Key Takeaways

- Cylindrical lens performance depends on surface profile accuracy, curvature radius precision, and transmitted wavefront quality.

- Utilizing a mix of contact profilometry for high-roughness parts and non-contact ZYGO interferometry for ultra-high-precision (PV 0.05λ) ensures compliance with ISO 10110-5 standards.

- Beyond geometry, wavefront sensing and MTF testing are critical to verifying imaging resolution and contrast.

- A systematic metrology framework is essential for minimizing aberrations in laser shaping and high-speed scanning applications.

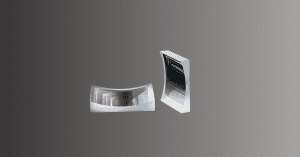

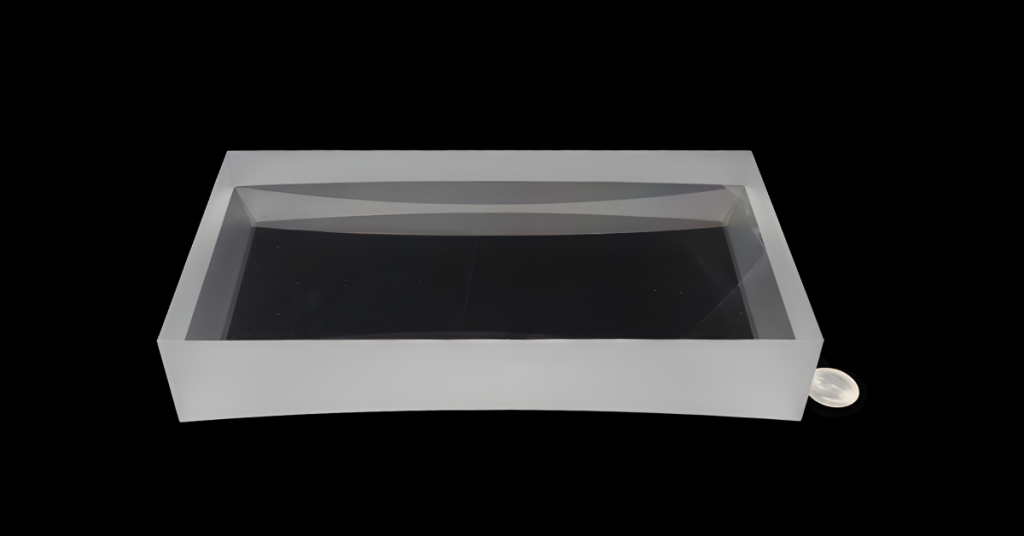

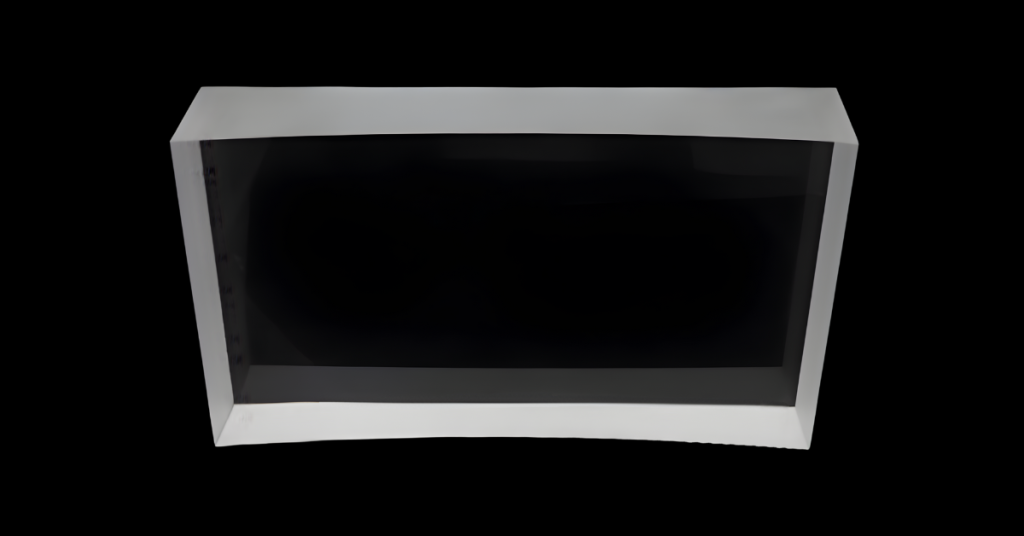

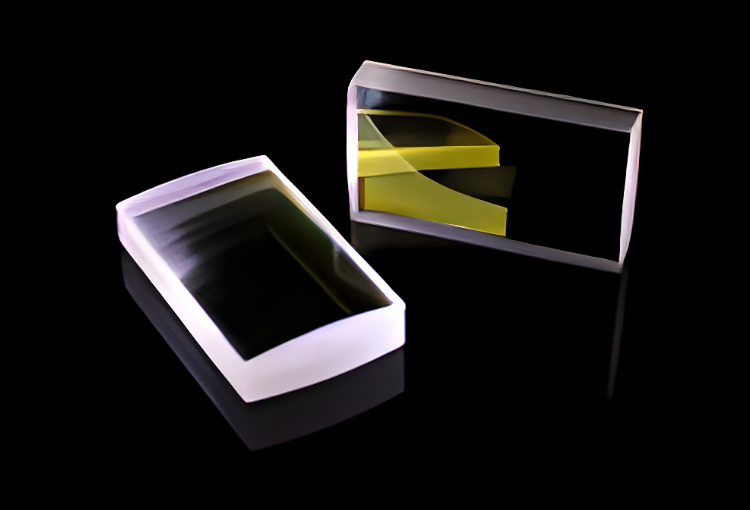

As non-spherical optical elements with uniaxial rotational symmetry, cylindrical lenses play an indispensable role in laser beam shaping, linear array scanning, spectral analysis, and optical fiber communications.

Unlike spherical lenses, which focus light to a single point, cylindrical lenses focus incident light onto a focal line. This unique geometry introduces distinct manufacturing and metrology challenges. Key performance metrics—including beam quality, imaging resolution, and energy distribution—are dictated by surface profile accuracy, curvature radius precision, and transmitted wavefront quality. Consequently, a systematic and efficient testing framework is essential for high-end application compliance.

I. Surface Profile and Curvature Radius: Ensuring Geometric Precision

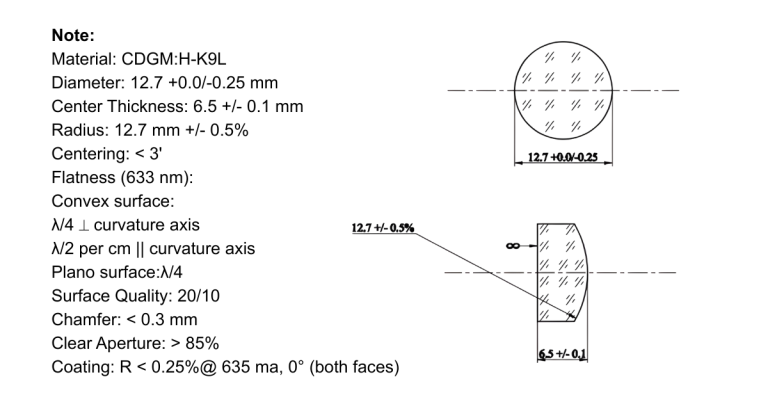

The profile and curvature radius are the foundational geometric parameters of a cylindrical lens, determining its optical power and aberration characteristics. Unlike the symmetrical inspection of spherical optics, cylindrical metrology requires stringent control over the generatrix direction and the orientation of the rotational symmetry axis.1.1 Contact Profilometry

This method utilizes a physical probe to scan along the cylindrical generatrix, directly acquiring contour data to calculate the curvature radius.- Advantages: Direct data acquisition without complex optical conversion; ideal for lenses with high surface roughness or very large curvature radii (R values). It is highly efficient for parts with an S/D 60-40 cosmetic grade.

- Limitations: Risk of surface micro-scratches on sensitive coatings; reduced accuracy for small radii where high-precision tolerances (e.g., ±0.1%) are required.

1.2 Optical Profiling (Non-Contact)

Using white-light interferometry or confocal microscopy, this method captures high-resolution 3D profiles along the cylindrical axis.- Performance: Highly sensitive to mid-to-high frequency errors and localized defects.

- Application: Ideal for mid-to-high-end lenses requiring surface accuracy of λ/8 (λ = 632.8 nm). Its non-destructive nature makes it the industry standard for mass production.

1.3 Interferometric Measurement (Cylindrical Reference)

By employing a cylindrical wavefront reference—such as a cylindrical test plate or Computer-Generated Hologram (CGH)—this method utilizes the zero-interference principle.- Precision: Achieves a curvature radius accuracy of ± 0.01 mm and surface profile (PV) accuracy of 0.05λ.

- Technical Challenge: Requires precise alignment of the cylindrical axis (typically within ± 0.5 arc minutes). This method is fully compliant with ISO 10110-5 standards.

1.4 Collimator Tilt Detection

Primarily used for lenses with long curvature radii (R > 1000 mm), this method calculates the radius through inclined scanning and geometric modeling. While computationally complex, it serves as a vital auxiliary tool for specialized scientific research samples.

II. Wavefront Detection: Verifying Optical System Performance

Wavefront quality directly impacts how a cylindrical lens performs in a real-world system, specifically regarding asymmetric aberrations like astigmatism and coma.2.1 Interferometric Through-Beam Testing

Based on Twyman-Green or Fizeau interferometry, the lens’s optical power is nulled by a cylindrical reference wavefront. The residual distortion is then analyzed.- Accuracy: Detection accuracy reaches RMS λ/50, complying with ISO 14999-4. This is the benchmark for scientific-grade factory inspections.

2.2 Shack-Hartmann Wavefront Sensing

This method reconstructs the wavefront distribution by measuring the slope field of light after it passes through the lens.- Versatility: Excellent for large-aperture lenses (≤ 350 mm) and complex conjugate optical paths. It does not require complex reference calibration, making it ideal for rapid on-site verification.

2.3 Modulation Transfer Function (MTF) Testing

MTF testing evaluates imaging resolution and contrast along the arc and tangential directions.- Impact: For laser line generators, MTF determines line sharpness and uniformity. For line-scan cameras, it ensures scanning resolution.

- Standardization: Conducted in strict accordance with GB/T 26332-2010 (Optical Transfer Function Measurement), providing customers with direct performance benchmarks for system integration.

III. Professional Metrology Capabilities and Equipment

Precision measurement of cylindrical optics is a multidisciplinary discipline involving geometric optics, interferometry, and digital signal processing. Given the unique challenges of single-axis symmetry, Avantier has established a comprehensive measurement ecosystem. Our facility integrates ZYGO interferometers with specialized cylindrical reference optics to form a world-class inspection platform.- Light Source: 632.8 nm Helium-Neon (HeNe) laser.

- Repeatability: RMS repeatability of λ/10,000 and PV repeatability better than λ/300.

- Accuracy: Surface profile accuracy of PV 0.05λ, ensuring full compliance with ISO 10110-5.

Ready to Elevate Your Optical System Performance?

At Avantier, we combine decades of manufacturing expertise with world-class metrology to deliver cylindrical lenses that exceed industry standards. Whether you require high-volume production or custom scientific-grade optics, our ZYGO-certified testing framework ensures your components perform with absolute precision from day one. Contact our engineering team today to discuss your project specifications or to request a detailed technical consultation and quote for your next high-performance optical assembly.

GREAT ARTICLE!

Share this article to gain insights from your connections!