Key Takeaways:

- Micro-optics are essential in diverse fields, from microscopy to laser devices. Types of micro optics such as microlens arrays, microspheres, and micro mirrors serve specific functions like focusing light and steering light beams.

- Advanced manufacturing and precise metrology are crucial for producing high-quality micro-optical components, provided by companies like Avantier.

Types of Micro Optics

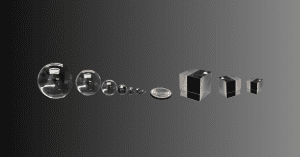

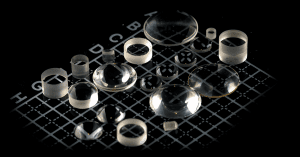

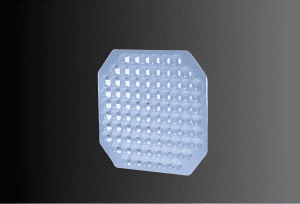

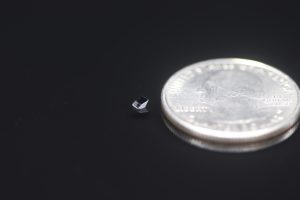

Micro-optics, ranging from a few micrometers to several millimeters in size, are tiny but powerful tools. These tools include microlens arrays, microspheres, waveplates, mirrors, and prisms. Microlens arrays find a wide range of applications in microscopes, cameras, 3D imaging sensors, and LiDAR systems. Meanwhile, microspheres excel at channeling light in optical fibers and confined spaces due to their near-perfect coupling ability. Consequently, all these high-precision micro-optical components are created using specialized micro-manufacturing techniques.

Moreover, most micro-optics utilize exactly the same foundations of physical optics as are used in large optical components – for example, refraction or reflection of light.

Micro-optical components are commonly used in smaller and lighter laser devices, imaging systems, medical instruments, display devices, endoscopy, etc. However, applications of micro optics continue to expand as technology advances. The most common micro-optical components and their application examples are as follows:

- Microlenses: microlenses are commonly used for focusing or collimating laser light, laser-to-fiber coupling, fiber-to-fiber coupling, reducing LED view angle, increasing light collection efficiency of detectors, and reducing the dimensions of optical systems. An example: microlenses are used in virtual reality (VR) and augmented reality (AR) headsets to focus and magnify images displayed on tiny screens or microdisplays. They enhance the visual experience by correcting distortions and improving the clarity of the virtual environment.

-

- Microlenses: microlenses are commonly used for focusing or collimating laser light, laser-to-fiber coupling, fiber-to-fiber coupling, reducing LED view angle, increasing light collection efficiency of detectors, and reducing the dimensions of optical systems. An example: microlenses are used in virtual reality (VR) and augmented reality (AR) headsets to focus and magnify images displayed on tiny screens or microdisplays. They enhance the visual experience by correcting distortions and improving the clarity of the virtual environment.

- Micro mirrors: micro mirrors are small mirrors that can be used to steer/fold light beams for applications in miniaturized laser scanning, very compact displays, smaller and lighter medical devices, etc. Micro mirrors work based on the same principles as large mirrors; they usually have a reflective coating which is either metallic or a dielectric multilayer structure. An example: in microscopy, a micro (dichroic) mirror is employed to reflect a certain wavelength and transmit other wavelengths.

Advanced Manufacturing and Metrology for Micro-Optics

The fabrication, testing, and characterization of micro-optics generally need sophisticated manufacturing processes and advanced metrology. Avantier utilizes the industry’s top-class manufacturing technology and state-of-the-art metrology to produce various types of micro optical components including microlenses, prisms, mirrors, beam splitters, and diffusers. Various coatings such as AR coatings and bandpass filters and reflective coating can be applied to the optical surfaces for enhancing the optical system performance. Micro-optical elements sometimes are produced in the form of arrays.

Avantier also produces microlens arrays, prism arrays capable of handling high power levels, providing exceptional performance. Contact us today for your next project.

GREAT ARTICLE!

Share this article to gain insights from your connections!