Key Takeaways

- Meeting strict wavefront error (WFE) budgets is critical for space telescope optics, ensuring nanometer-level imaging accuracy and mission reliability. This article details practical strategies for managing WFE contributions from surface figure, alignment, coatings, and thermal effects.

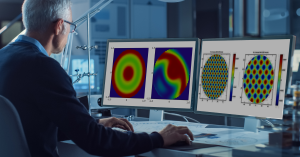

- Advanced metrology techniques, such as phase-shifting interferometry and stitching profilometry, support precise wavefront measurement.

- By integrating custom optical design, adaptive components, and early collaboration between designers and manufacturers, wavefront sensors and optical assemblies can achieve performance targets for telescope alignment, interferometer stabilization, and laser beam control in space systems.

How to Manage Wavefront Error Budgets in Space Telescopes

Meeting strict wavefront error (WFE) budgets is essential in the design and manufacturing of space telescope optics. These performance thresholds determine how clearly and accurately a telescope can capture images of distant celestial objects or monitor Earth from orbit. For optical manufacturers, maintaining ultra-low surface figure and irregularity isn’t just about precision—it’s about mission-critical reliability in the extreme conditions of space.

In this article, we’ll share practical insights from the manufacturing floor, highlighting how we deliver precision optics that meet the stringent demands of WFE budgets for small- and large-scale space systems.

What Is a Wavefront Error Budget?

A wavefront error budget is a system-level allocation of permissible optical aberrations across the components in an optical path. Typically expressed in nanometers RMS, it includes contributions from:- Optical surface figure and irregularity

- Alignment tolerances

- Coating-induced stress

- Thermal and mechanical deformation

Manufacturing Challenges in Meeting WFE Budgets

1. Tight Surface Figure Tolerances

Achieving ultra-precise surface figure accuracy is often the largest contributor to total WFE. Optics must conform to highly specific shapes—spherical, aspheric, off-axis parabolas—with nanometer-level accuracy.

✅ Solution: We use computer-controlled polishing (CCP), sub-aperture tools, and deterministic figuring guided by interferometric metrology. This ensures we hit surface figure targets without compromising slope or edge transitions.

2. Controlling Optical Surface Irregularity

Surface irregularity, particularly high-frequency errors, can scatter light and degrade imaging performance. These are often the trickiest part of the spec to control.

✅ Solution: Magnetorheological finishing (MRF) and ion beam figuring (IBF) allow us to eliminate mid- and high-spatial frequency errors without introducing new artifacts, ensuring the optical surface remains clean and uniform.

3. Managing Coating-Induced Deformation

Thin-film optical coatings—essential for reflectivity or transmission—can warp optics due to residual stress, subtly distorting wavefronts.

✅ Solution: We simulate coating stress during design and apply symmetrical or balanced coatings when possible. In-situ monitoring helps us catch and correct distortions early.

4. Material Selection for Thermal Stability

Materials with poor thermal behavior can shift figure under orbital temperature changes, exceeding WFE tolerances after launch.

✅ Solution: We recommend ultra-low CTE substrates like Zerodur®, ULE®, or SiC for space-bound optics and verify their performance through finite element thermal modeling and environmental testing.

Verifying Wavefront Quality with Advanced Metrology

Achieving nanometer-level surface precision is only possible with equally precise measurement tools. We use:- Phase-shifting interferometry for full-aperture WFE measurement

- Stitching profilometry for aspheres and large optics

- Custom CGHs or deflectometry for off-axis and freeform optics

Partnering with Designers on WFE Budget Allocation

The most efficient projects involve early collaboration between system engineers and optical manufacturers. By reviewing the full wavefront error budget together, Avantier can suggest trade-offs—such as relaxing certain specs to improve alignment tolerances—based on practical manufacturing capabilities.

Conclusion: Precision Manufacturing for Mission-Critical Optics

Meeting wavefront error budgets in space telescope optics requires more than just precision polishing—it demands a closed-loop process of design-for-manufacturing, advanced metrology, and deep material knowledge. As your manufacturing partner, we bring the tools and expertise to ensure every optic we deliver meets the mission’s performance targets, from launch to orbit.

Looking for a partner with proven expertise in space-qualified optical components? Contact us to discuss your next mission.

GREAT ARTICLE!

Share this article to gain insights from your connections!