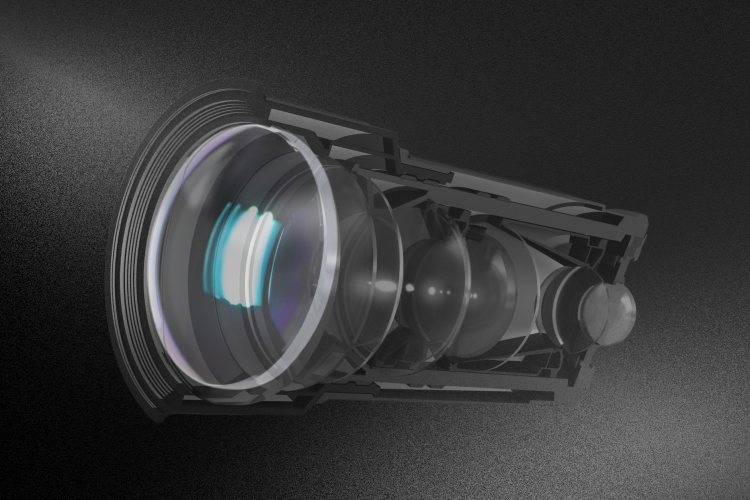

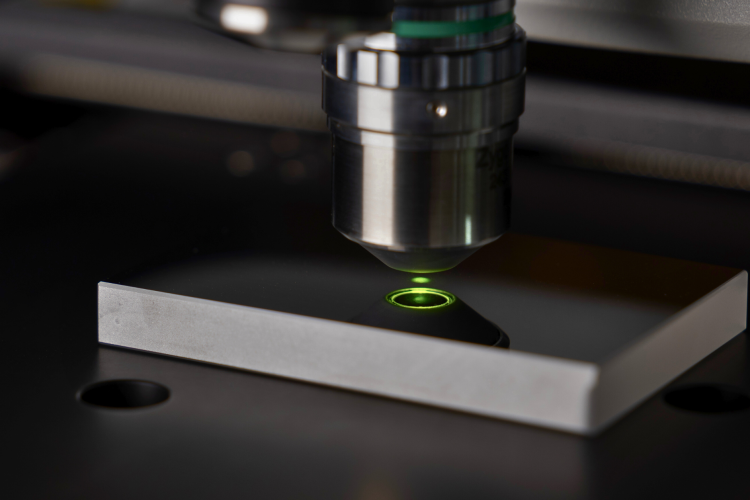

Key Takeaways: We offer precision lens transmittance testing using light intensity ratio and integrating sphere methods. These techniques ensure high optical performance, verifying brightness, color accuracy, and system efficiency across application-specific wavelengths. Our lab-built setups deliver reliable results for coated, curved, or multi-element lenses. While we don’t use high-speed laser transmittance meters, our capabilities meet […]