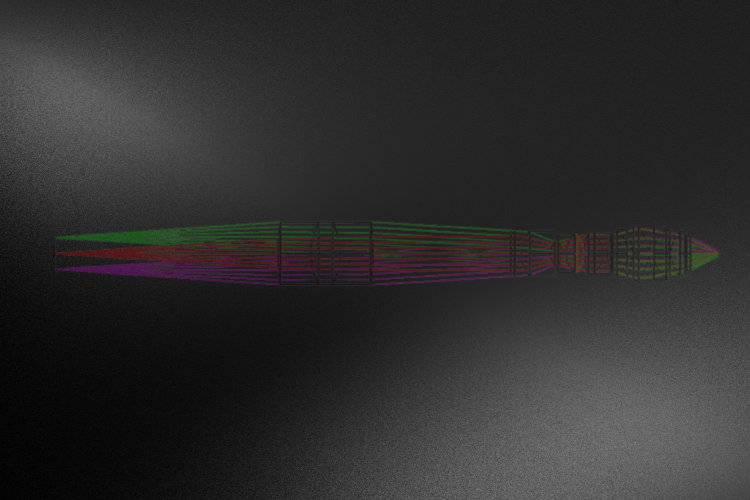

Key Takeaways Asymmetric Precision: Standardizing cylindrical lens metrology is crucial for mitigating “smile” distortion and beam steering caused by optical-mechanical axis misalignment. Advanced Centering Protocols: Moving beyond mechanical inspection to laser phase-shift interferometry enables the detection of axial tilt and eccentricity with sub-arc-second resolution. Imaging Quality Assurance: Utilizing Transmitted Wavefront Error (TWE) analysis and focal […]