Key Takeaways

- Optical systems designed with meticulous attention to field of view parameters.

- Analysis tools utilized to ensure optimal field of view performance.

- Optimization techniques employed to meet specified field of view requirements effectively.

Maximizing Optical System Performance with Zemax

At Avantier, we use Zemax for designing, analyzing, and optimizing optical systems, such as lenses, objectives, cameras, and other optical devices.

For optical system design, Zemax helps to construct a virtual optical system by defining optical specifications, such as surface curvatures, thickness, refractive indices, etc.

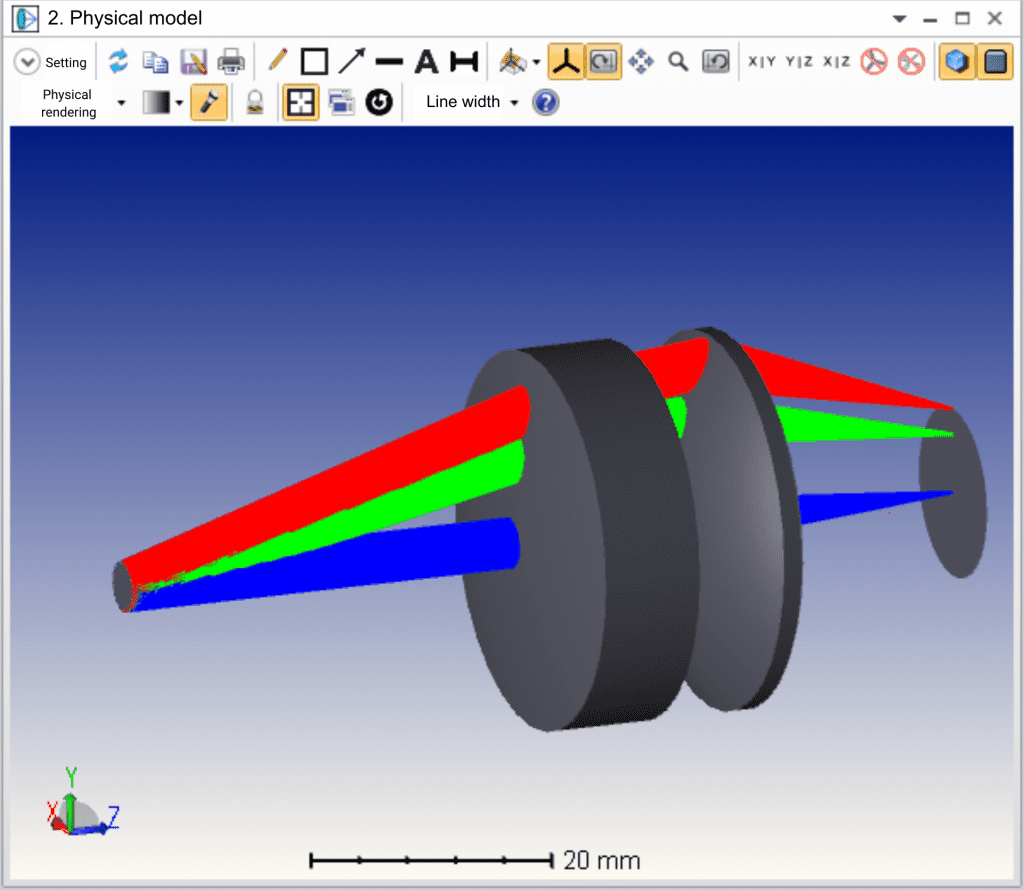

For ray tracing, Zemax simulates the propagation of light rays through the optical system and helps evaluate the imaging performance of the system.

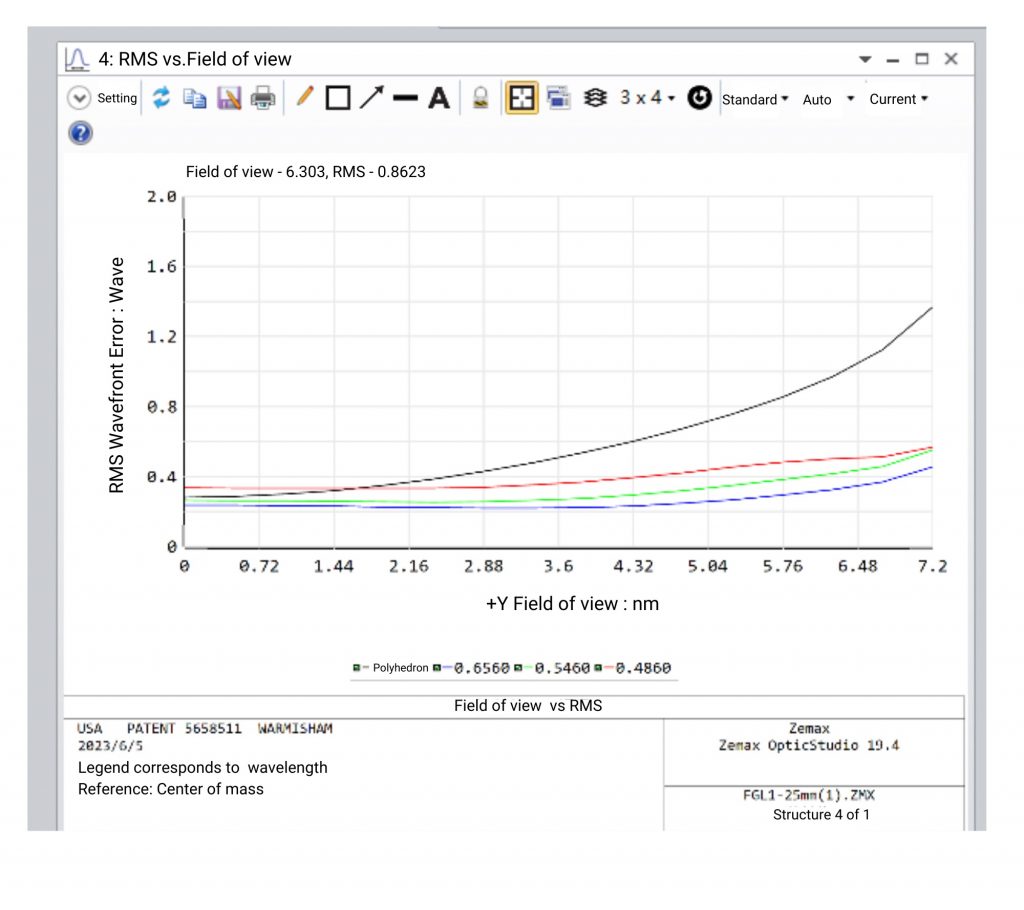

For analysis, Zemax offers various analysis tools to evaluate, such as can calculate parameters like wavefront errors, MTF, etc.

For optimization, Zemax has the capabilities to improve performance, such as Zemax can automatically adjust the variables (like lens positions, and curvatures) to find the optimal configuration that meets the desired criteria after specifying optimization goals.

For tolerancing, Zemax allows performing tolerance analysis to assess the impact of manufacturing and alignment errors on system performance.

Challenges and Strategies in Optical System Design and Manufacturing

Optical technology has become ubiquitous in modern applications, ranging from cameras and telescopes to medical devices and automotive sensors. Nevertheless, crafting these systems poses significant challenges for engineers, notably in rectifying optical flaws and meeting precise specifications.

Correcting optical aberrations stands out as a formidable task in the realm of optical engineering. These aberrations, which cause image distortion or blurring, stem from factors like lens curvature, material properties, and refractive indices. Overcoming such imperfections demands a profound grasp of optics, sophisticated mathematical models, and advanced manufacturing methodologies.

Addressing optical aberrations involves leveraging both geometrical optics and ray tracing techniques. While geometrical optics simplifies light behavior modeling within optical setups, ray tracing delves deeper, considering material refractive indices.

The design journey to rectify optical aberrations entails meticulous steps. Engineers first establish imaging quality requisites, encompassing parameters such as focal length and field of view. They then utilize optical design software to generate initial designs, employing aberration theory to forecast expected flaws.

Refinement of these designs hinges on a merit function—a mathematical tool assessing the variance between desired and actual imaging quality. Engineers iteratively adjust parameters until the system meets the predefined specifications.

Attaining stringent tolerances represents another formidable aspect of optical engineering. These systems must adhere strictly to accuracy, precision, and repeatability criteria. Achieving such exactness necessitates specialized equipment and expertise across precision engineering, machining, and metrology domains.

The optical manufacturing supply chain, intricate and global, spans multiple nations. Raw materials, including glass, plastics, and metals, are sourced globally. Manufacturing entails diverse processes like lens grinding, polishing, and surface coating with anti-reflective materials, culminating in optical system assembly.

Future Trends and Innovations in Optical System Design and Manufacturing

In conclusion, designing and manufacturing optical systems is a complex and challenging process. Correcting optical aberrations and achieving tight tolerances require a deep understanding of optics, advanced mathematical models, and sophisticated manufacturing techniques. As demand for optical systems continues to grow on a large scale, the supply chain and manufacturing industry will continue to evolve and improve to meet the demands of the market.

GREAT ARTICLE!

Share this article to gain insights from your connections!