Key Takeaways

- In ion trapping experiments, precision optics are critical for delivering UV laser excitation and collecting ion fluorescence efficiently.

- This application note details the design, manufacturing process, and practical performance of a custom microscope objective for ion trapping with a long working distance (≥52 mm) and high numerical aperture (NA ≥ 0.48).

- The system is optimized for multi-wavelength operation across 397 nm, 400 nm, and 632.8 nm bands and meets stringent diffraction-limited imaging criteria for quantum optical setups.

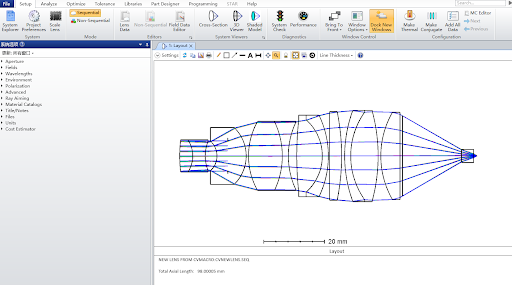

1. Optical Design: Balancing Resolution, Field of View, and Working Distance

The objective lens is engineered to achieve high resolution, wide field of view (2500 μm × 400 μm), and extended working distance while maintaining minimal aberrations across UV and visible wavelengths.🔹 Multi-Wavelength Aberration Correction

A cemented triplet configuration using crown and flint glass was selected to minimize chromatic aberration. Each of the three lens groups is tailored for 397 nm, 400 nm, and 632.8 nm wavelengths, achieving:- Chromatic aberration ≤ 0.02λ

- Spherical aberration, coma, and astigmatism correction through asymmetric curvatures and lens tilt optimization

🔹 Telecentric Optical System

To ensure uniform UV illumination, a telecentric imaging path was implemented, maintaining telecentricity within 5 mrad. This reduces intensity variation caused by object displacement—critical in ion array excitation.

🔹 Long Working Distance with High NA (High Numerical Aperture)

Achieving both NA = 0.49 and WD ≥ 52 mm required a three-stage optical configuration:

- Front: biconvex lens (expands incident pupil)

- Middle: meniscus lens (compensates for field curvature)

- Rear: plano-convex lens (shortens optical path)

This setup balances performance and integration flexibility within vacuum chambers and optical tables.

🔹 Transmission and Distortion Optimization

- High-transmittance optical glass (≥82% at 397 nm)

- Multilayer AR coatings (reflectivity ≤ 0.5%) deliver total transmission ≥85%

Distortion is kept below 0.2%, supporting high-accuracy imaging

Manufacturing Process: Achieving Ultra-Precision Tolerances

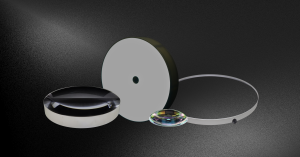

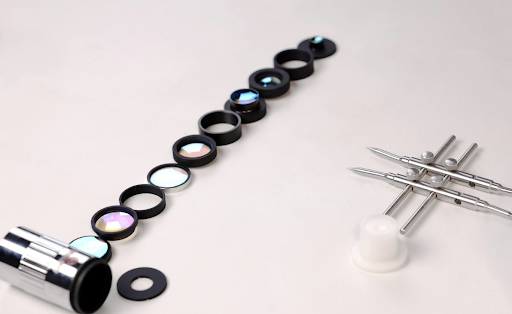

The objective lens consists of 12 spherical elements manufactured to exacting tolerances.🔹 Lens Fabrication

- CNC spherical grinding with real-time compensation: curvature accuracy ±0.001 mm

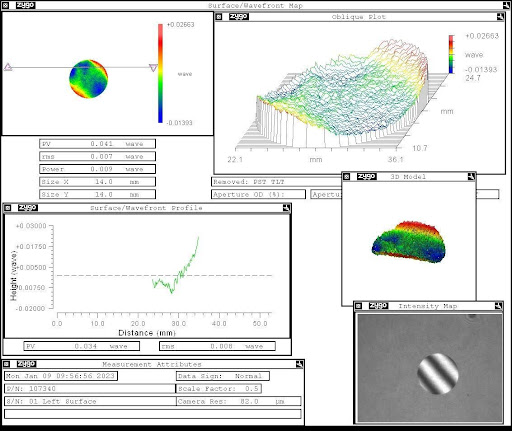

- Polishing with nano-alumina abrasives: surface roughness Ra ≤ 0.01 μm, flatness ≤ λ/10

- Bonding with UV-cured adhesive in Class 100 cleanroom: coaxiality ≤ 0.002 mm, bonding parallelism ≤ 5″

🔹 Thickness and Centering Precision

Laser interferometry ensures:- Thickness deviation ≤ ±0.002 mm

- Focal length deviation ≤ 0.1%

🔹 Coating and Assembly

- AR coating via vacuum magnetron sputtering with 11/9/7-layer stack designs for 397/400/632.8 nm

- Lens assembly under controlled temperature and humidity:

- Coaxiality ≤ 0.005 mm

- Center deviation ≤ 0.01 mm

Application in Ion Trap Systems: Enhanced Optical Performance

🔹 Dual Function: Laser Excitation and Fluorescence Imaging

- Field of view fully covers typical ion arrays (2000 μm × 300 μm)

- Laser intensity uniformity within ±3%

- Fluorescence collection efficiency improved by 40% over NA=0.3 designs

- Combined with ≥85% transmission, signal-to-noise ratio improves by 60%

🔹 High-Fidelity Imaging

- Imaging distortion ≤ 0.2% → positional error ≤ 5 μm

- Spot size ≤ 1.2 μm, enabling resolution of ions ≥2 μm apart

- In practical tests: 10 Ca⁺ ions resolved with positional repeatability of ±0.3 μm

🔹 System Integration and Reliability

- Working distance of 52 mm provides ample space for trap electrodes and vacuum chamber windows

Conclusion

This high-NA, long working distance microscope objective is a powerful optical solution for quantum computing, atomic physics, and UV-based fluorescence imaging systems. Combining advanced optical design, ultra-precision fabrication, and real-world experimental performance, it serves as a model for next-generation microscope objective design in complex laboratory environments.

Interested in Custom Objectives for Quantum or UV Applications?

Contact us today to discuss custom design options or explore our capabilities in long working distance and high-NA optical systems.

FAQs

1. What makes a microscope objective suitable for ion trap experiments?

A microscope objective for ion trap experiments must balance long working distance (typically ≥50 mm) with high numerical aperture (NA ≥ 0.48) to enable both UV laser excitation and efficient fluorescence collection. It should also offer multi-wavelength performance, diffraction-limited imaging, and minimal distortion to ensure precise ion localization and readout.

2. How does telecentric imaging benefit ion trapping applications?

Telecentric optical design maintains a constant magnification across the field of view, ensuring uniform laser intensity and accurate fluorescence measurement even when ions shift slightly in position. This improves both excitation consistency and signal reliability, which are critical in quantum computing and spectroscopy.

3. Can custom objective lenses be designed for 397nm and 400nm UV laser use?

Yes. Custom objective lenses can be precisely designed to operate at 397 nm and 400 nm by using carefully selected optical materials (such as crown and flint glass), optimized multi-layer AR coatings, and aspheric or multi-element configurations to minimize chromatic and spherical aberrations across the UV and visible spectrum.