Key Takeaways – Optimized Lightweighting Design for a NIR Reflective Mirror

- The original design’s thin ribs and deep pockets achieved greater mass reduction (0.61× the optimized design) but introduced higher deformation risk and lower manufacturability.

- The optimized geometry by Avantier provides improved stiffness, reduced thermal distortion, and more reliable machining.

- Overall, the optimized design offers a better engineering balance than the more aggressively lightweighted original.

Project Overview

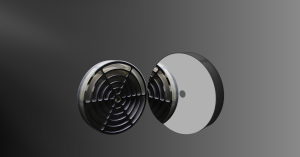

The project required designing a lightweight near-infrared (NIR) reflective mirror with a machined backside pocket structure. The goal was to reduce mass while preserving structural rigidity, thermal stability, and manufacturability.

Design Comparison

Two design concepts were evaluated via structural and thermal simulation:

Parameter | Customer’s Original Design | Optimized Design |

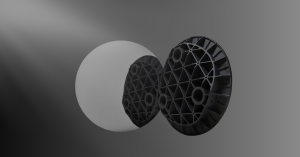

Remaining Rib Thickness | Very thin rib structure | Thicker, more robust rib structure |

Pocket Depth | Deep pocket geometry | Moderately reduced pocket depth |

Relative Weight | 0.61× of optimized design | Baseline |

The customer’s design achieves a more aggressive mass reduction due to thinner ribs and deeper pockets. However, simulation results show that weight alone is not a sufficient metric for determining design quality.

Engineering Assessment

1. Structural Rigidity and Mechanical Response

- The 3 mm ribs in the original concept exhibit significantly higher deflection and stress concentration under typical mounting and operational loads.

- The optimized 6 mm rib structure distributes stress more evenly, reducing risk of fracture and improving modal stiffness—critical for optical stability.

2. Thermal Stability

- Deep pockets (38 mm) introduce larger temperature gradients and increase sensitivity to thermal bowing.

- The reduced pocket depth (31.5 mm) in the optimized design lowers thermal deformation, improving optical surface stability in both high- and low-temperature cycles.

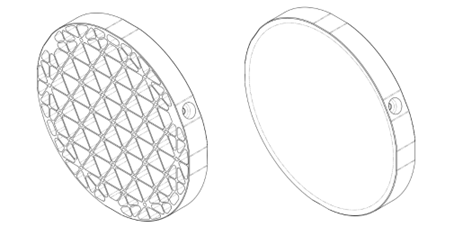

3. Manufacturability

- Extremely thin ribs raise machining difficulty, increase scrap rate, and reduce repeatability.

- The optimized rib geometry improves tool accessibility, reduces vibration during machining, and provides consistent dimensional accuracy.

4. Operational Reliability

- Combined structural and thermal analyses indicate the original design approaches critical limits in fatigue and deformation.

The optimized configuration provides a more robust safety margin, enabling long-term reliability without significant mass penalty.

Conclusion

Although the customer’s original design achieves greater weight reduction (0.61× of the optimized design), engineering evaluation shows that lightweighting must balance multiple factors—not just mass. Considering manufacturability, structural integrity, thermal behavior, and operational reliability, the optimized design delivers a more stable and production-ready solution while still achieving meaningful weight reduction.

GREAT ARTICLE!

Share this article to gain insights from your connections!