Key Takeaways

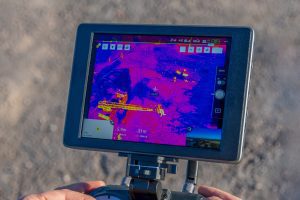

- A client in a specialized industry sought a germanium lens to enhance situational awareness in low-light and low-visibility environments.

- The project presented challenges, including meeting stricter surface quality specifications and managing distortions from the coating process.

- Through advanced manufacturing and refined polishing techniques, we successfully delivered a lens that met the customer’s 40-20 surface quality requirement.

- The outcome was a high-performing germanium lens tailored to the customer’s specific needs, improving situational awareness in challenging environments.

Project Background: Germanium Lens for Low-Visibility Applications

A client approached us to develop a custom germanium lens designed for use in low-visibility environments. The lens was intended to enhance situational awareness in conditions such as fog, smoke, or low-light, where optical clarity is essential for effective performance. Our task was to manufacture the lens to meet specific surface quality and optical performance requirements.

Challenges in Designing and Manufacturing the Germanium Lens

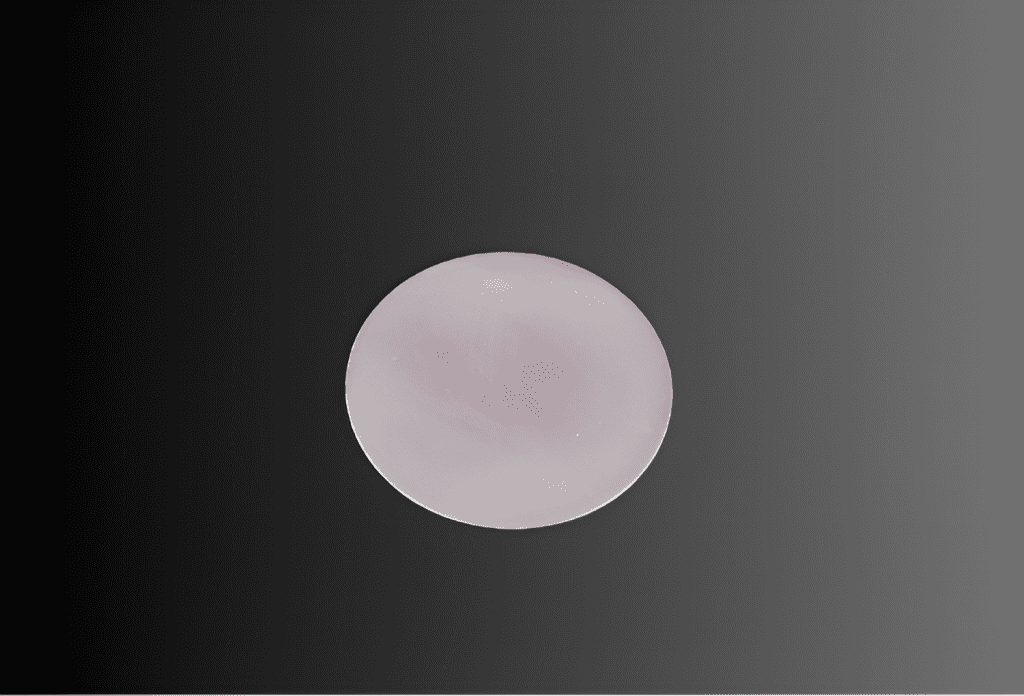

- Surface Quality Specification Initially, we proposed a 60-40 surface quality standard, which is typical for this type of lens. However, the customer insisted on achieving a 40-20 surface quality, a more stringent requirement. This change presented challenges due to the inherent characteristics of germanium material, which is difficult to polish to tighter tolerances.

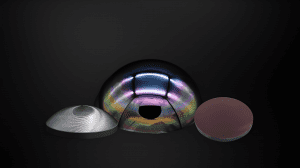

- Coating Distortions The lens was to be coated with DLC (Diamond-Like Carbon), which can cause distortions in the surface accuracy. The DLC coating process can slightly alter the geometry of the lens, further complicating the ability to meet tight surface quality specifications.

- Material Limitations Germanium, a polycrystalline material, tends to have more surface imperfections than single-crystal materials. These imperfections are challenging to polish to higher surface quality standards, especially at the 40-20 level required by the customer.

- Performance Requirements The lens needed to meet specific optical transmission characteristics. Achieving these performance metrics while maintaining the desired surface quality added additional complexity to the design and manufacturing process.

Solutions and Outcomes

- Refined Polishing Techniques To meet the customer’s 40-20 surface quality requirement, we implemented advanced polishing techniques that involved more meticulous control of the polishing process. This ensured the lens was polished to the tight tolerances needed.

- Pre-Coating Surface Inspection We introduced additional inspection steps before applying the DLC coating to ensure the lens met the required surface quality. This pre-coating inspection helped us identify any imperfections early, preventing potential distortions during the coating process.

- Optimized Coating Process We adjusted our DLC coating process to minimize any potential distortions caused by the coating while maintaining the lens’s durability and optical performance. This ensured that the final product met both the surface quality and performance requirements.

- Extensive Testing After manufacturing, the lens underwent extensive performance testing to ensure it met the necessary optical specifications. This included testing the lens’s ability to function in low-visibility conditions, as per the customer’s intended application.

Outcome

We successfully delivered a custom germanium lens that met the customer’s updated 40-20 surface quality specification. The lens performed optimally in low-visibility environments, providing enhanced situational awareness as required. This project highlighted our ability to adapt to challenging material and customer demands, ensuring high-quality and high-performance optics.

By addressing the challenges in material polishing, coating distortions, and optical performance, we were able to provide a solution that not only met but exceeded the customer’s expectations, demonstrating our capability to manufacture highly specialized lenses for demanding applications.

GREAT ARTICLE!

Share this article to gain insights from your connections!