Key Takeaways

- Enhanced Thermal Stability with CFRP: Replacing the optical tube with carbon fiber composite significantly reduced weight while ensuring structural integrity under extreme temperature swings.

- Precision Engineering: A redesigned secondary mirror mount with locating pins and adhesive injection holes ensured precise, long-term alignment.

- Optimized Performance: These telescope design optimizations delivered a high-performance system meeting λ/4 wavefront error and >90% transmittance specifications.

Project Background

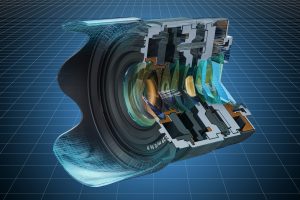

A high-performance optical telescope system was under development for aerospace imaging applications, requiring not only precision optical alignment but also robust manufacturability. Initial telescope designs raised concerns related to weight, alignment stability, and assembly complexity, especially in demanding environments. A series of design optimizations were undertaken to address these challenges while preserving optical performance.

Objectives

- Reduce system weight without compromising structural stability

- Improve ease of assembly and alignment

- Ensure long-term positional stability of optical elements

- Maintain high optical performance:

- Surface Quality: 60-40 Scratch-Dig

- Transmitted Wavefront Error: λ/4

- Transmittance: T(peak) S&P > 95%, Tavg > 90%

- Surface Quality: 60-40 Scratch-Dig

Optimization 1: Carbon Fiber Optical Tube Replacement

Before:

The optical tube was originally constructed using aluminum alloy, which provided strength but added unnecessary weight and was prone to thermal expansion.

Solution:

The optical tube material was replaced with carbon fiber composite, which offers:

- Lightweight properties (reducing total mass for space payload requirements)

- High modulus and thermal stability (critical for preserving alignment under varying temperatures)

- Ease of manufacturing using filament winding and layup techniques

- Proven aerospace reliability

Impact:

The carbon fiber tube significantly reduced system weight and thermal drift, improving both launch survivability and in-orbit optical stability.

Optimization 2: Secondary Mirror Mounting Redesign

Before:

The secondary mirror mounting lacked defined reference points, resulting in difficulties during assembly and potential long-term misalignment under vibration or thermal cycling.

Solution:

The design was enhanced by incorporating:

- Precision locating pins for accurate mirror placement

- Adhesive injection holes to secure bonding without introducing stress or voids

Impact:

The new mounting configuration allowed for repeatable positioning with enhanced structural integrity, maintaining optical alignment over time and across varying operating conditions.

Optimization 3: Primary Mirror Alignment Enhancement

Before:

The interface between the primary mirror and the tube relied solely on fixed contact points, limiting adjustability during assembly.

Solution:

- Adjustment shims were added to allow micro-adjustments during alignment

- Positioning pins were included to lock in alignment post-calibration

Impact:

This change enabled precise axial and angular alignment between the primary and secondary mirrors during assembly, ensuring optimal system performance while minimizing rework or field adjustment.

Conclusion

Through targeted mechanical redesign—specifically in material selection, optical component mounting, and alignment methodology—the team achieved a more robust, lightweight, and manufacturable telescope system. The result met all optical specifications and exceeded structural and thermal performance expectations for aerospace deployment.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!