Key Takeaways

- Custom microlens array design enables tailored optical solutions for diverse applications like imaging and photonics.

- Precision engineering, material selection, and overcoming fabrication challenges are crucial for meeting specific performance requirements, as highlighted in our case studies.

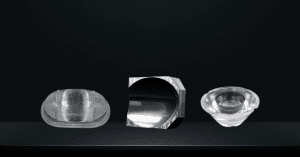

Microlens arrays are composed of multiple lens cells arranged on a glass, polymer, or metal substrate in 1D or 2D patterns. They are designed to manipulate light precisely, serving applications in lighting, imaging, and photonics.

By strategically arranging lenses, these arrays enhance beam control, improve system efficiency, and support advanced optical functions. Their substrate and configuration can be customized to meet specific application needs, making lens arrays a versatile tool in modern optics.

Case Study 1: Custom Microlens Array for Concept Demonstration

Project background:

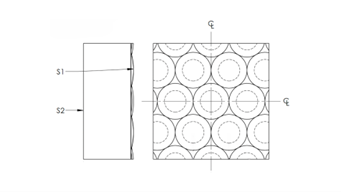

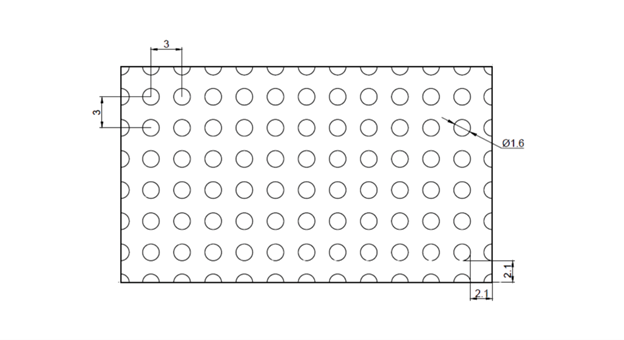

A leading research laboratory required Avantier’s assistance in creating a custom microlens array (MLA) for a prototype in the advanced optics field. The MLA specifications included plano-convex, spherical, refractive lenses arranged in a hexagonal pattern with a 310 µm pitch, a near full fill factor, and a 541 µm radius of curvature. The footprint was to measure 30 mm × 10 mm, fabricated on a 100 µm thick N-BK7 substrate or equivalent. An aperture coating with a clear 250 µm diameter opening under each lens was also requested.

Requirement Challenges and Solutions:

High Precision Requirements: The design required sub-micron fabrication tolerances across a relatively large area.

Solution: The Avantier engineering team employed single-point diamond turning (SPDT) with ultra-precise CNC-controlled diamond tools. This enabled the accurate fabrication of spherical features and ensured consistent curvature across the array, meeting the tight tolerance and fill fraction requirements.

Case Study 2: Optical Design Optimization for Hyperspectral Sensors

Project background:

A company in the hyperspectral sensor industry sought a custom microlens array (MLA) to enhance optical performance beyond what standard arrays could achieve. Their design included specific requirements for refractive index and spectral response.

Challenges and Solutions:

Material Compatibility: The initially selected substrate material did not meet the required optical properties for optimal system performance.

Solution: Avantier proposed an alternative material with a refractive index of 1.516728 at 589.29 nm, which provided a closer match while maintaining optical clarity and compatibility with fabrication processes. This ensured the array met the design specifications. Although the availability of suitable materials remained a challenge, we assisted the customer with sourcing strategies and production planning to minimize delays and maintain project momentum.

Custom Microlens Arrays

At Avantier, we specialize in creating custom optics that meet the precise needs of your application, and microlens arrays are one of our areas of expertise. Contact us today for more information or to schedule an initial consultation.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!