What Lenses Are Best for Space Applications Requiring High Image Quality and Light Collection?

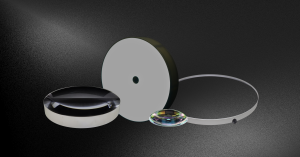

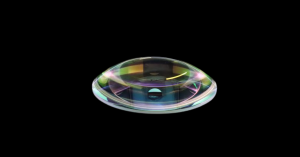

Answer: The optimal choice for space-based imaging and sensing systems is the large-aperture aspherical lens. These precision-engineered optics provide unmatched aberration correction, light-gathering ability, and durability under extreme conditions such as wide temperature fluctuations, radiation exposure, and launch vibrations.

Why Space Optics Require Specialized Lenses?

- Improved Image Quality Through Aberration Control

Traditional spherical lenses introduce spherical and coma aberrations, degrading resolution at the field edges. Aspherical lenses eliminate these issues, providing uniform clarity across the full aperture. A single asphere can replace multiple spherical elements, minimizing alignment complexity and significantly reducing payload weight—an essential benefit in spacecraft design. - Maximum Light Collection and Precise Wavefront Control

Large apertures up to 1,000 mm in diameter deliver high photon throughput, enabling high-resolution imaging and remote sensing even in low-light deep-space conditions. Surface accuracy at RMS ≤ 1/200λ (λ = 632.8 nm) allows sub-nanometer wavefront control, critical for both imaging and high-energy laser applications. - Durability in Harsh Environments

Manufactured from Zerodur, fused silica, or H-K9L, these lenses are engineered to maintain dimensional stability under severe thermal cycles, mechanical stress, and radiation exposure. Their performance remains consistent in the vacuum of space, making them a reliable component for long-duration missions.

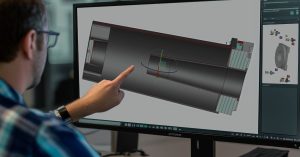

How Space-Grade Lenses Are Manufactured

Space-qualified aspheres are produced with deterministic ultra-precision processes:- CNC Grinding for initial contour shaping.

- Computer-Controlled Optical Surfacing (CCOS) for mid-stage form correction.

- Magnetorheological Finishing (MRF) for final nanometer-scale polishing.

Precision Testing for Guaranteed Performance

Measurement is as critical as fabrication. For large-aperture optics, we use:- Full-Aperture Interferometry with compensator optics or computer-generated holographs (CGH) for nanoscale surface verification.

- Sub-Aperture Stitching Interferometry for oversized or deep aspheres without costly custom compensators.

- Multi-Parameter Metrology including surface roughness (as low as 0.2 nm), scratch-dig quality (20/10), and center thickness control to ensure alignment integrity.

Technical Performance Indicators

Parameter | Specification |

Diameter Range | 10 mm – 1000 mm |

Clear Aperture | ≥ 90% |

Surface Accuracy | RMS ≤ 1/200λ |

Surface Quality | 60/40 – 20/10 |

Materials | Zerodur, Fused Silica, H-K9L |

Surface Roughness | 0.2 nm |

Conic Coefficient Range | K = -1, -1 < K < 0, K < -1 |

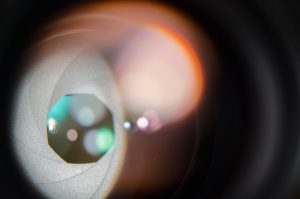

Applications in Space and Beyond

- Astronomical Telescopes: High-resolution observation with minimized aberration for wide-field and deep-sky imaging.

- Satellite Optical Systems: Remote sensing with reduced system mass and volume, maintaining clarity under orbital conditions.

- High-Energy Laser Systems: Beam shaping and focusing for directed energy or space-based material processing.

- Precision Imaging and LiDAR: Superior resolution and accuracy in ranging, mapping, and scientific instruments.

Why Aspherical Lenses Are the Best Choice for Space Optics

For space missions requiring superior imaging performance, light collection, and environmental resilience, the large-aperture aspherical lens is the recommended optical component. These lenses are not isolated elements but part of a closed-loop solution—encompassing design, ultra-precision manufacturing, and rigorous metrology—ensuring mission-critical performance in the most demanding aerospace applications.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!