Key Takeaways:

- The integrity of any optical system designed for space, defense, or high-energy applications hinges entirely on selecting the right durable optical materials.

- For engineers in telescope manufacturing and satellite payload design, the challenge is twofold: achieving dimensional stability using thermally stable substrates against extreme thermal cycling, and maintaining clarity via radiation-hardened coatings under sustained radiation exposure.

- This guide addresses the critical material trade-offs—from low-CTE substrates like Zerodur to specialized high-temperature focal lens materials—and provides a technical selection framework.

- Dive in to leverage our comparative material table and ensure your system’s long-term resilience in the harshest environments.

Durable Optical Materials For Harsh Environments

Modern optical systems are increasingly deployed in harsh environments, from the vacuum of outer space and high-radiation zones to settings with extreme thermal volatility. These demanding conditions place extraordinary stresses on optical components, requiring continuous innovation in the selection of durable optical materials, the resilience of coatings, and overall optical design. This article explores the critical role of durable optical materials in guaranteeing reliable optical performance under such challenges, highlighting key technologies such as radiation-hardened coatings, thermally stable substrates, and innovative meta-optics.

Why Durable Optical Materials Are Essential

The success of next-generation optical systems depends on durable optical materials engineered to perform reliably in harsh environments. From withstanding ionizing radiation to maintaining dimensional stability amid extreme temperature shifts, these advanced materials enable high-performance, resilient optics. Innovations such as radiation-hardened coatings, ultra-stable substrates like Zerodur and Silicon Carbide (SiC), and cutting-edge meta-optics are equipping engineers to design systems that thrive under the most demanding conditions.

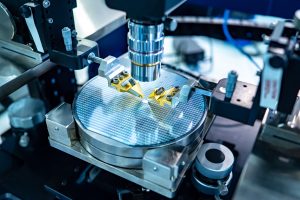

1. Thermally Stable Durable Optical Materials

Thermal fluctuations can severely distort optical surfaces, leading to misalignments and degraded image quality. To mitigate these effects, the use of thermally stable durable optical materials for substrates is crucial in the design of precision optics. These advanced materials materials play a key role in providing this stability.

- Zerodur: This glass-ceramic, developed by SCHOTT, is characterized by its near-zero thermal expansion and exceptional long-term dimensional stability. Zerodur, a prime example of a durable optical material, is widely used in applications such as astronomical telescopes, metrology systems, and satellite optics.

- ULE (Ultra-Low Expansion glass): Manufactured by Corning, ULE offers a similarly low coefficient of thermal expansion (CTE), making it an ideal durable optical material for optical benches and spaceborne instruments.

- Silicon Carbide (SiC): Silicon carbide is valued for its high stiffness-to-weight ratio, high thermal conductivity, and mechanical robustness. SiC optics, known for their durability, are frequently used in high-speed scanning systems, infrared imaging systems, and aerospace applications.

These thermally stable materials are often integrated with techniques like lightweighting, bonded structures, and active thermal control systems to ensure consistent performance across a wide range of environmental conditions.

Comparative Table: Thermally Stable Durable Optical Materials

Material | Typical Applications | Systems in Use | CTE (10⁻⁶/K) | Strength | Radiation Resistance | Outgassing |

Zerodur | Telescopes, Semiconductor, Aerospace, High-energy lasers | Astronomical Optics, Semiconductor, Optical Communication | ~0 | Moderate | High | Low |

ULE | Semiconductor, Telescopes, High-precision optics | Astronomical Optics, Semiconductor | ~0 | Moderate | High | Low |

Silicon Carbide | Power electronics, Renewable energy, Defense, High-temperature apps | Power Systems | 2.2–4.0 | High | High | Low |

Chalcogenide Glass | Infrared optics, Thermal imaging, Automotive, Medical sensing | Thermal Imaging Systems, Optical Communication | 20–25 | Moderate | Moderate | Moderate |

2. Radiation Hardened Coatings for Enhanced Optical Durability

Radiation can significantly degrade the performance of optical components, causing transmission loss, coating delamination, or surface contamination. This is a critical concern for optical systems in space, nuclear inspection tools, and medical imaging systems exposed to ionizing radiation. To mitigate these risks, radiation-hardened coatings, based on advanced materials technology, are engineered to resist damage from high-energy particles.

These coatings often utilize:

- Inorganic dielectric materials such as hafnium oxide (HfO2), aluminum oxide (Al2O3), and silica (SiO2) for their high damage thresholds and chemical stability.

- Ion-assisted deposition (IAD) and atomic layer deposition (ALD) techniques to produce dense, defect-free layers with strong adhesion to substrates.

- Multi-layer architectures designed to combine reflectivity, durability, and wavelength-specific performance.

Radiation-hardened coatings are essential for maintaining the optical clarity and functionality – and thus the durability – of systems in satellites, deep-space telescopes, fusion reactors, and particle accelerators.

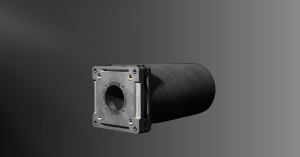

3. Meta-Optics and Nanophotonic Structures: Compact and Durable Optical Solutions

As optical systems become smaller and are required to perform more functions, traditional refractive and reflective designs face limitations in terms of size, weight, and adaptability. Meta-optics and nanophotonic structures offer a revolutionary alternative by manipulating light at the subwavelength scale. These represent an innovative class of durable optical materials and structures that are transforming optical design.

Meta-optics employ precisely engineered nanostructures, often patterned on flat surfaces, to achieve optical functions like focusing, filtering, polarization control, and beam shaping. This can eliminate the need for bulky lenses or mirrors.

Key benefits include:

- Reduced size and weight, enabling integration into compact devices such as small satellite payloads, UAVs, and portable sensors where durable, lightweight optics are paramount.

- Enhanced functionality, including tunable focal lengths, broadband performance, and multifunctional components integrated into a single layer.

- Increased robustness, as meta-surfaces can be fabricated using radiation-resistant materials (a hallmark of durable optical materials) and encapsulated for environmental protection.

The applications of nanophotonics and meta-optics are expanding rapidly in fields like defense, augmented reality, biomedical imaging, and space optics. In each of these applications compactness and performance under extreme conditions are critical, and advanced durable optical materials are essential.

4. Additional Considerations for Durable Optical Materials in Harsh Environments

Beyond the specific material categories, several additional factors are crucial when selecting durable optical materials for harsh environments:

- Mechanical and Environmental Testing: Advanced materials must withstand not only radiation and temperature changes but also mechanical shock, vibration, and pressure extremes. Testing protocols like MIL-STD-810 and ESA ECSS standards are used to validate optical components for aerospace and defense applications. Typical tests include thermal cycling, vibration, shock, and radiation exposure to ensure mission reliability and material durability.

- Outgassing and Contamination Resistance: In vacuum environments, even minimal outgassing from materials can lead to film deposition on optical surfaces, causing severe degradation. Advanced materials with low outgassing properties and chemical inertness, such as ULE and Zerodur, are favored for space optics and cleanroom applications.

- Adhesives and Bonding Techniques: Structural adhesives and bonding agents are critical for the stability of optical assemblies. In harsh environments, it’s essential to use low-outgassing epoxies, radiation-resistant glues, or optical contacting methods to ensure the durability of bonds and prevent stress-induced failures and contamination.

- Manufacturability and Cost Trade-Offs: While advanced materials like silicon carbide and nanophotonic metasurfaces offer excellent performance, they often involve complex fabrication processes, limited supplier availability, or low production yields, leading to higher costs. Design-for-manufacturing (DFM) considerations are essential to balance performance requirements with cost and scalability when selecting durable optical materials.

5. Future Directions in Durable Optical Materials

The field of durable optical materials is constantly evolving to meet increasingly demanding mission requirements. Key areas of innovation include:

- Chalcogenide glasses: For robust, durable IR optics in thermal imaging and harsh industrial environments.

- Phase-change metasurfaces: Utilizing materials like GeSbTe (GST) to create dynamically tunable and durable optics.

- Hybrid nanostructures: Combining meta-optics with conventional optical elements to expand bandwidth or field of view while maintaining durability.

- AI-driven inverse design tools: Employing artificial intelligence algorithms to optimize durable optical materials and structures for maximum resilience and efficiency.

Real-World Applications: Durable Optical Materials in Action

Durable optical materials for harsh environments are transforming the capabilities of optical systems across various sectors, ensuring they can operate reliably in the most extreme conditions. These materials are critical for maintaining system performance in environments exposed to extreme radiation, temperature variations, mechanical stresses, and other harsh conditions. Below are some key real-world applications.

Mars Science Laboratory ChemCam Optical Fiber Assemblies: A Testament to Durable Optical Design

One of the most compelling examples of durable optical materials successfully deployed in harsh environments comes from NASA’s Mars Science Laboratory (MSL) ChemCam instrument, part of the Mars rover mission. The optical fiber assemblies used in ChemCam needed to withstand the extreme thermal and radiation conditions on Mars, along with the mechanical stresses of launch and operation – a true test of material durability.

Key challenges demanding highly durable optical materials included:

- Operating in temperatures ranging from –143°C to +110°C, which represents the temperature extremes on Mars as well as spacecraft conditions.

- Enduring significant radiation exposure from both the Martian environment and space travel.

- Withstanding mechanical flexing and vibration during rover movements.

To meet these challenges, the team selected durable optical materials such as AVIM connectors and W.L. Gore FLEXLITE cables, which provided superior thermal and mechanical properties. These materials were tested rigorously to ensure reliability and durability in Mars’ harsh conditions. The result was a robust optical system capable of delivering high performance, even in the most demanding conditions (source: NASA, Mars Science Laboratory).

Other Real-World Applications Demonstrating the Need for Durable Optical Materials:

- James Webb Space Telescope: Utilizes beryllium mirrors and silicon carbide (SiC) components, both highly durable optical materials, to ensure thermal and mechanical stability in the vacuum of space.

- DARPA’s EXTREME Program: Explores meta-optics, focusing on durable optical materials for compact, multifunctional sensing in defense technologies.

- ESA’s Sentinel-5P Satellite: Employs Zerodur-based spectrometer optics, a durable optical material chosen for its dimensional stability against extreme temperature fluctuations in Earth’s orbit.

- Mars Rover Optics (General): Beyond ChemCam, Mars Rovers utilize radiation-hardened coatings and low-outgassing adhesives—components of durable optical systems—to ensure reliable optical performance.

- Nuclear Reactor Inspection: Leverages SiC optics and radiation-resistant coatings, types of durable optical materials essential for imaging in high-energy, high-temperature environments.

Sustainability and Lifecycle Considerations for Durable Optical Materials

As the use of durable optical materials expands, it’s increasingly important to consider their environmental impact and lifecycle durability. Materials with high durability and long lifespans inherently reduce waste and mission risk. Efforts are underway to improve the recyclability and reduce the environmental footprint of both substrates and coatings used in these durable optical solutions.

Key Recommendations for Selecting Durable Optical Materials

- Choose durable optical materials with proven performance in the specific target environment (e.g., Zerodur or ULE for thermal stability, SiC for mechanical strength and durability).

- Use radiation-hardened coatings and low-outgassing adhesives to enhance the durability of optical systems for space and nuclear applications.

- Consider manufacturability and supply chain factors early in the design process when selecting durable optical materials.

- Incorporate meta-optics or nanophotonics for size, weight, and multifunctionality where the application demands compact, durable optical components.

- Validate designs through rigorous environmental and mechanical testing to confirm the chosen durable optical materials meet all operational requirements.

Conclusion: The Indispensable Role of Durable Optical Materials in the Future of Optical Systems

Advances in durable optical materials for harsh environments are transforming the way optical systems are designed and deployed. With innovations like radiation-hardened coatings, thermally stable substrates, and resilient meta-optics, optical systems can now operate reliably and effectively in extreme conditions, from the depths of space to the harshest industrial environments. As mission demands become more ambitious and environments more hostile, the need for these robust and durable optical materials will continue to drive innovation in aerospace, defense, energy, and scientific research sectors.

By selecting durable optical materials and design solutions, engineers can create optical systems that perform optimally under the most challenging conditions and enable breakthroughs across a wide range of applications.

Citation:

NASA. (2012). Mars Science Laboratory (MSL) ChemCam Optical Fiber Assemblies. Retrieved from https://mars.jpl.nasa.gov/msl/

GREAT ARTICLE!

Share this article to gain insights from your connections!