Industrial Image Processing Case Study: Dual-Camera Stitching for Conveyor Belt Inspection

Introduction

In the transportation and logistics industry, image processing plays a crucial role in quality control and automation. This case study explores how Avantier Inc. developed a custom software solution for a client requiring high-resolution images of boxes moving at high speeds on a conveyor belt.

The challenge was significant: two cameras had to capture different parts of the moving boxes and merge them into a single, accurate image. Our engineering team created a fully automated solution that combined geometric transformations, brightness adjustments, and stitching algorithms to deliver seamless results.

The Challenge: Capturing Moving Boxes on a Conveyor Belt

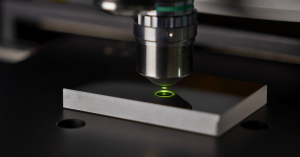

The client installed two video cameras positioned close to a conveyor belt carrying boxes. While this setup provided sufficient resolution, each camera could only capture part of the belt’s cross-section.

- Camera placement: Both cameras were mounted on the sides of the belt.

- Objective: The client wanted clear, detailed images of the box textures on the top surface.

- Problem: Since each camera viewed the boxes at different angles and distances, their images needed to be aligned and stitched into one common frame.

The Technical Solution: Transforming Images into a Common Coordinate System

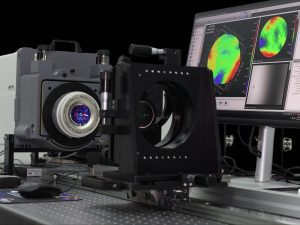

To merge the images, our engineers had to solve the problem of camera geometry. The raw outputs existed in different coordinate systems, making direct stitching impossible.

Our solution:

- Applied geometric transformations to map both images into a single XYZ coordinate plane.

- Designed software that performed these transformations automatically based on the known relative camera positions to the conveyor belt.

- Eliminated the need for manual operator intervention, ensuring a reliable and efficient workflow.

Brightness & Alignment Adjustments

Even after geometric transformation, the images from both cameras displayed two common issues:

- Shifts in alignment within the merged plane.

- Brightness variations between the left and right camera feeds.

To address this:

- Our algorithms compensated for brightness differences, ensuring uniform image quality.

- A precision alignment correction shifted the left and right images to achieve pixel-level synchronization.

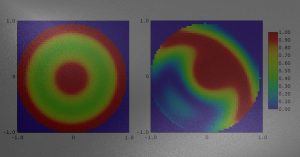

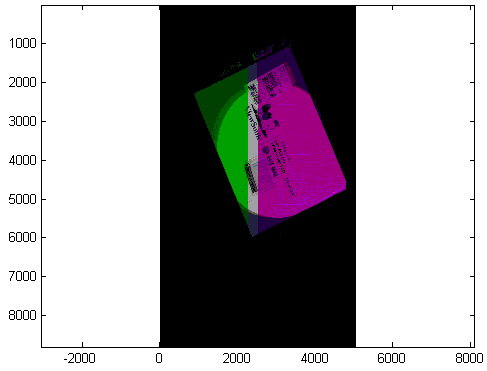

The false-color analysis confirmed that the overlapping regions aligned well, with only minimal edge fringes around digits and stripes—evidence of high stitching accuracy.

Results: Seamless Image Stitching

The stitched grayscale images produced a unified, high-resolution view of the conveyor belt.

- Successful case: Overlap regions appeared predominantly gray, showing excellent stitching.

- Comparison case: Unsuccessful stitching attempts (without corrections) demonstrated noticeable misalignments and color fringes.

This validation proved the robustness of Avantier’s algorithm in handling multi-megapixel images from different camera angles.

Why This Matters for the Transportation Industry

Accurate image processing is critical for automated inspection, quality control, and operational efficiency. In this case, seamless stitching enabled the client to:

- Obtain high-quality images of box textures at high conveyor speeds.

- Reduce human error by automating image correction and alignment.

- Improve throughput and inspection accuracy, directly impacting productivity.

Avantier’s Expertise in Industrial Image Processing

Avantier Inc. specializes in solving complex imaging challenges. Our team’s ability to integrate geometric modeling, computer vision, and automation ensures that clients across industries benefit from tailored, reliable solutions.

This case study highlights not just a single technical achievement, but our broader capability to develop scalable image processing software for industrial applications.

Related Content

GREAT ARTICLE!

Share this article to gain insights from your connections!