Infrared Lens Design Case Study: Applying Design for Manufacturing (DFM) to Reduce Costs by 60%

- Avantier applied Design for Manufacturing (DFM) to redesign a 50 mm f/1 infrared lens, cutting production costs by 60%.

- The new design replaced toxic gallium arsenide with safer materials and swapped costly aspheric lenses for optimized spherical ones.

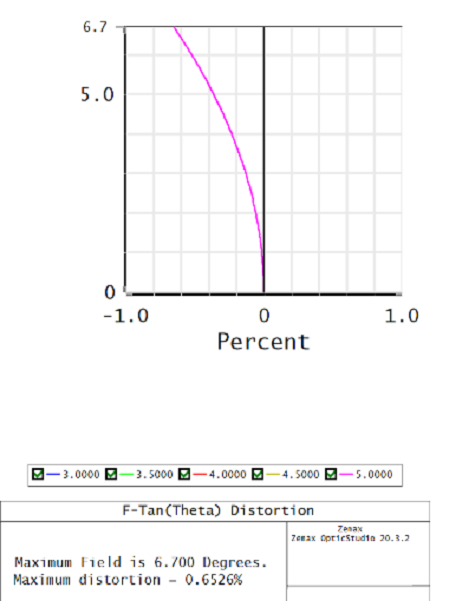

- The result maintained high imaging quality (MTF 0.7, < 0.7% distortion) while simplifying manufacturing and improving safety.

- This case highlights how DFM enables cost-efficient, compliant, and scalable optical designs without sacrificing performance.

Introduction: Balancing Performance and Manufacturability

Designing advanced optical components often means facing trade-offs between performance, cost, and manufacturability. At Avantier, we apply Design for Manufacturing (DFM) principles to help clients overcome these challenges.

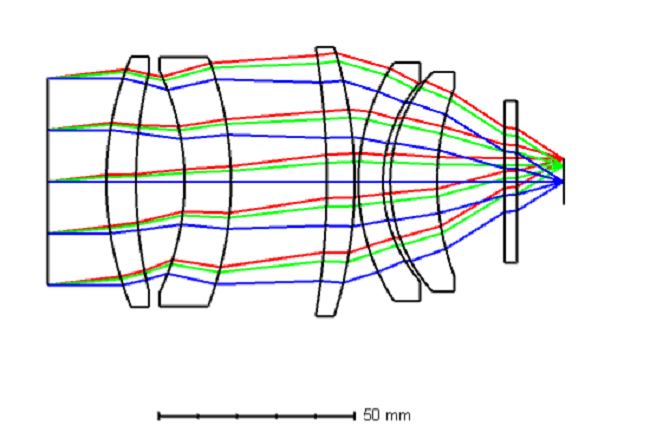

In this case study, we redesigned a 50 mm f/1 infrared lens for a scientific equipment supplier. The original design delivered excellent imaging performance but was prohibitively expensive and complicated to manufacture. By applying DFM, we reduced production costs by 60%, eliminated toxic materials, and maintained the lens’s high performance standards.

The Challenge: A High-Performance Lens with Manufacturing Limitations

A scientific equipment supplier approached us for help with the design of a critical component in their infrared spectral imaging system. Their 50 mm f/1 infrared lens was essential for monitoring gases such as carbon monoxide, combustion products, and unburned hydrocarbons using multispectral infrared imaging.

While the lens performed well in terms of modulation transfer function (MTF) and distortion, two major issues made manufacturing inefficient and costly:

- Expensive aspheric lens elements increased production complexity.

- Gallium Arsenide (GaAs) was included to correct chromatic aberration and improve MTF, but it is a toxic material that raised compliance, safety, and cost concerns.

The client needed a solution that balanced scientific imaging performance with practical manufacturing requirements.

Our Approach: Redesigning with DFM Principles

Avantier’s optical engineering team applied Design for Manufacturing strategies to simplify production without compromising performance. Key steps included:

- Eliminating aspheric elements by re-engineering the optical configuration.

- Replacing GaAs with safer alternatives to reduce toxicity risks.

- Optimizing performance vs. cost using spherical lenses and standard materials.

The final design used five spherical lens elements and one filter, delivering comparable optical performance while being significantly easier and safer to produce.

The Results: A Safer, More Cost-Effective Infrared Lens

Our redesigned 50 mm f/1 infrared lens achieved:

- 60% cost reduction compared to the original design.

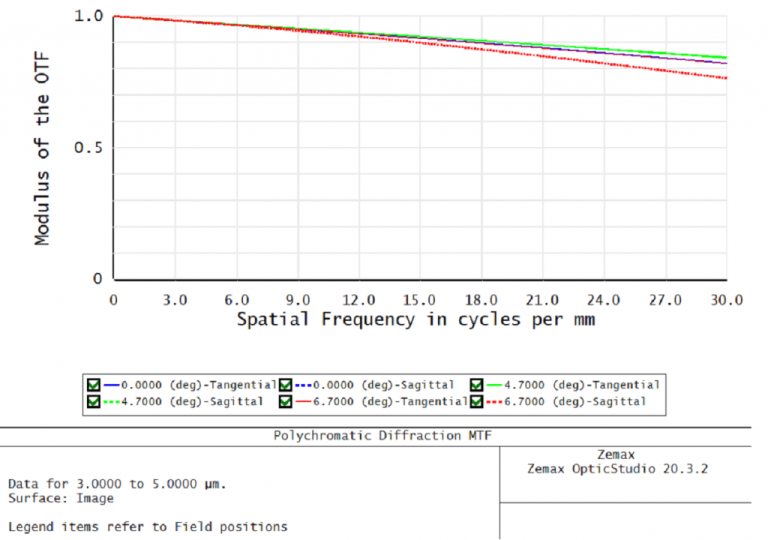

- MTF of 0.7 across the 3–5 µm wavelength range, well within client requirements.

- Lens distortion of just 0.6526% at a maximum field of 6.7°.

- Complete removal of hazardous GaAs, ensuring safer and more scalable manufacturing.

This balance of performance, safety, and manufacturability gave the client a commercially viable lens design that supports continuous, real-time spectral imaging without the burden of high manufacturing costs.

Why DFM Matters in Optical Design

By integrating DFM into optical engineering, manufacturers and researchers benefit from:

- Reduced production costs through smarter material and component choices.

- Simplified manufacturing processes that avoid overly complex or toxic elements.

- Improved compliance and safety, essential for scientific and industrial use.

- Scalable production, ensuring designs can move from prototype to mass production efficiently.

At Avantier, we specialize in applying Design for Manufacturing (DFM) to optical and infrared lens design, helping clients cut costs while maintaining high performance.

👉 If you’re struggling with high-cost or difficult-to-manufacture optical components, our team can help. Contact us today to schedule a consultation and learn how DFM can make your optical systems safer, more efficient, and cost-effective.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!