally limit the widespread adoption of UV microscope objectives. Addressing this, we focused on reducing manufacturing expenses while maintaining stringent quality standards and optimizing production efficiency.

Solutions and Outcomes

- Customized Optical Coatings To meet the company’s specific needs, a customized optical coating solution was developed in collaboration with Avantier. These coatings enhanced the durability and performance of the microscope objectives, enabling them to withstand the demanding conditions under which they were used.

- Significant Longevity Improvements Through the implementation of advanced materials, coatings, and precision manufacturing processes, the operational lifespan of the UV microscope objectives was extended from 3 months to 18 months—a sixfold increase in durability.

- Cost and Time Savings The extended longevity of the lenses drastically reduced the frequency of replacements, leading to substantial cost savings and minimized instrument downtime. This improvement streamlined the operations of the genetic analysis company, enabling them to allocate resources more effectively.

Use Case 2 – Technical Challenges in Deep Ultraviolet Imaging

Deep Ultraviolet Wavelength Constraints

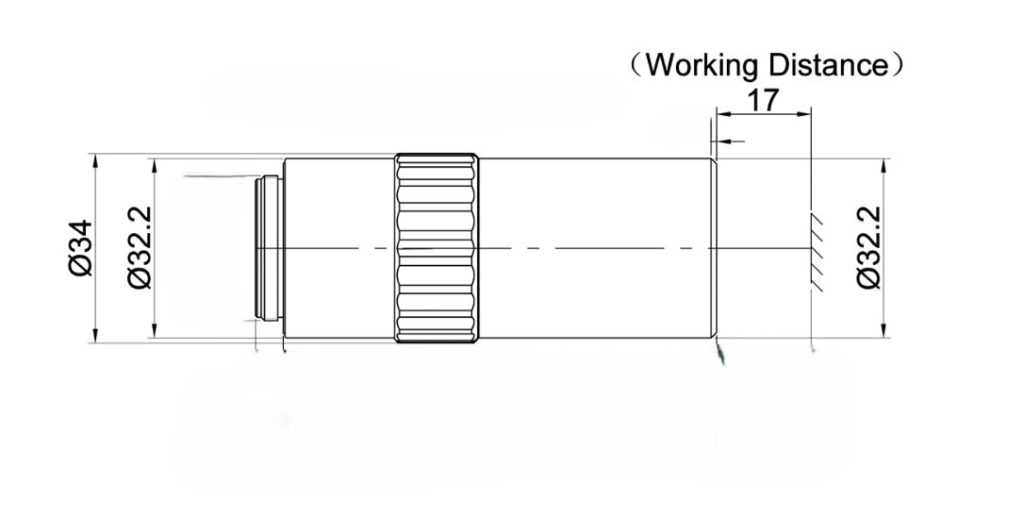

Operating at deep ultraviolet wavelengths presents significant optical challenges due to shorter wavelengths, increased sensitivity to surface errors, and reduced material transmittance. The system was required to operate at 265 nm (±5 nm) and 365 nm (±15 nm) while maintaining high image fidelity and stability.

High Numerical Aperture Objective Design

To reach the desired resolution, the microscope objective needed a numerical aperture of ≥ 0.85. Designing a high-NA objective for DUV operation required careful correction of higher-order aberrations and strict control of wavefront quality, as even minor deviations are amplified at shorter wavelengths.

Wavefront Error and Resolution Control

Achieving diffraction-limited performance at DUV wavelengths demanded exceptional wavefront control. The objective was optimized to maintain a wavefront error RMS ≤ 0.03λ, ensuring minimal aberration contribution from the optical system and enabling true high-resolution imaging.

System-Level Integration

Rather than functioning as a standalone consumer microscope, the system was configured as a custom objective-based optical system, where overall performance was defined primarily by the DUV objective. A UV-compatible tube lens was precisely matched to the objective to preserve resolution, contrast, and distortion control throughout the imaging path.

Optical Design and System Specifications

- Imaging Magnification: 100×

- Objective Numerical Aperture: ≥ 0.85

- Operating Wavelengths:

- 265 nm ± 5 nm

- 365 nm ± 15 nm

- 265 nm ± 5 nm

- Objective Performance:

- Wavefront Error RMS ≤ 0.03λ

- Wavefront Error RMS ≤ 0.03λ

- System Performance:

- Measured imaging resolution better than 100 nm

- Measured imaging resolution better than 100 nm

The system architecture follows an objective-driven design philosophy, where the microscope’s performance is fundamentally determined by the optical quality of the DUV objective itself.

Results and Outcomes

The completed DUV microscope optical system achieved a measured imaging resolution of 100 nm, meeting the demanding requirements of semiconductor inspection applications. The high-NA objective delivered excellent contrast, minimal distortion, and stable performance across the specified ultraviolet wavelength bands.

By focusing on objective-level performance and precise system integration, the solution provided a robust, application-specific alternative to conventional microscope platforms, offering both higher resolution and greater optical customization.

Conclusion: Custom DUV Optical Systems Enabled by High-Performance Objectives

This case study demonstrates how a custom deep ultraviolet microscope optical system, built around a high-NA DUV objective lens, can deliver exceptional imaging performance for semiconductor inspection. Rather than relying on standardized microscope architectures, this approach emphasizes objective-centric design, precise wavefront control, and wavelength-specific optimization.

The project highlights Avantier’s capability to develop specialized UV and DUV microscope objectives and optical systems tailored to demanding industrial and research applications.

Enhancing UV Microscope Objectives

By addressing the complexities of UV light, selecting the best materials, and employing cutting-edge manufacturing techniques, we successfully delivered a robust solution that exceeded our client’s expectations. The collaboration not only resolved their immediate challenges but also set a new benchmark for cost-efficient, high-performance UV microscope objectives in the field of genetics and reproduction.

Please contact us if you’d like to request a quote on your next project.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!